Automatic reforming device for buried oil tank lining

An oil tank and inner lining technology, which is applied in the field of buried oil tank lining automation equipment, can solve problems such as difficult construction, different shapes of oil tank volumes, and high safety risks for personnel, so as to avoid long-term construction and reduce downtime. The number of tanks and the effect of automatic transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

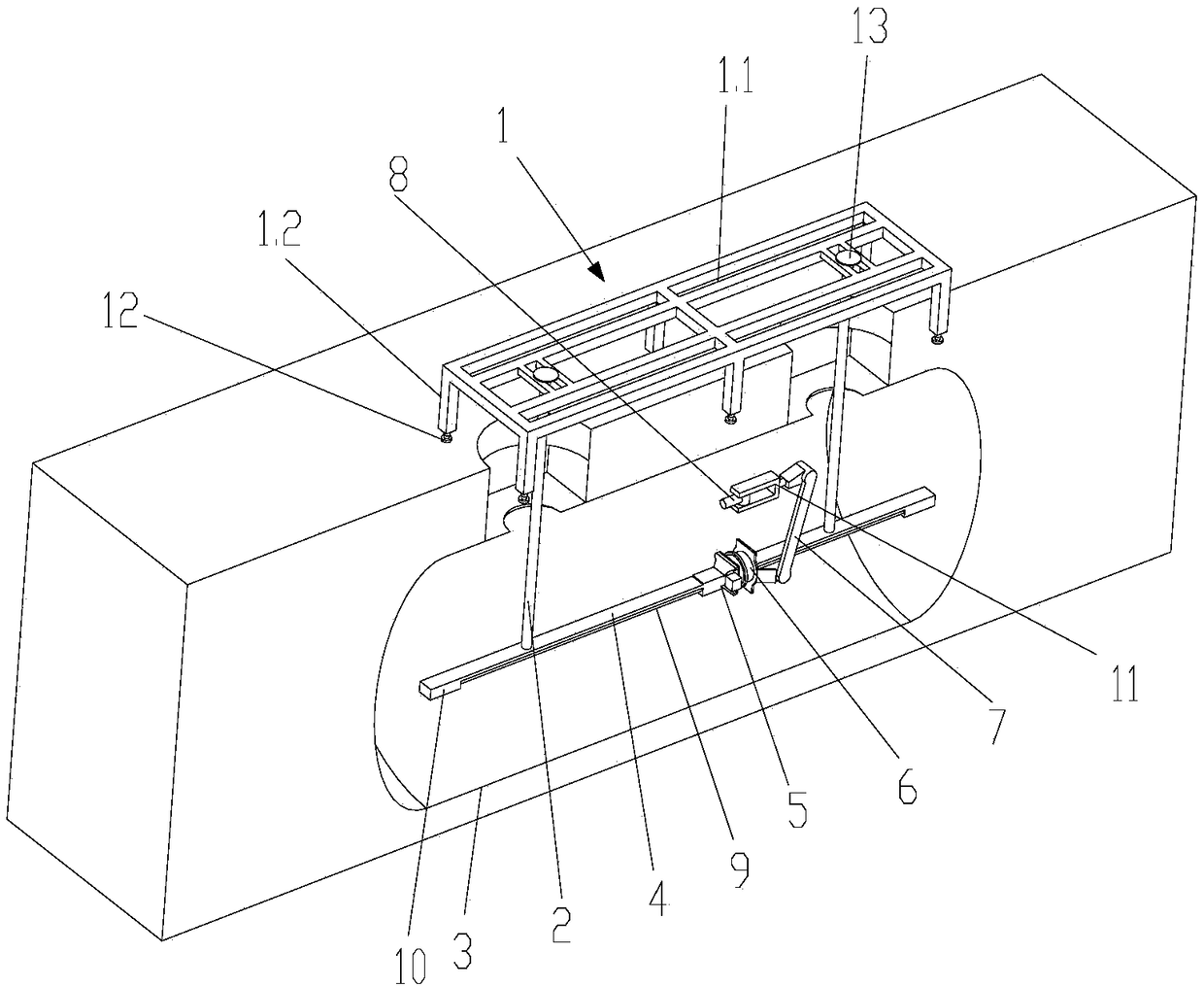

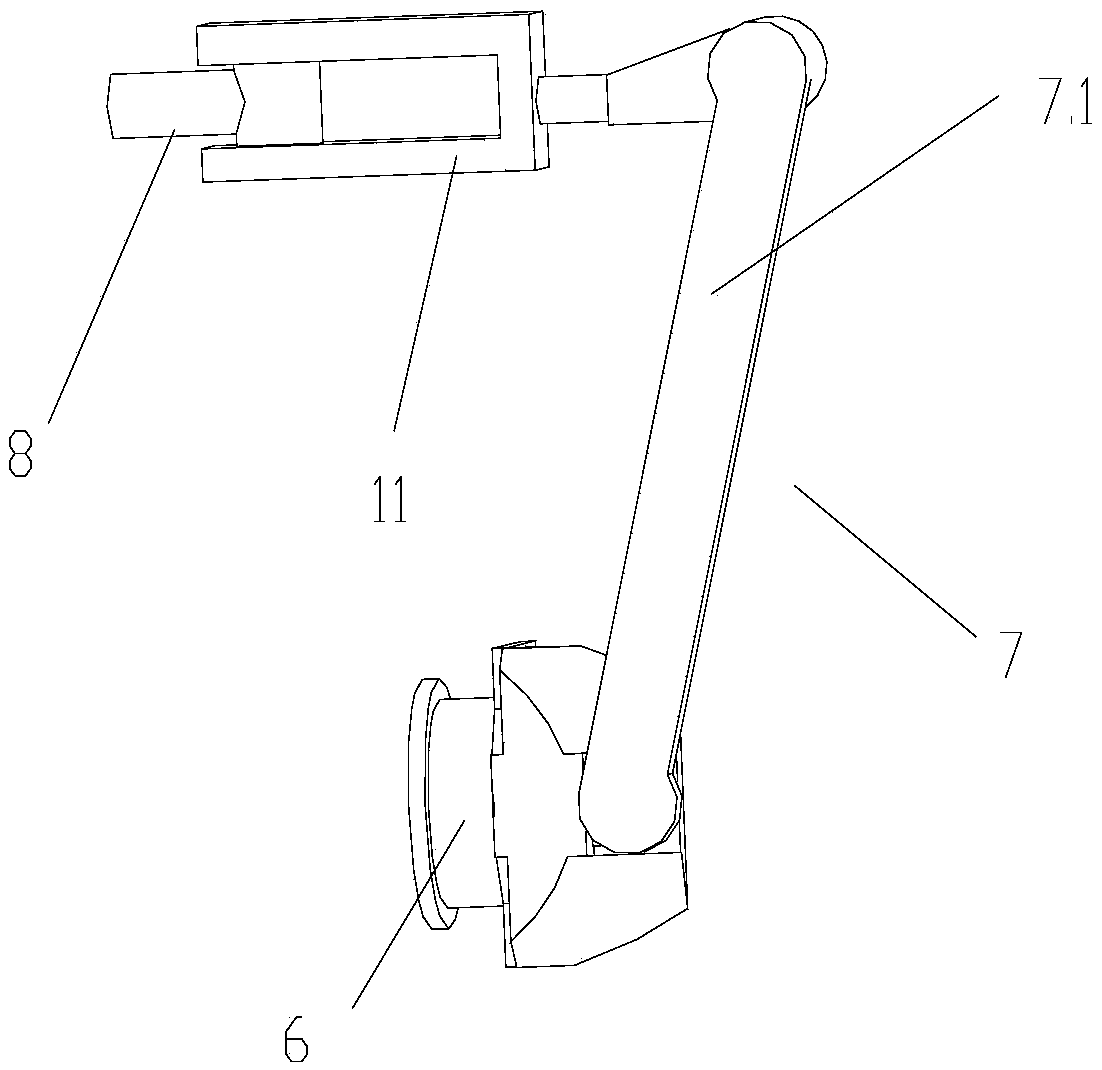

[0023] Such as figure 1 and figure 2 The automatic transformation device for the lining of buried oil tanks shown in , includes a mounting bracket 1 set on the foundation and several connecting rods 2 suspended below the mounting bracket 1, and the bottom of several connecting rods 2 penetrates into the foundation and is embedded in the foundation. In the lower oil tank 3, the bottom of the connecting rod 2 is provided with a track transmission shaft 4 arranged parallel to the central axis of the oil tank 3, and a horizontal slide table 5 that can move along its axial direction is installed on the track transmission shaft 4. 5 is provided with a swivel head 6, and the middle part of the swivel head 6 is provided with an installation through hole, which can be worn on the track transmission shaft 4 and fixed with the installation side of the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com