Integrated receiving device and working method for treating kitchen waste material

A kitchen waste and receiving device technology, applied in the direction of solid waste removal, etc., can solve problems such as unbalanced fluctuations, difficulty in controlling the thickness of the material layer, uneven discharge, etc., achieve a high degree of automation, simple and practical structure, and realize automatic The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

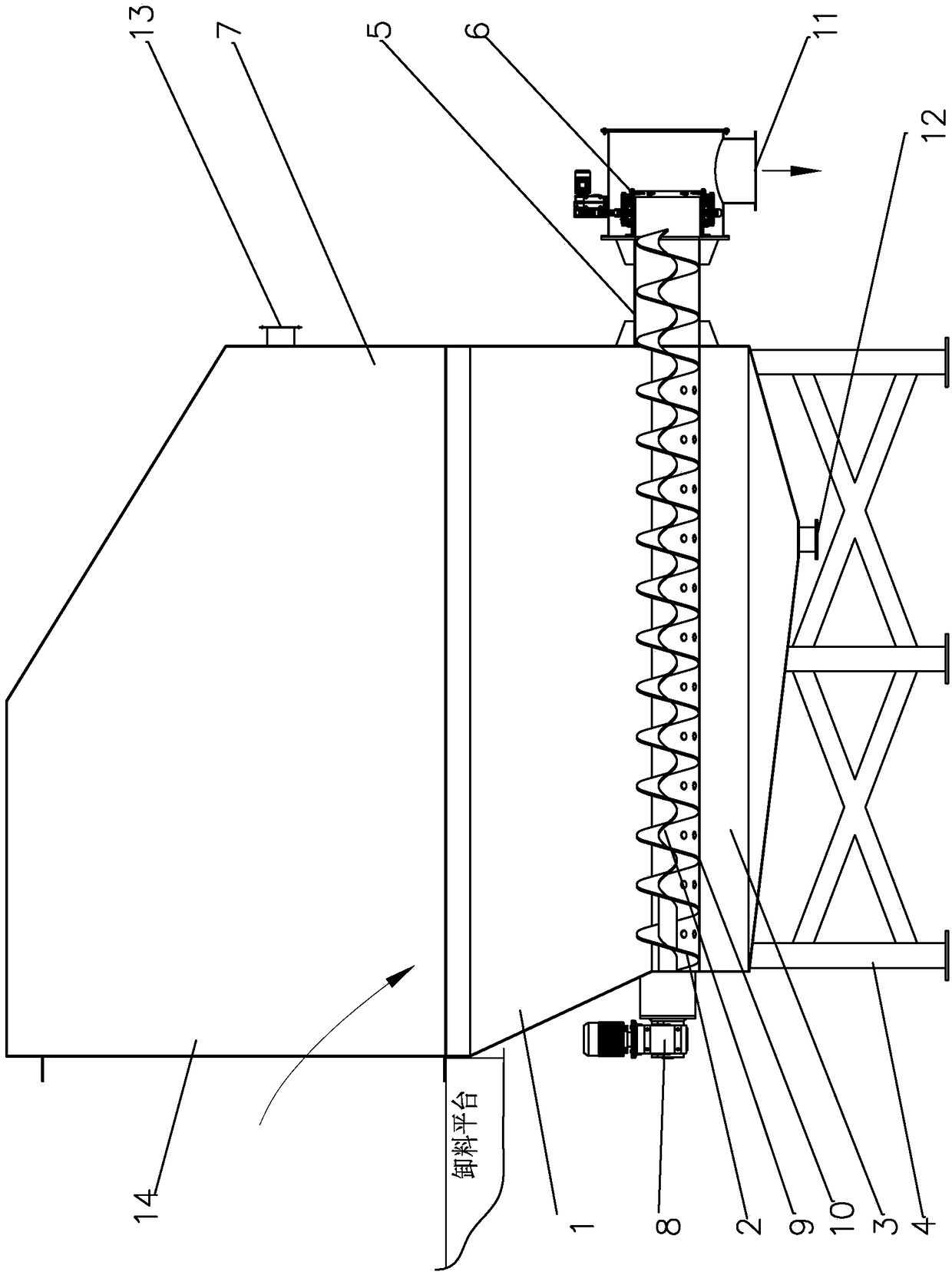

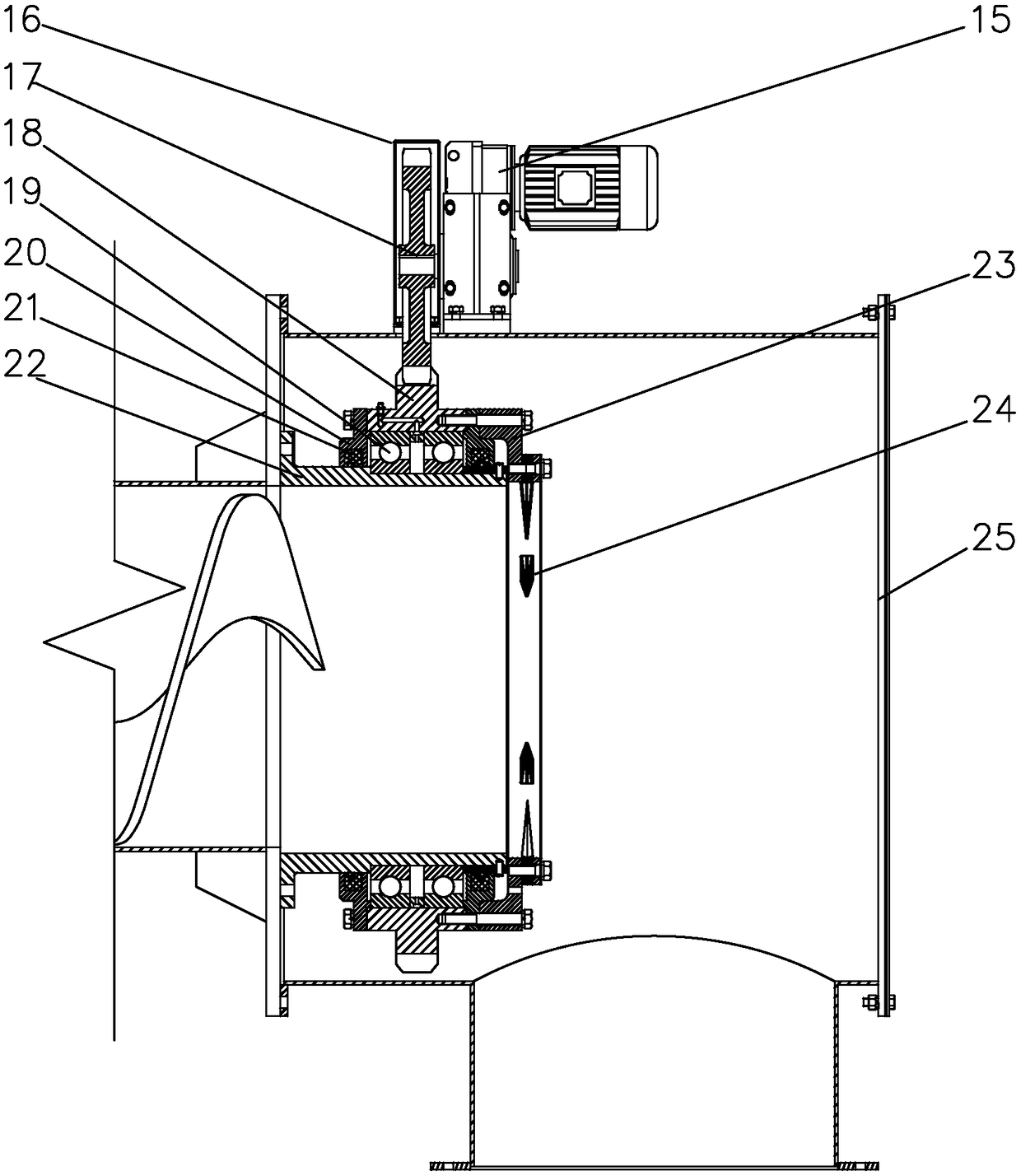

[0028] Such as Figure 1-2 As shown in the figure, a comprehensive receiving device for processing kitchen waste materials consists of a receiving tank body 1, a conveying mechanism 2, a liquid collecting tank body 3, a frame 4, an output transition support cover body 5, and a bag breaking knife group mechanism 6 , the gas-collecting cover body 7, and the discharge port 11 form a relatively airtight integrated receiving device.

[0029] The bottom of the receiving tank 1 is equipped with several rows of conveying mechanisms 2, the bottom of the receiving tank 1 is provided with a number of drain holes 10, the bottom of the receiving tank 1 is connected to the liquid collecting tank 3, and the bottom of the receiving tank 1 is spiral The leachate generated during the pushing operation is collected from the drain hole 10 into the sump body 3 . The liquid collecting tank body 3 and the receiving tank body 1 are of an integral airtight structure. The bottom of the collecting tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com