Thermodynamic modeling and thermal design method of high speed machine tool structure

A technology of thermodynamic modeling and processing machine tools, applied in computer-aided design, design optimization/simulation, CAD numerical modeling, etc., can solve problems that cannot meet the design requirements of high-speed processing machine tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] The method for designing the structure thermodynamics of the high-speed machining machine tool according to the present invention will be further described in detail below in conjunction with an embodiment (precision numerical control internal circular compound grinding machine).

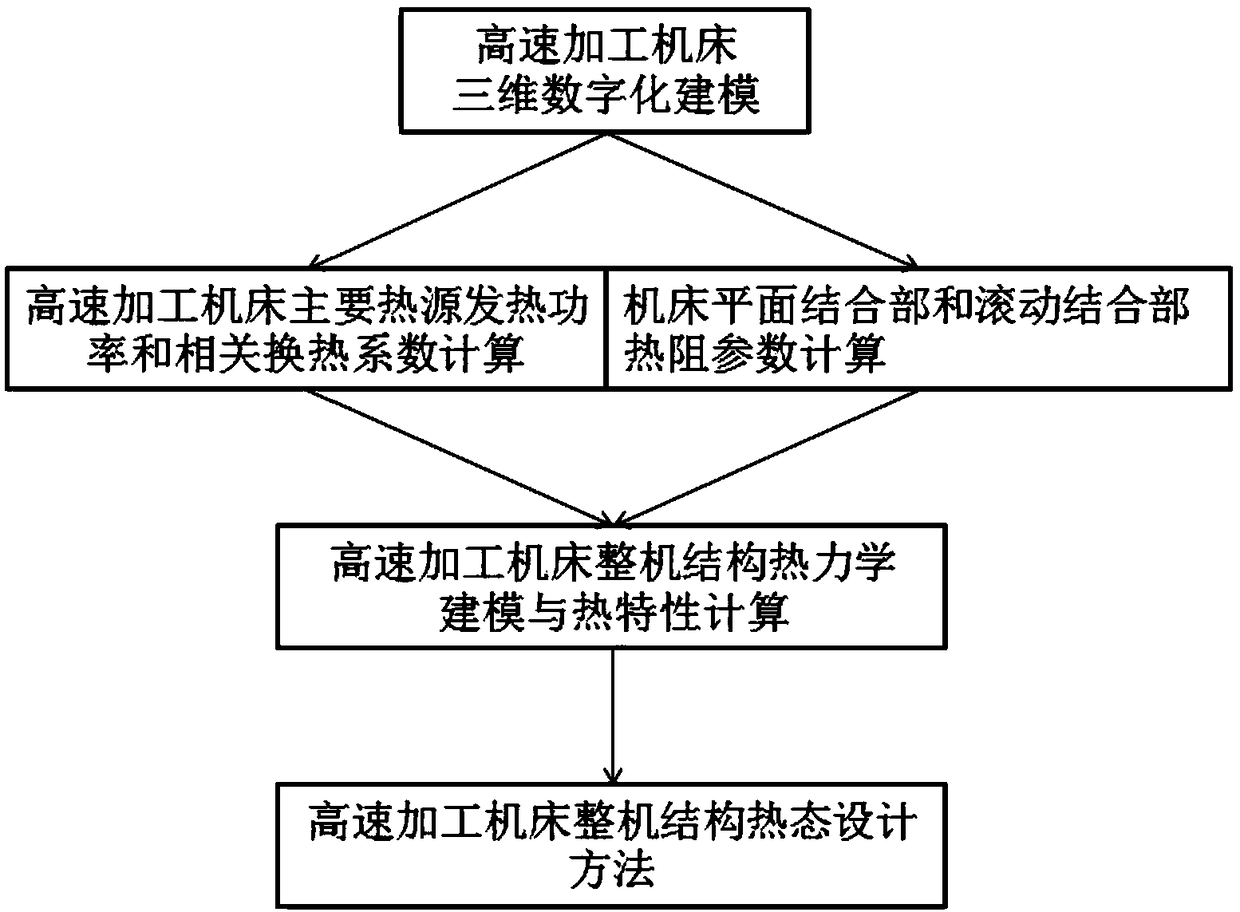

[0087] figure 1 The specific content of the high-speed machining machine tool structure thermodynamic design method of the present invention is given, including the following steps: Step 1: three-dimensional digital modeling of the high-speed machining machine tool

