EVA two-color foam molding machine and medium-mold translation device thereof

A foam molding machine and translation device technology, applied in the field of rubber and plastic processing equipment, can solve the problems of high hardness and wear resistance, high driving pressure of the mold transfer cylinder, and inability to perform mold clamping operations, etc., to achieve hardness and durability. The effect of low grinding performance requirements, long service life and small frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing:

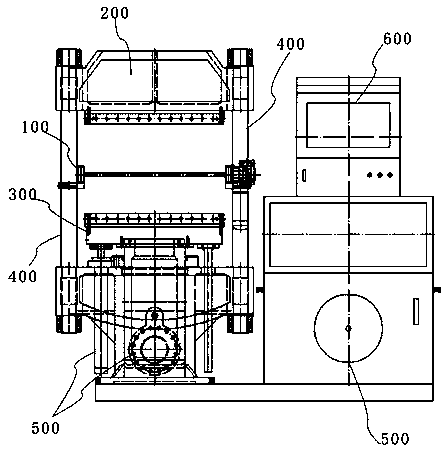

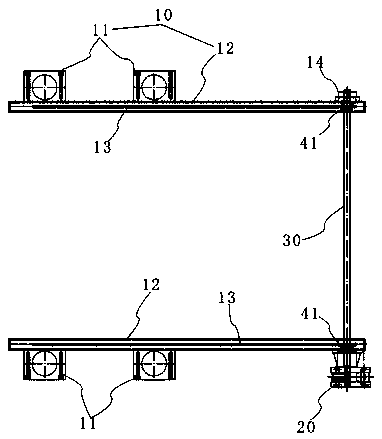

[0031] Such as Figure 1-8 As shown, the present embodiment provides an EVA two-color foam molding machine, including an electric control system 600, a hydraulic system 500, a guide post 400, an upper mold base 200, a lower mold base 300, and a middle mold translation device 100. The hydraulic system 500 includes a main oil cylinder and a small oil cylinder, the upper mold base 200 is fixedly fitted on the top of the guide column 400, and the lower mold base 300 is fixedly arranged at the end of the piston rod of the main oil cylinder and the small oil cylinder and corresponds to the upper mold base 200 up and down , the middle mold translation device 100 is arranged between the upper mold base 200 and the lower mold base 300 so that it can move horizontally back and forth.

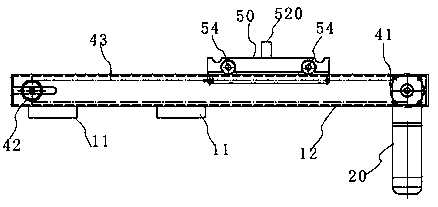

[0032] In this embodiment, the middle mold translation device 100 includes a sliding form frame 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com