Horizontal winding taping integrated machine

A horizontal winding machine, integrated machine technology, applied in cable/conductor manufacturing, electrical components, circuits, etc., can solve problems such as increasing the uncontrollability and destructiveness of wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

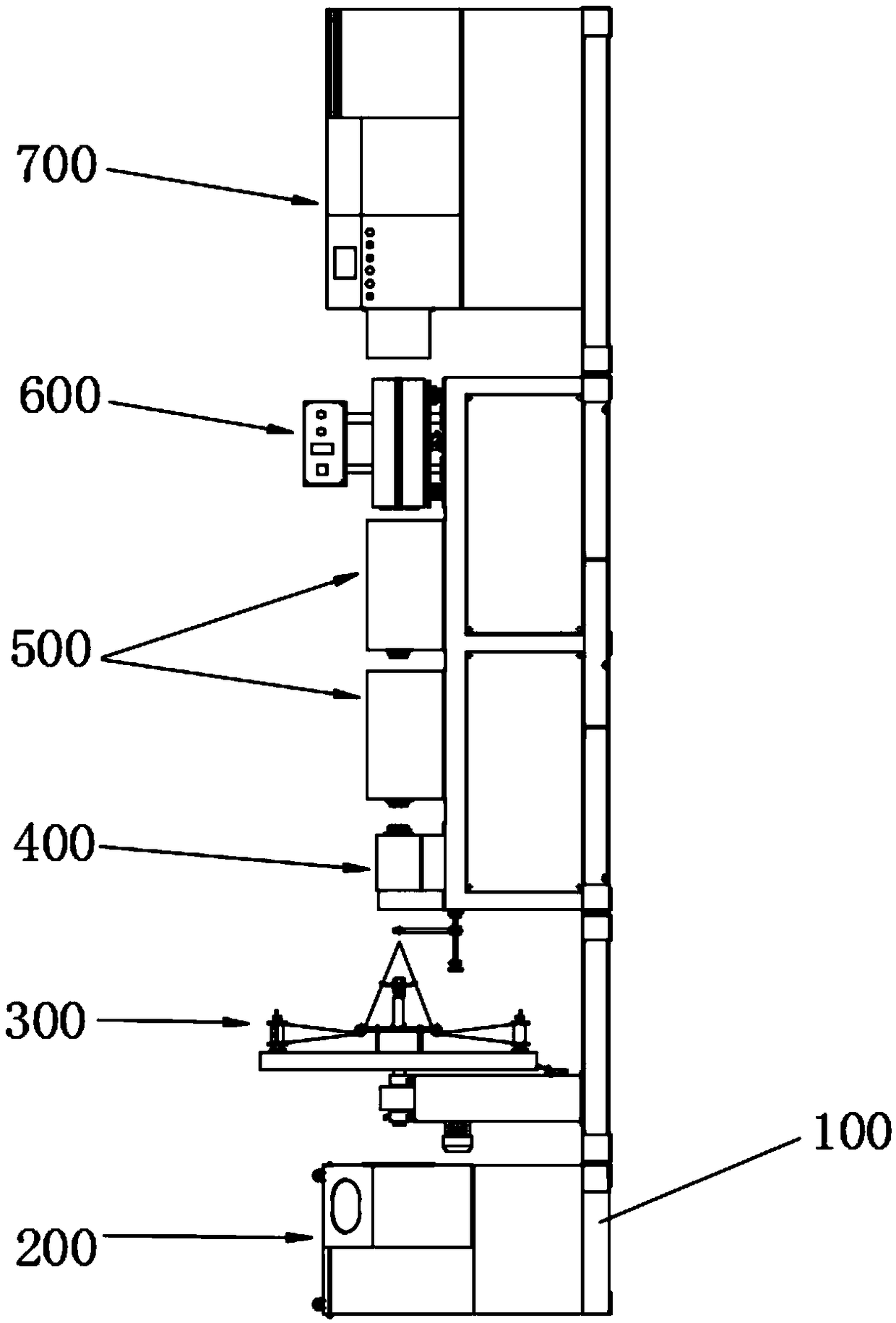

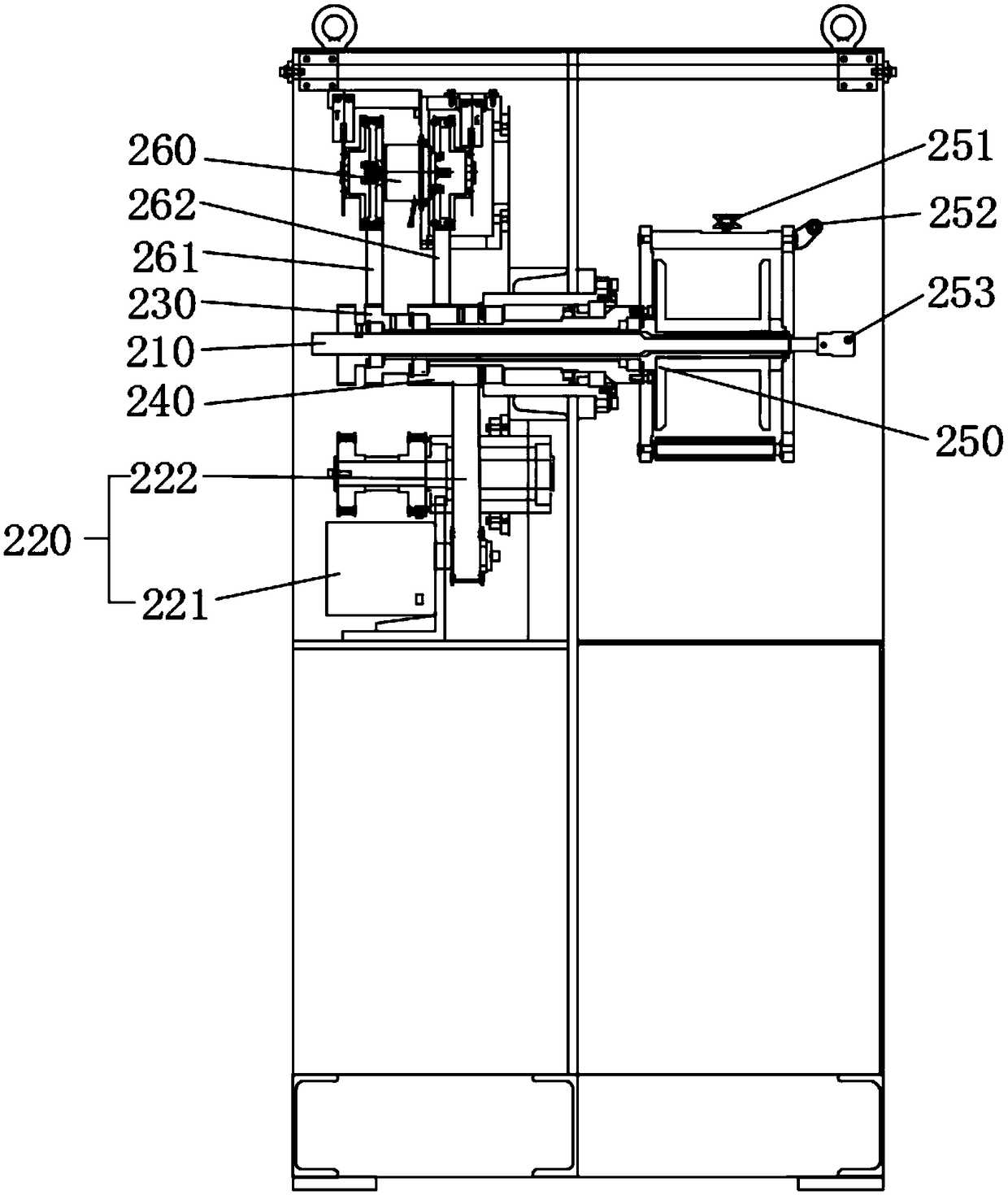

