Pulley block type vertical shaft lifting joint-adjusting test device and method

A technology of testing device and pulley block, which is applied in the direction of measuring device, machine/structural component testing, instrument, etc., can solve the problem of inability to simulate, lack of loading detection, bearing performance of spindle device, pad anti-skid performance, brake braking performance, etc. Accurately evaluate and other issues to achieve the effect of reducing the bore, improving economy, and reducing the diameter of the pulley

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

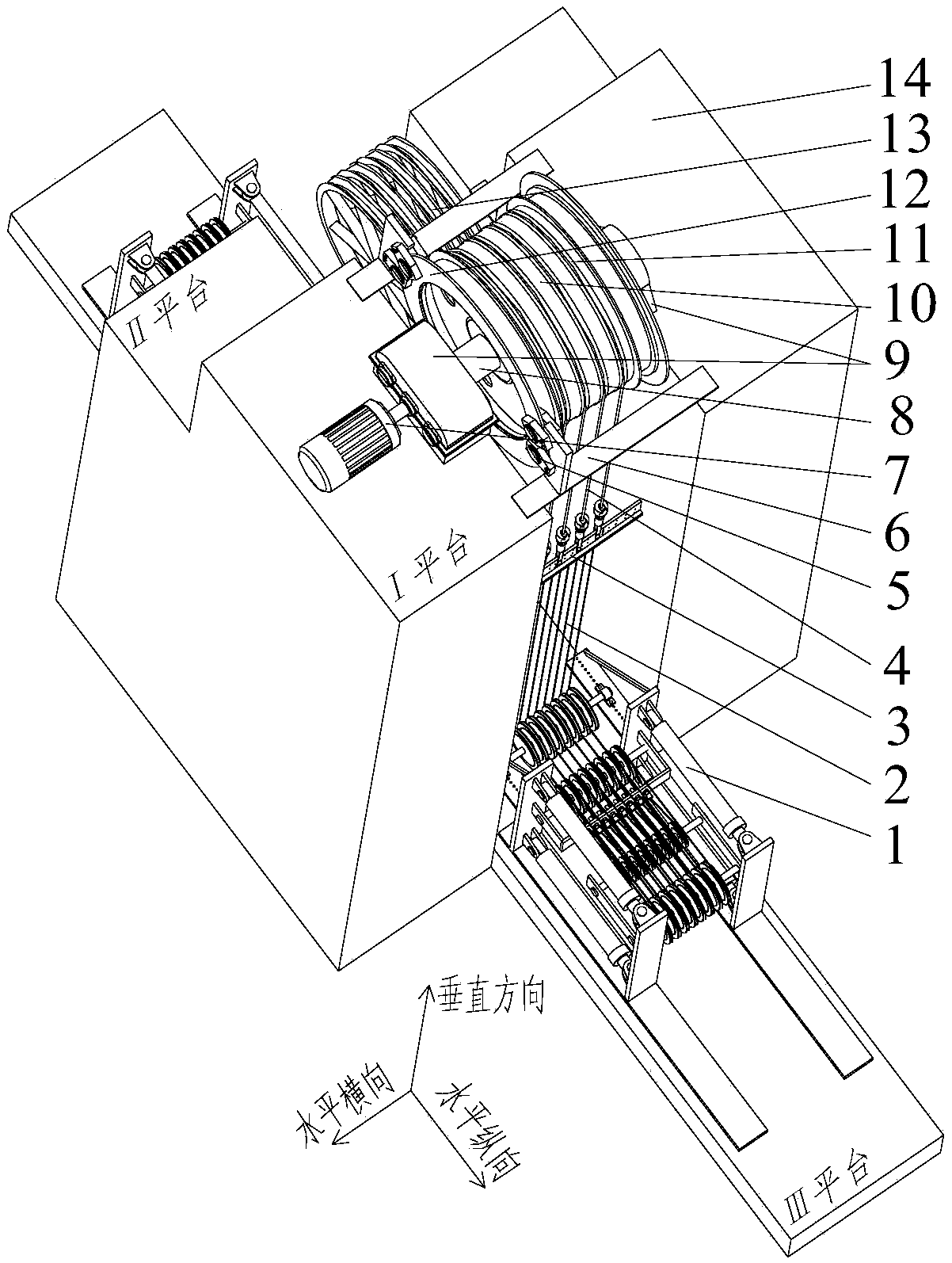

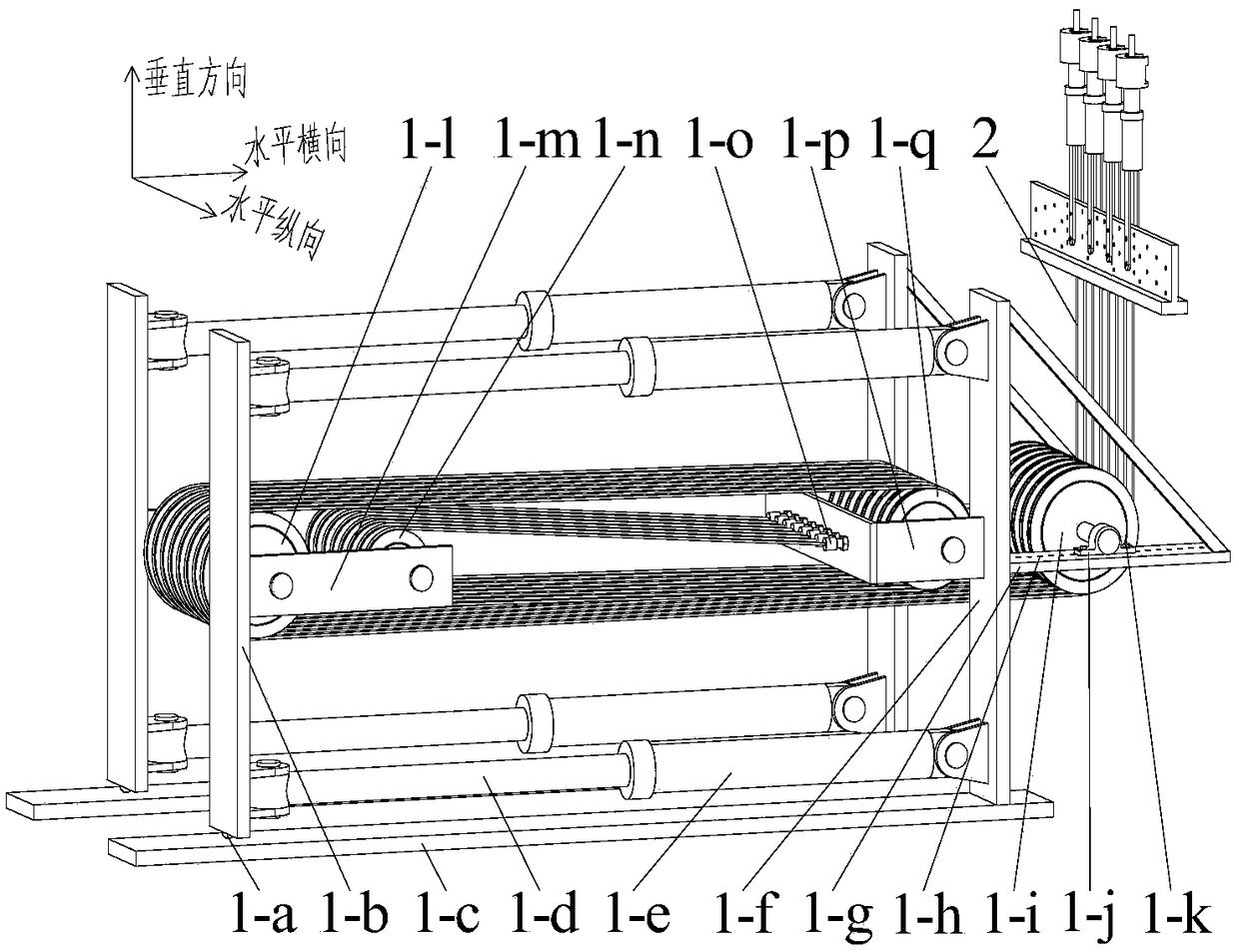

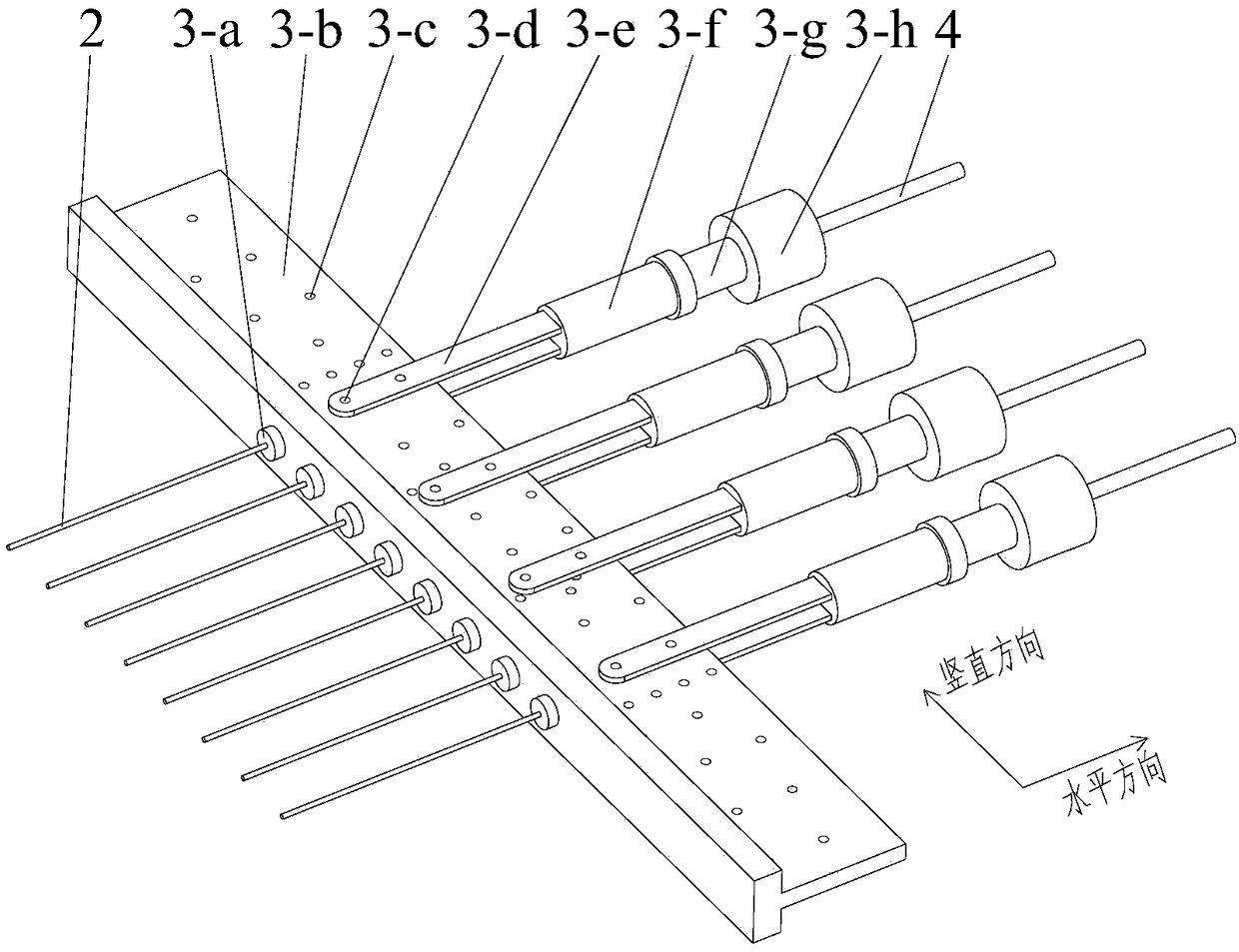

[0040] Such as figure 1 As shown, a pulley block type vertical shaft hoisting joint debugging test device includes a support base 14, a pulley block loading device 1, a pulley rope 2 and a rope pitch positioning device 3, and the support base 14 is in the shape of a groove along the horizontal direction, and along the horizontal direction It is in the shape of steps in the longitudinal direction, and forms I platform, II platform, and III platform according to different heights; on the III platform of the support foundation 14, there are two pulley block loading devices 1 arranged horizontally and longitudinally symmetrically; The main shaft device of the vertical shaft hoist to be measured is installed astride the motor 7, the bearing seat 9, the main shaft 8, the reel 10, the brake disc 12, the friction lining 11, the brake support plate 6, and the brake ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com