Automatic heat sleeving assembly machine

A set of automatic technology, applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of the uniform temperature of the difficult workpiece A station, the difficulty of unifying the depth of knocking, and the complexity of personnel management, so as to avoid resources Waste and safety hazards, increased yield and uniformity, improved automation effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail with reference to the accompanying drawings and embodiments. The following embodiments are for explaining the present invention and the present invention is not limited to the following embodiments.

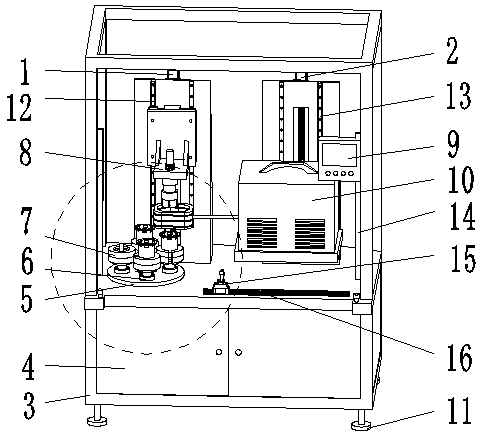

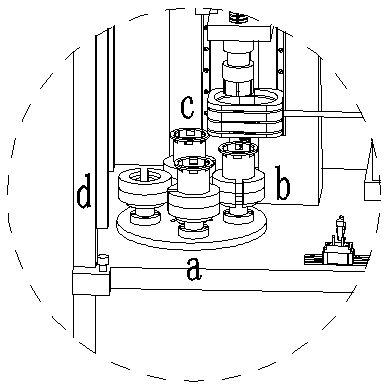

[0022] See figure 1 , This embodiment includes electrical systems, mechanical systems, and PLC control systems. The electrical system includes tooling servo system 1, heating servo system 2 and moving parts control system, and the electrical system is controlled by the PLC control system. The mechanical system includes a rack 3 and a built-in control cabinet 4 installed on the rack, a tooling dividing device, a touch device 9 and a high-frequency induction heating device 10.

[0023] The frame 3 is composed of square tubes and steel plates, and has a firm structure. The bottom of the rack 3 is provided with a leveling foot 11, and the height of the rack 3 can be fine-adjusted by the leveling foot 11 to meet actual usage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com