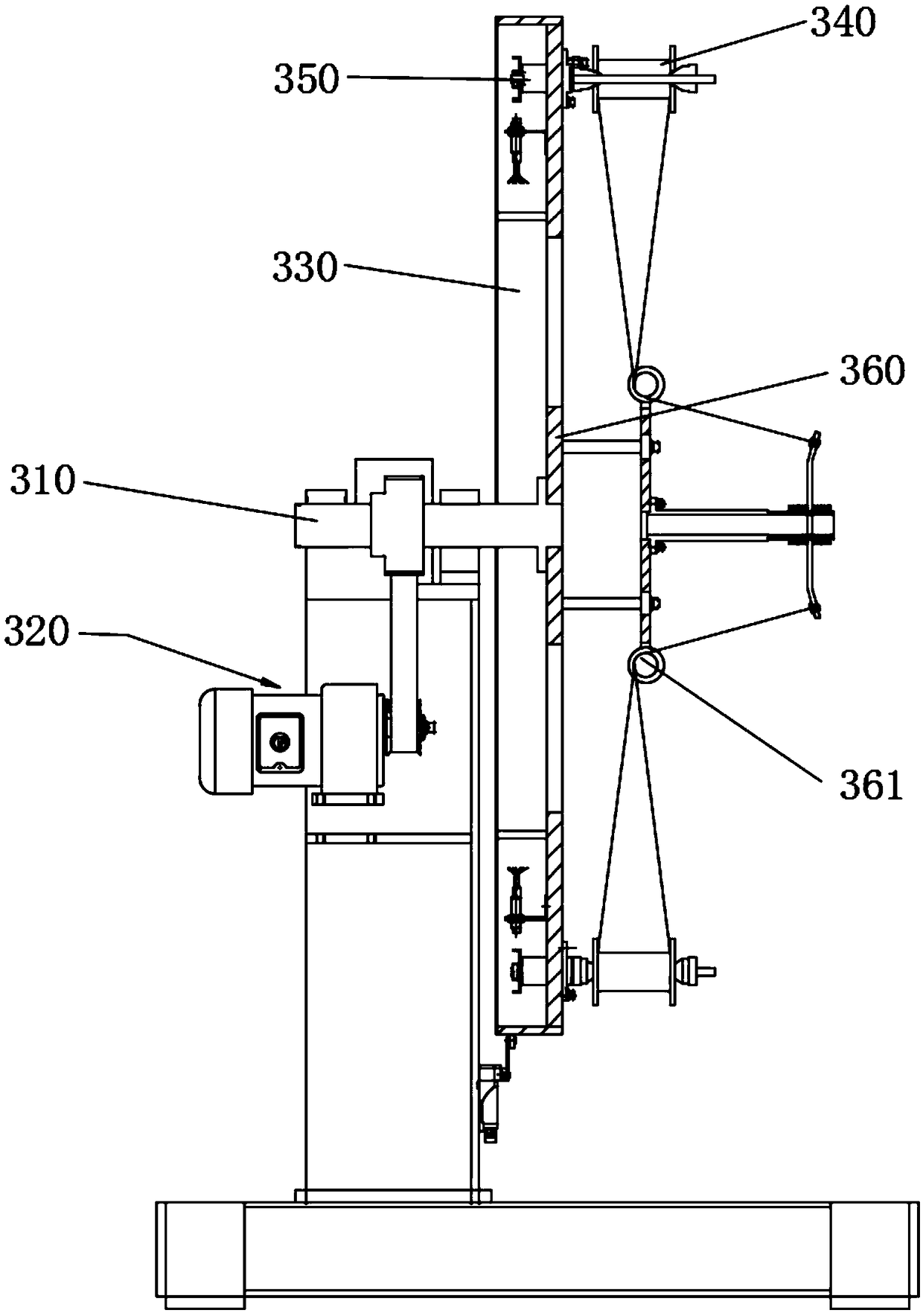

[0026] Such as figure 1 As shown, a horizontal winding and taping integrated machine provided by the present invention includes a machine base 100, and the machine base 100 is sequentially provided with an untwisting machine 200, a horizontal winding machine 300, a pre-twisting machine 400, a double-headed horizontal Type taping machine 500, infrared oven 600 and drawing single stranding machine 700; The untwisting machine 200 is used to carry out the first taping winding to the wire; The horizontal winding machine 300 is used to wind the wire through the untwisting machine The wire rod is used for the second tape winding; the pre-twisting machine 400 is used to rotate the wire rod passing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com