Micropore pile with inner-wall supporting structure

A support structure and micro-porous technology, which is applied in infrastructure engineering, sheet pile walls, buildings, etc., can solve the problems of unstable support of micro-porous piles, and the lack of support and bearing effect of micro-porous piles, so as to improve the service life. , to prevent position deviation, the effect of reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means realized by the present invention; creative features; achieve the purpose and effect easy to understand, the present invention will be further elaborated below in conjunction with specific embodiments.

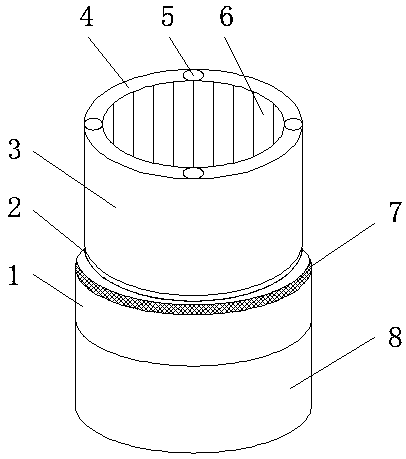

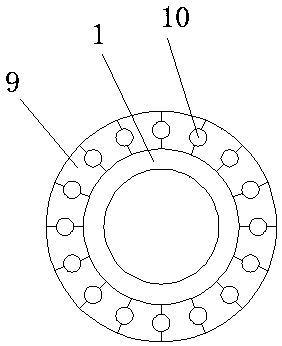

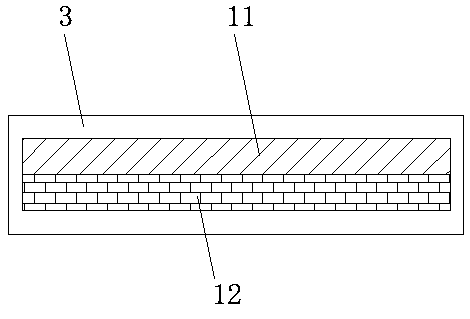

[0018] Such as Figure 1-3 As shown, a microporous pile with an inner wall support structure includes a base 8, the top of the base 8 is fixedly connected with a support bracket 1, and the inside of the support bracket 1 is fixedly connected with a pressure-bearing block 9, and the pressure-bearing A support rod 10 is fixedly connected between the blocks 9, the surface of the support bracket 1 is provided with a protective layer 7, the top of the support bracket 1 has a limiting groove 2, and the top of the supporting bracket 1 is fixed by the limiting groove 2 Connected with a top pile 3, the inside of the top pile 3 is fixedly connected with a steel plate 12, the top of the steel plate 12 is fixedly connected with a concrete layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com