Multi-optical-axis consistency detecting device and method based on target switching

A detection equipment and multi-optical axis technology, which is applied in the direction of optical instrument testing, optical performance testing, machine/structural component testing, etc., can solve the problems of insufficient precision, poor versatility, complicated debugging and maintenance operations, etc., and achieve simple calibration, The effect of high precision and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

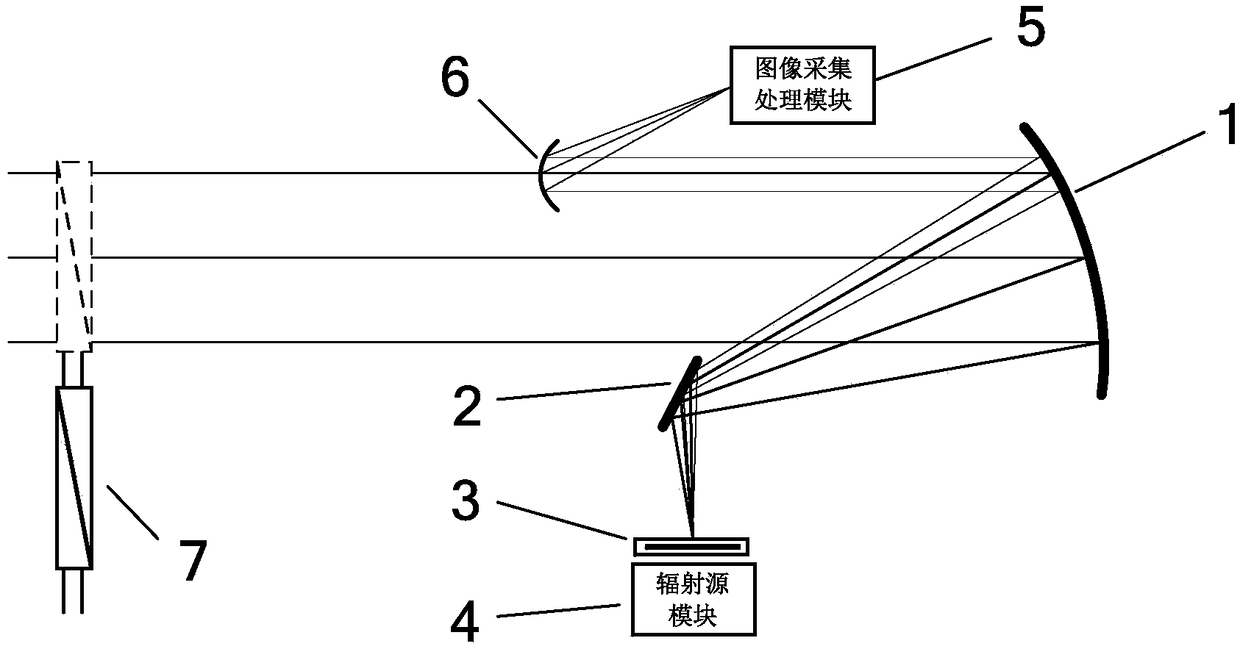

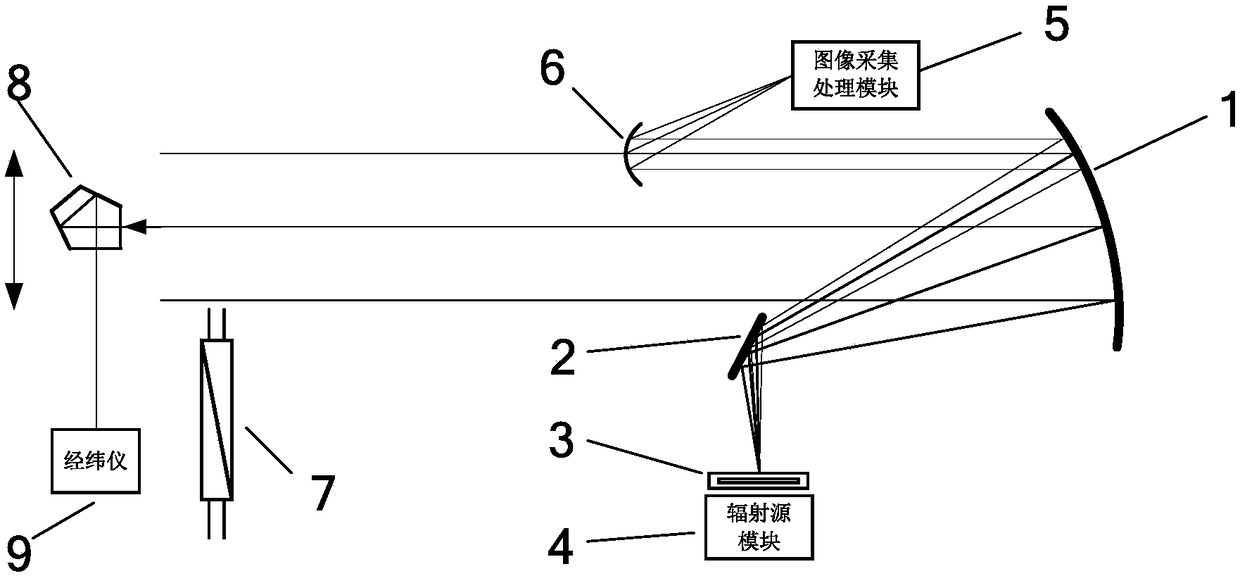

[0022] A multi-optical axis consistency detection device based on target switching, using the target switching method to realize the deviation test between infrared (TV), laser emission and laser reception, etc. Mirror 2, target module 3, radiation module 4, image acquisition and processing module 5, off-axis small parabolic mirror 6 and double wedge assembly 7, off-axis parabolic mirror 1, deflection mirror 2, target module 3, radiation Source module 4, image acquisition and processing module 5, off-axis small parabolic mirror, and double wedge assembly 7; wherein off-axis parabolic mirror 1, deflection mirror 2, target assembly 3 and radiation source module 4 constitute the infrared analog light of the equipment axis; off-axis parabolic mirror 1, deflection mirror 2, target module 3, off-axis small parabolic mirror 6 and image acquisition and processing module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com