Matchstick processing device

A processing device and match technology, applied in matches, wood processing equipment, manufacturing tools, etc., can solve the problems of difficult slicing processing, waste of manpower, and many equipments, and achieve the effects of lightening cumbersomeness, convenient operation, and reducing manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

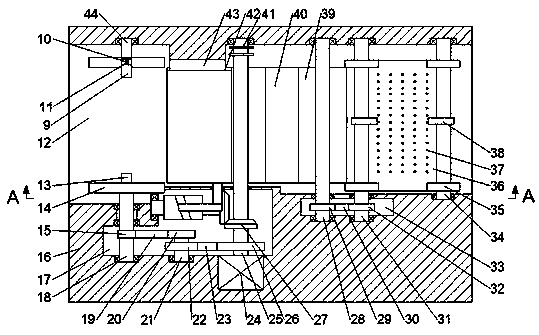

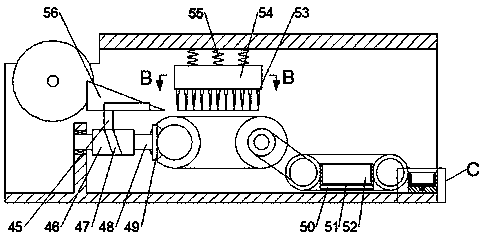

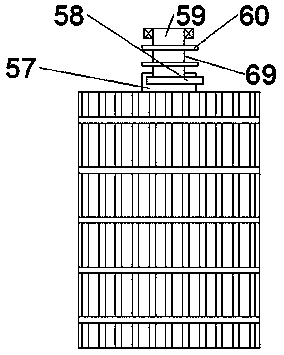

[0016] Combine below Figure 1-4 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0017] refer to Figure 1-4 , according to an embodiment of the present invention, a match processing device includes a device case 16, an acceleration chamber 17 is arranged in the device case 16, and an acceleration mechanism therein, and an acceleration motor 24 in the acceleration mechanism Drive the low-speed lever 25 to rotate, and increase the rotating speed of the high-speed lever 18 through the gear ratio between the medium-speed lever 21 and the high-speed lever 18, so that the wood can be cut into wood chips by the cutting mechanism, and the acceleration motor 24 transmits power to the cutting Mechanism, through the rotation of the moving cylinder 46 in it, drives the moving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com