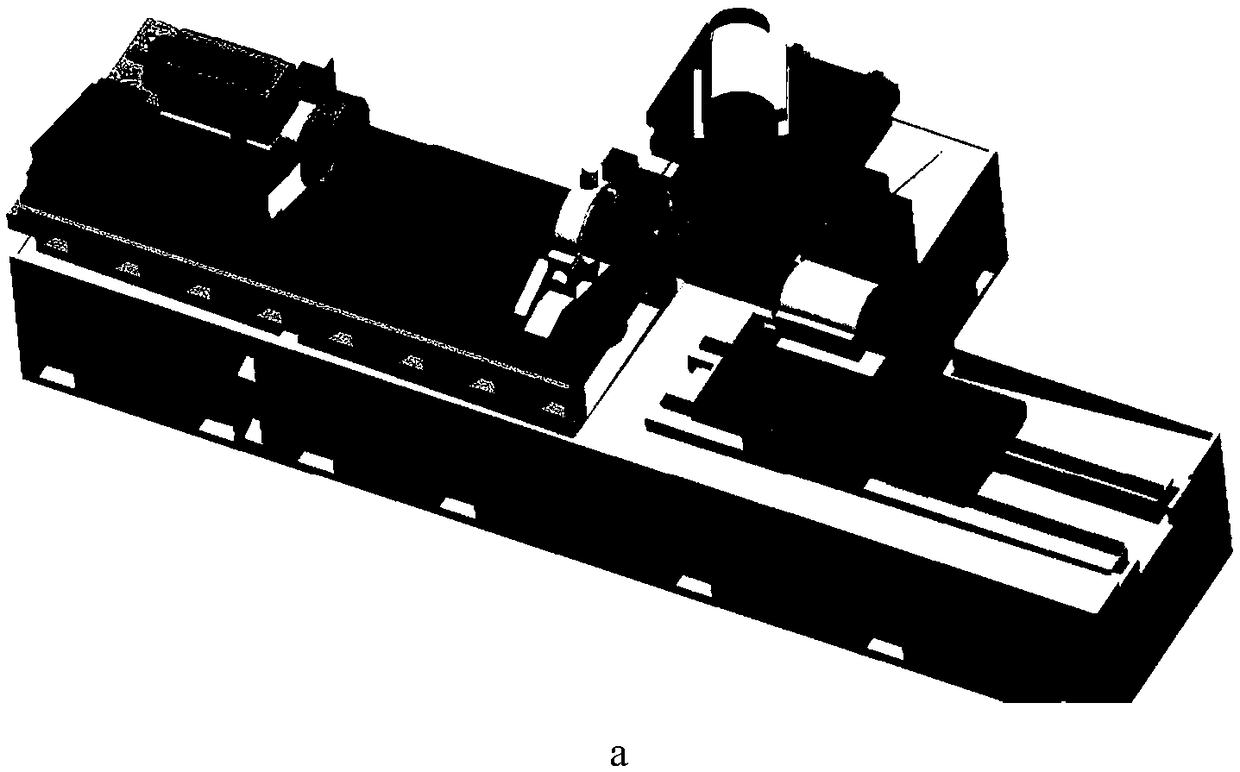

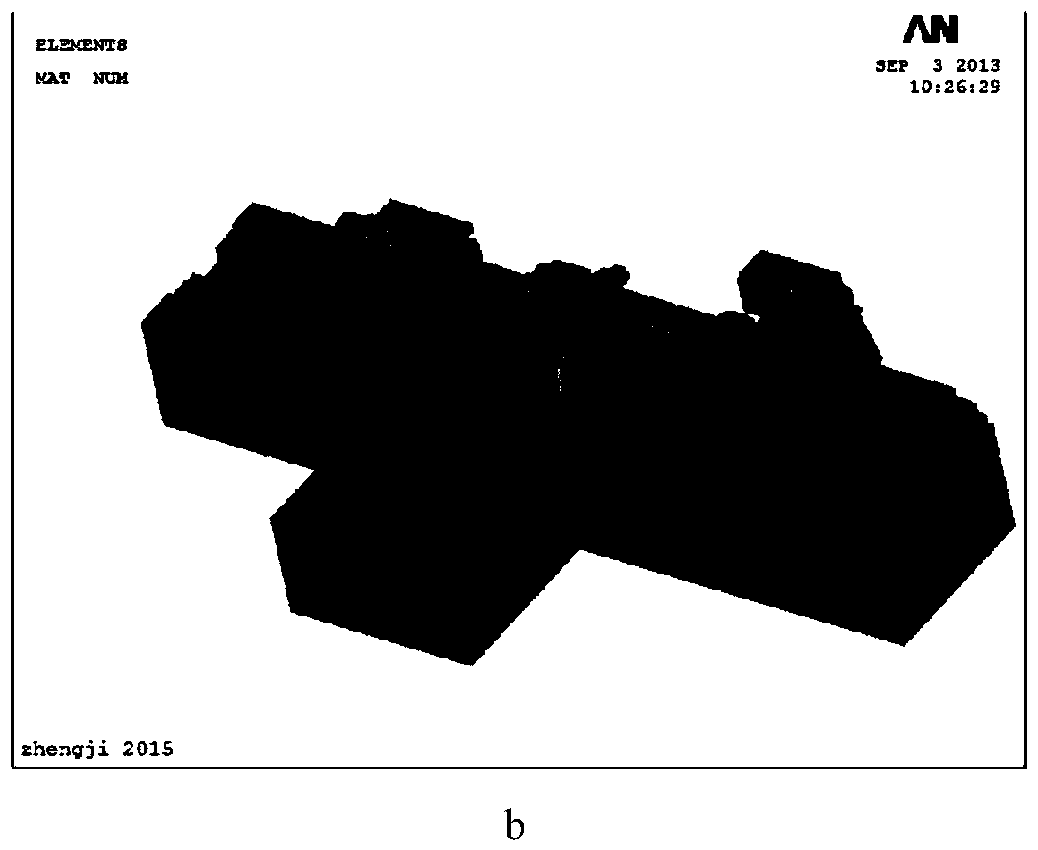

[0088] Use 3D modeling software (such as Solidworks) to establish a 3D digital (CAD, CAE) model of a precision CNC internal cylindrical compound grinding machine, such as figure 2 shown.

[0089] Step 2: Calculation of the heating power of the main heat source of the high-speed machining tool

[0090] Step 2a: Using the formulas (1)-(3), calculate the heating power Q of the rolling bearing of the grinding electric spindle of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com