Limit mold for back lapping of infrared focal plane detector and preparation method

An infrared focal plane and detector technology, applied in the direction of manufacturing tools, semiconductor devices, stone processing equipment, etc., can solve the problem that the reserved thickness of the chip cannot be accurately controlled within the deviation range, and the consistency and uniformity of the chip thickness of the module cannot be guaranteed. Complex layer operations and other issues, to avoid uncontrollable operations, ensure consistency and uniformity, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of this patent will be described in detail below by taking a mercury cadmium telluride infrared focal plane device with a photosensitive element array of 32x4 as an example:

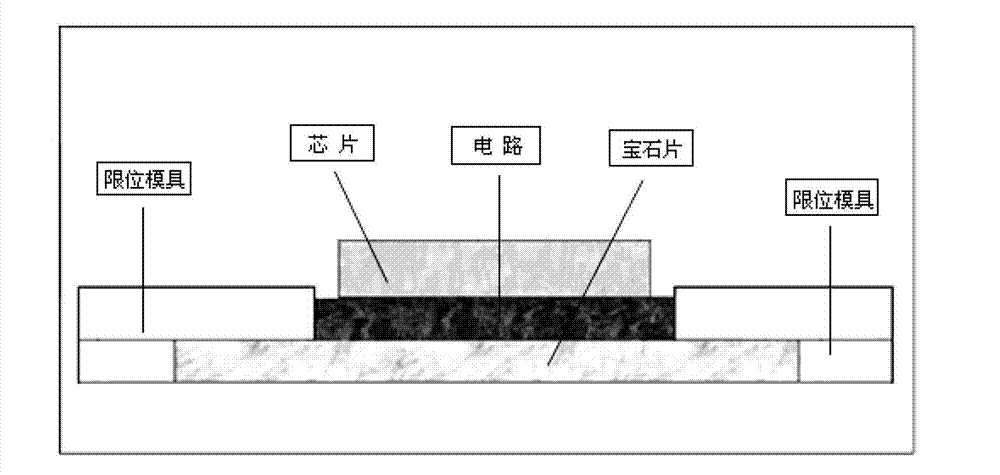

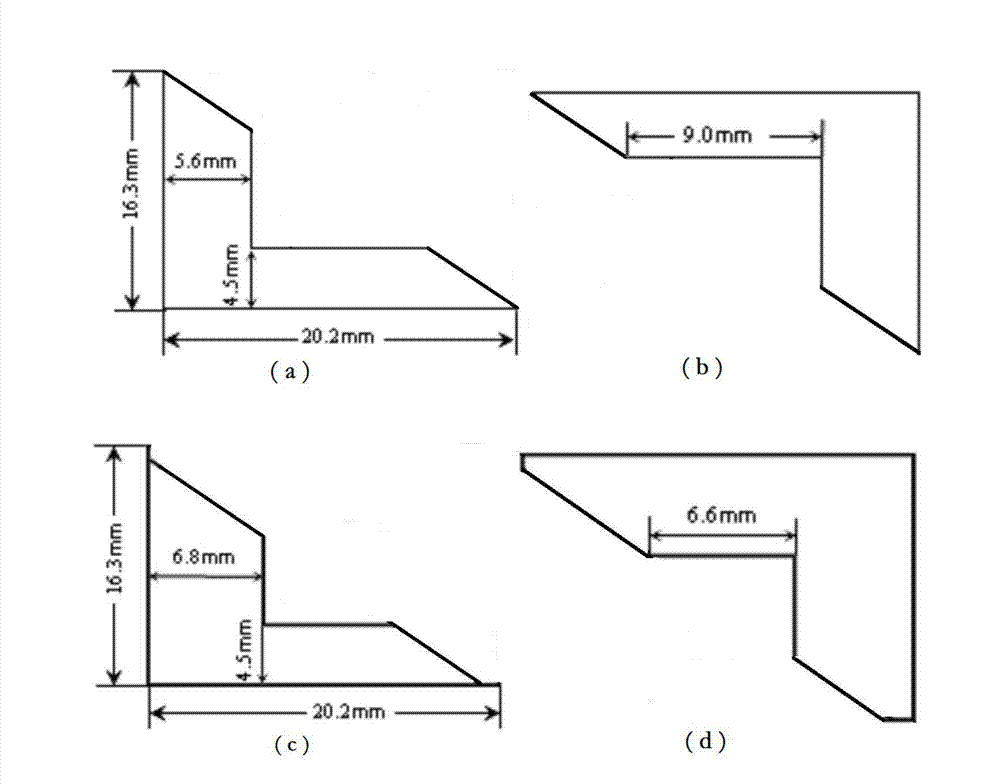

[0029] The upper chip of the 32x4 HgCdTe infrared focal plane device in this example is made of GaAs substrate material, the readout circuit of the middle layer is made of Si-based material, and the substrate material is gemstone. The thickness of the GaAs substrate is 350 μm, the thickness of the intermediate circuit is 450 μm, and the thickness of the lower gemstone substrate is 330 μm. According to the project requirements, the thickness of the final chip reserved is 20 μm.

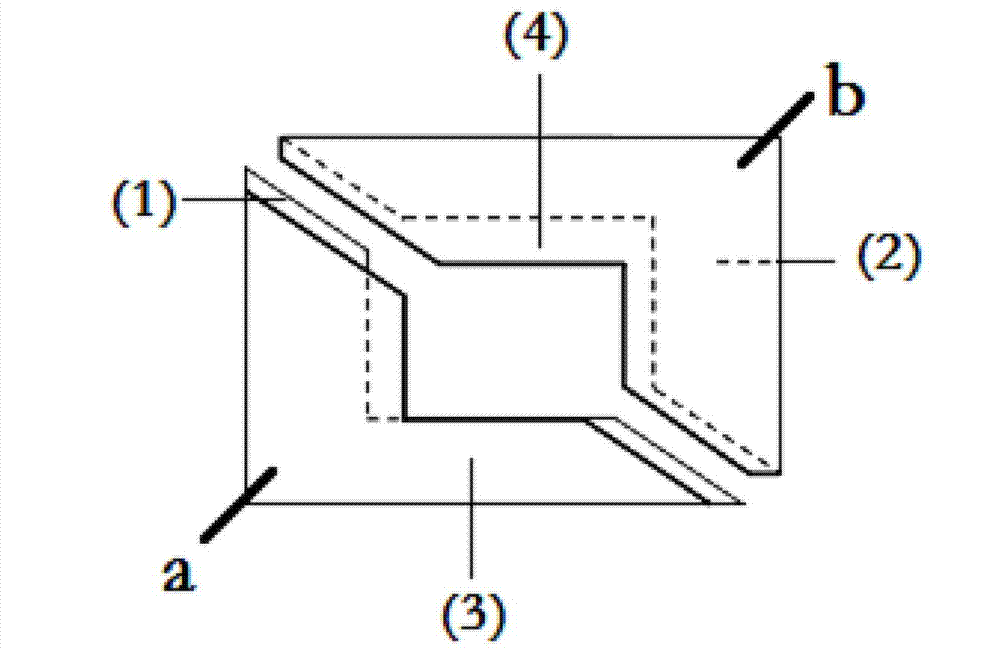

[0030] The method for controlling the thinning thickness of the back of the infrared focal plane detector according to the present invention is used to prepare corresponding limiting molds according to the specific specifications of the 32x4 focal plane module.

[0031] First, choose two rectangular whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com