Diesel burner hydraulic air supply and fuel system and using method thereof

A technology of fuel system and air supply system, which is applied in the combustion method, liquid fuel supply/distribution, control of combustion, etc., can solve the problem of poor combustion economy, inability to accurately control and adjust the air supply volume and fuel supply volume of the burner, and inability to Control the exact matching of air supply volume and fuel volume to achieve the effect of high power density, easy electrical control, and ensuring stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

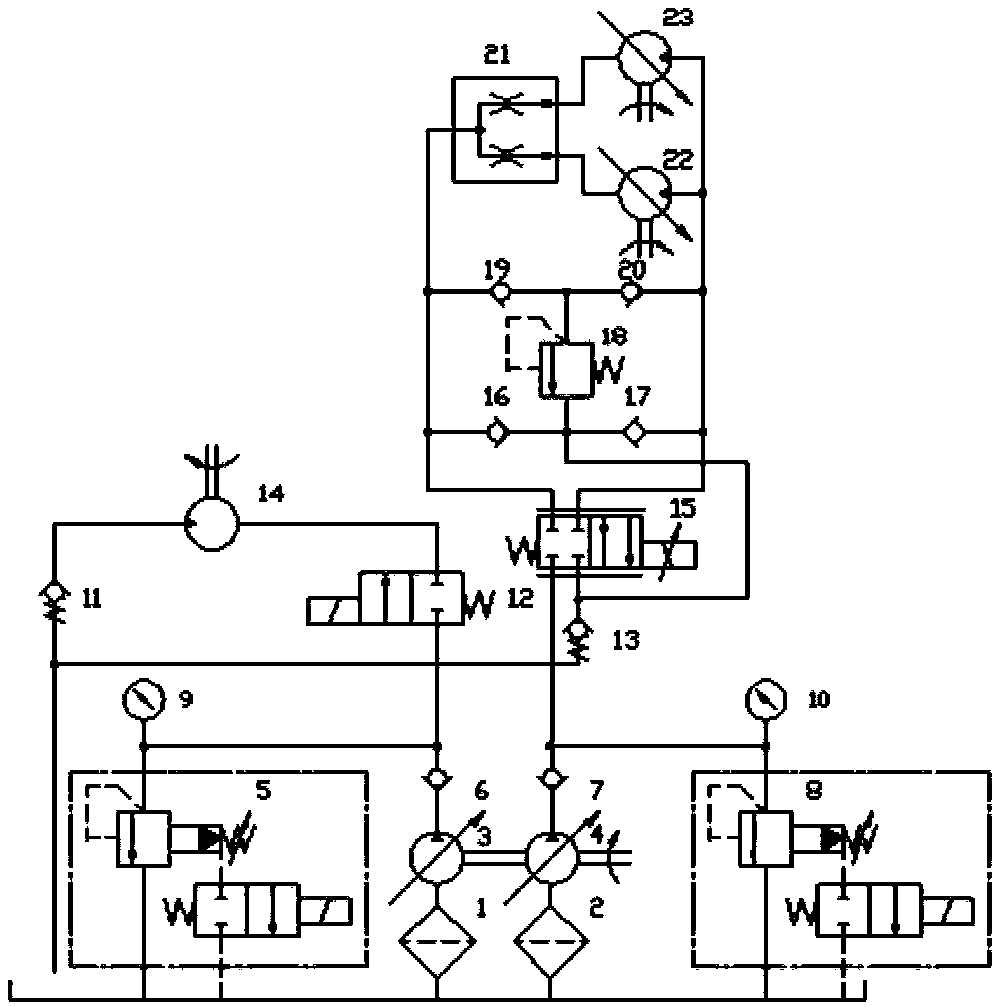

[0034] Such as figure 1 , figure 2As shown, this embodiment provides a hydraulic air supply and fuel system for diesel burners, which is mainly used for air supply and fuel supply in diesel burners, and the ratio of air supply and fuel supply is controlled according to combustion needs . The system mainly includes two subsystems, namely the air supply system and the fuel system; among them, the function of the air supply system is to supply air to the burner, and the function of the fuel system is to inject diesel fuel, diesel fuel and gas into the burner. The mixed combustion generates heat, which is the work of the burner. The structure and working principle of the air supply system and the fuel system will be described in detail below, and on this basis, the use method of the system will be given.

[0035] Such as figure 1 As shown, the air supply system includes an air supply and oil supply part, a first proportional reversing valve 15 and a fan motor. Among them, th...

Embodiment 2

[0049] The hydraulic air supply and fuel system of the diesel burner in Example 1 is used to supply air to the burner through the start of the fan motor. However, during the operation of the fan motor, the oil inlet pressure may exceed its working pressure, so that the fan motor The motor is overloaded, which will affect its life and even cause danger; in addition, at the moment when the first proportional reversing valve 15 cuts off the oil flow, the fan motor is still rotating due to inertia, and the oil supply has been cut off at this time, which will cause Cause hydraulic shock, damage to fan motor, and air supply system. In both cases, there will be adverse effects and need to be effectively avoided. Therefore, this embodiment is optimized on the basis of embodiment 1, and a safety protection circuit and a brake oil supply circuit are added to the air supply system to avoid the occurrence of the above two situations.

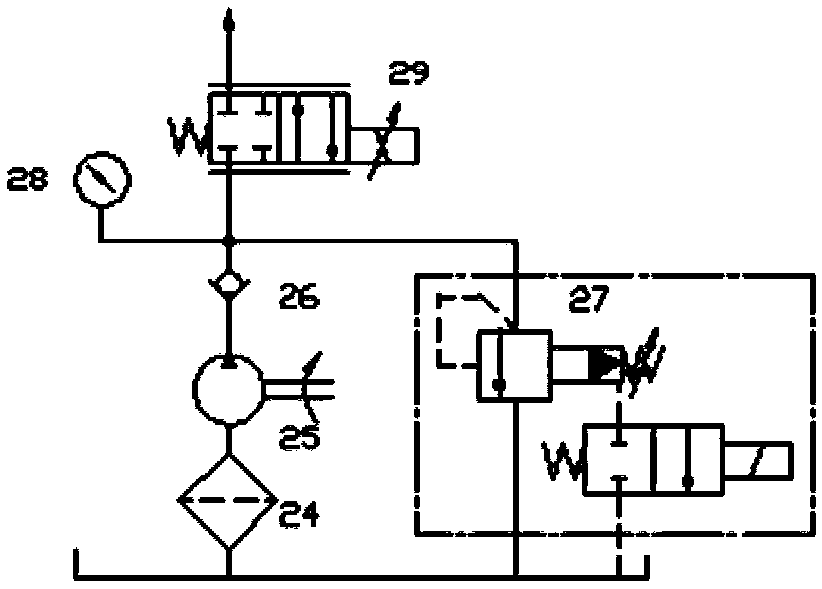

[0050]Specifically, the brake oil supply circuit inc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap