Method for dynamically filling coal mining subsidence area with Yellow River sediment

A technology for filling coal mining and coal mining subsidence, which is applied in the direction of filling, ground mining, mining equipment, etc., can solve the problems of large transportation distance, high economic cost, and large quantities, so as to increase the area of cultivated land, improve economic benefits, and improve The effect of cultivated land rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] A kind of method that utilizes Yellow River silt dynamic filling coal mining subsidence that the inventive method proposes, in conjunction with accompanying drawing and embodiment detailed description is as follows:

[0048] Method of the present invention specifically comprises the steps:

[0049] 1) Predict the maximum subsidence value of mining subsidence and the subsidence value of each stage, including the following steps:

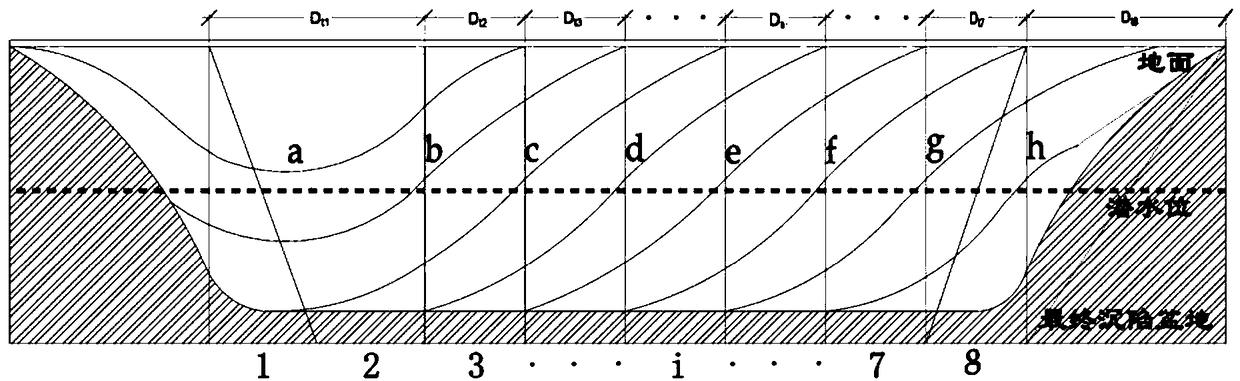

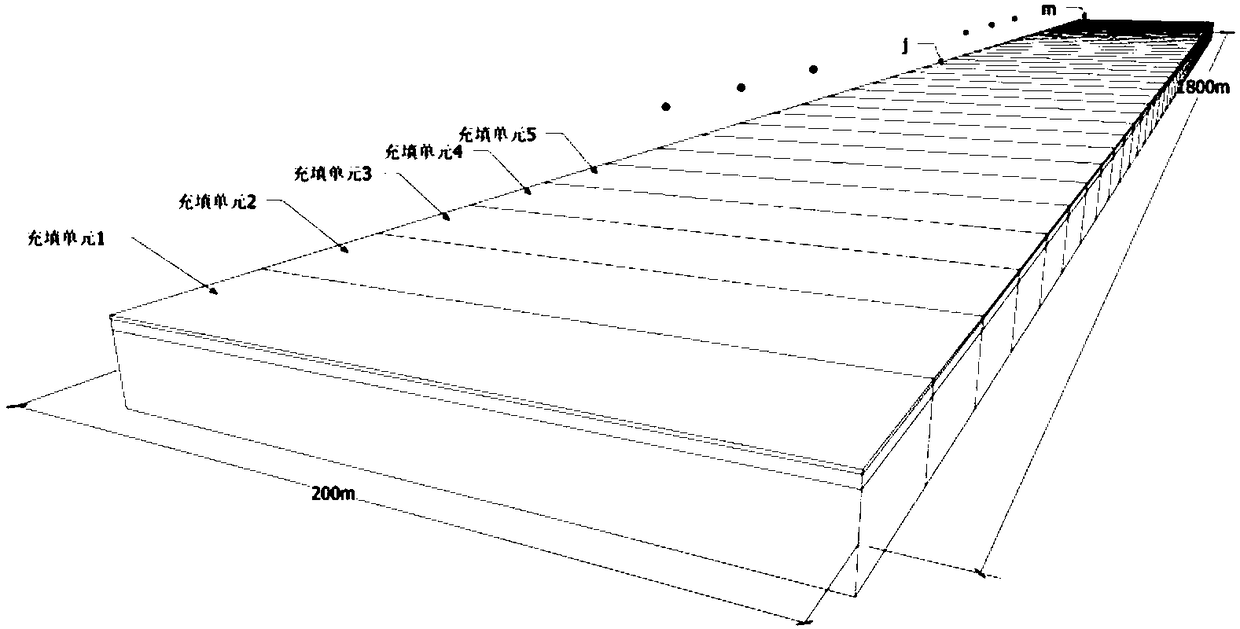

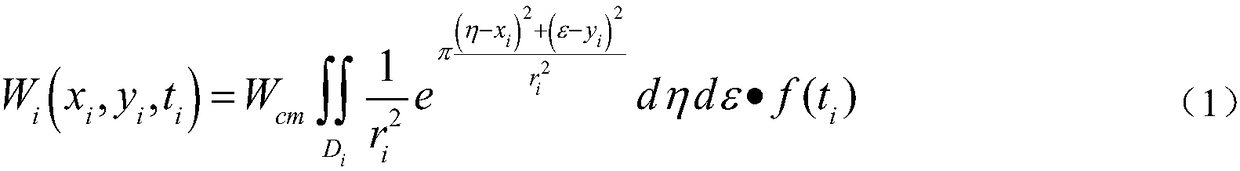

[0050] 1-1) According to the mining plan and the geological conditions of the coal mining subsidence area, select the mining unit and mining time point for each working face. Now take a single working face as an example to illustrate. Since the subsidence values of each point are different, for the convenience of each Filling and reclamation are carried out at different positions of the working face in different periods of time, so the working face is subdivided into several regular rectangular mining units along the mining direction, and eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com