Pyrometer

A pyrometer and main body technology, applied in the field of temperature measurement, can solve the problems of inability to eliminate visible light interference, inconvenient installation, easy damage, etc., and achieve the effects of improving data reliability, maintaining stability, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0030] It should be noted that the structures, proportions, sizes, etc. shown in the drawings attached to this specification are only used to match the content disclosed in the specification, for those who are familiar with this technology to understand and read, and are not used to limit the implementation of the present invention Any modification of the structure, change of the proportional relationship or adjustment of the size shall still fall within the scope of the technical content disclosed in the present invention without affecting the effect and purpose of the present invention. In the range.

[0031] At the same time, terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in this specification are only for the purpose of description, and are not used to limit the present invention. The practicable scope, the change or adjustment of its relative relationship, without any substantial change in the technical content, shall also be regarded as the pr...

Embodiment 1

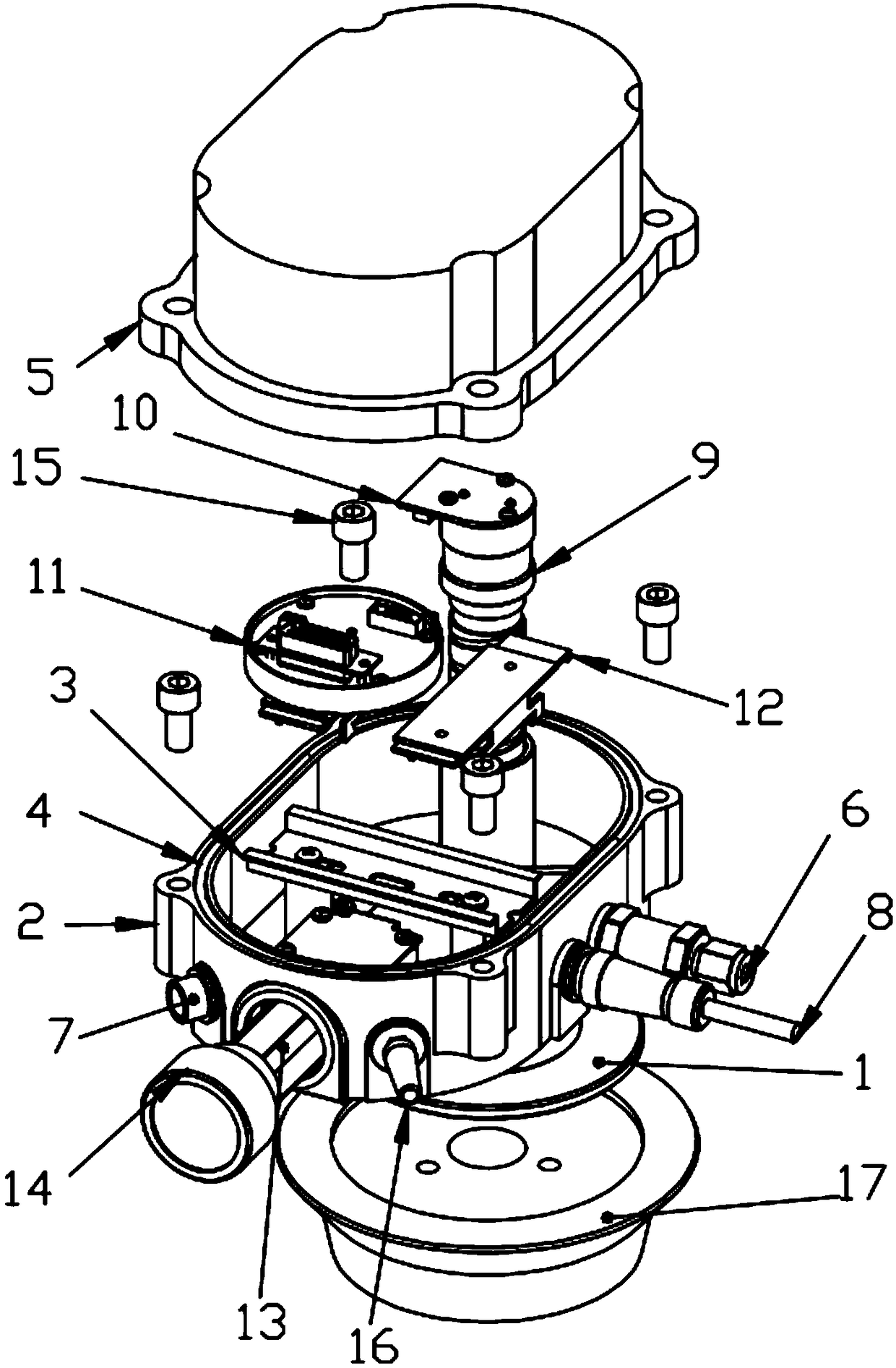

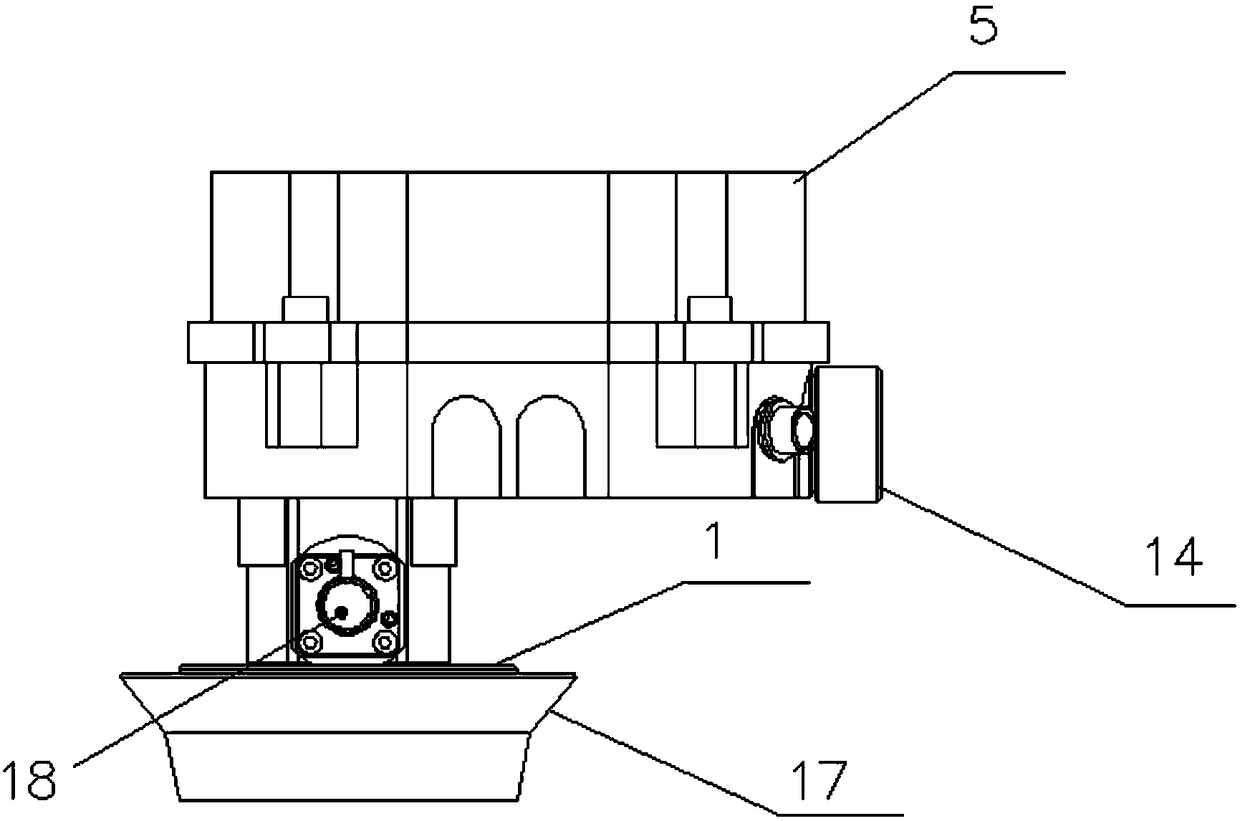

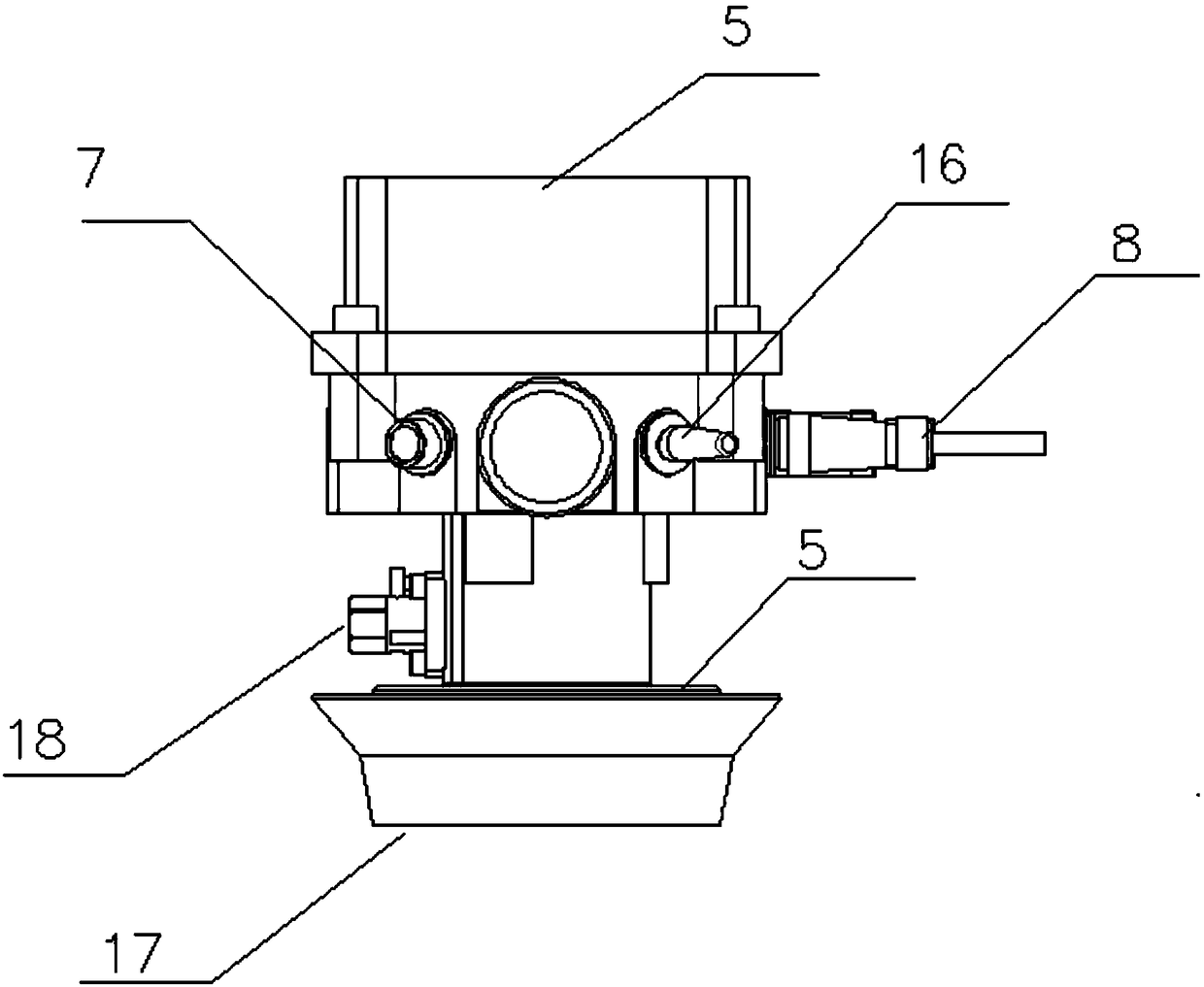

[0033] Such as figure 1 As shown, a pyrometer includes a main body 2 and an upper cover 5 connected together, and the edges where the main body 2 and the upper cover 5 are in contact are provided with lugs for screws 15 to pass through, that is, the main body 2 and the upper cover 5 are connected by bolts;

[0034] The main body 2 is equipped with an electrical guide rail 3, and the electrical guide rail 3 is provided with a conversion module 11 and an expansion board 12; the electrical guide rail 3 adopts a DN35 guide rail, and the use of guide rails is an installation method for industrial electrical components, and the installation supports this standard The electrical components can be easily clamped on the guide rail without fixing with screws, and the maintenance is also very convenient. The expansion board 12 is reserved for installing various conversion modules. For example, when a battery is used, a battery management module can also be installed on the expansion boa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com