Yarn finishing equipment

A yarn and equipment technology, applied in the field of yarn finishing equipment, can solve the problems of lack of counting function, insufficient flexibility, error-prone memory, etc., achieve good connection and power transmission effects, ensure work efficiency, and increase contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

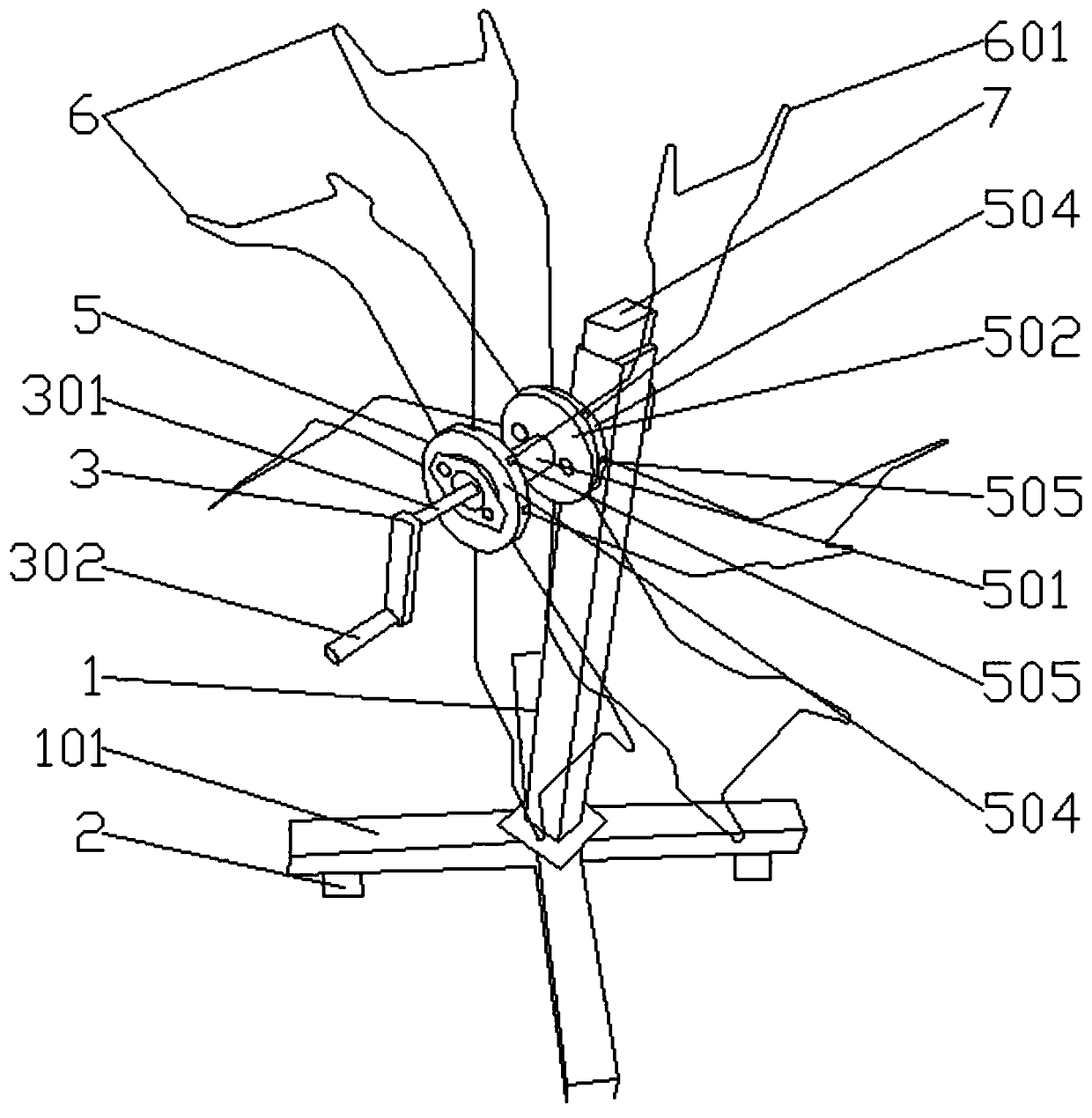

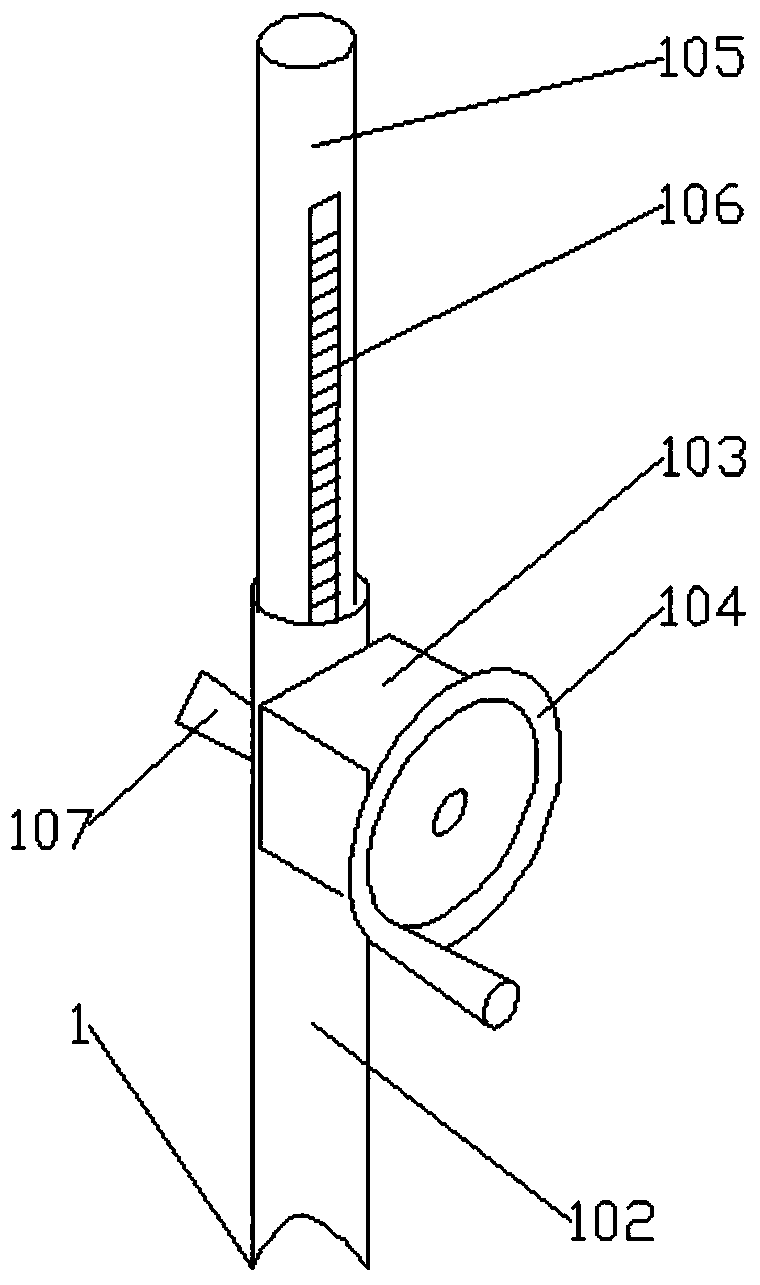

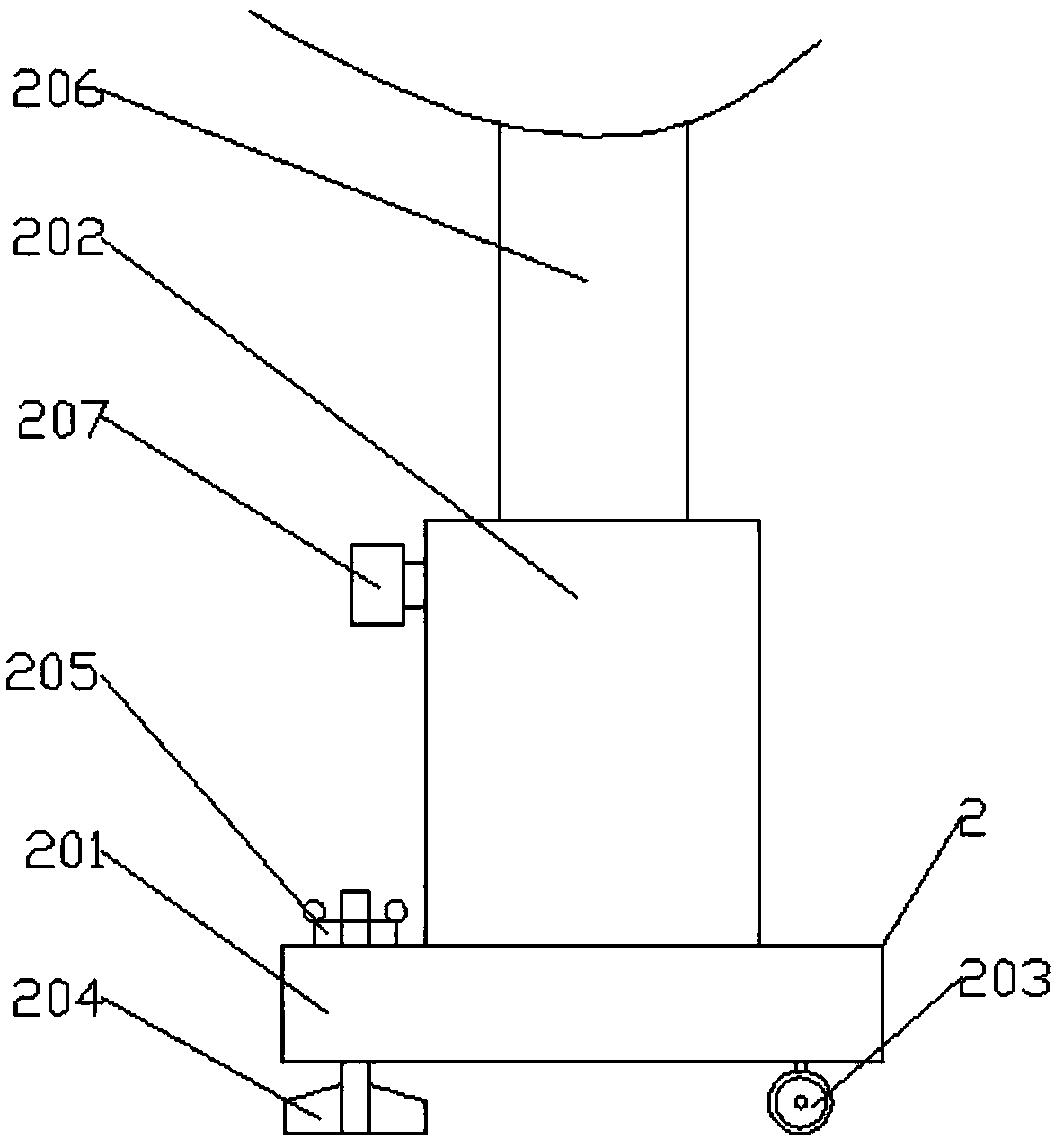

[0046] Such as figure 1 , figure 2 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 with Figure 15The yarn finishing equipment shown includes a lifting frame 1, a rotating mechanism 3 arranged on the upper part of the lifting frame, a connecting piece 4 arranged on the rotating mechanism, a wheel assembly 5 arranged on the rotating mechanism, and a wheel assembly arranged on the rotating mechanism. Several shelving components 6 and the mechanical counting mechanism 7 arranged on the top of the lifting bracket, the connectors are connected with the mechanical counting mechanism; the lifting bracket includes a base 101 and a support cylinder 102 arranged on the base, and the support cylinder is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com