Butt joint transmission mechanism of automobile transmission test bed

A technology for automobile transmission and transmission mechanism, which is applied in the testing of machine/structural components, instruments, and mechanical components, etc. It can solve the problems of wasted man-hours, labor and high manufacturing costs, and achieve low labor participation, accurate rotation speed and practicality. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

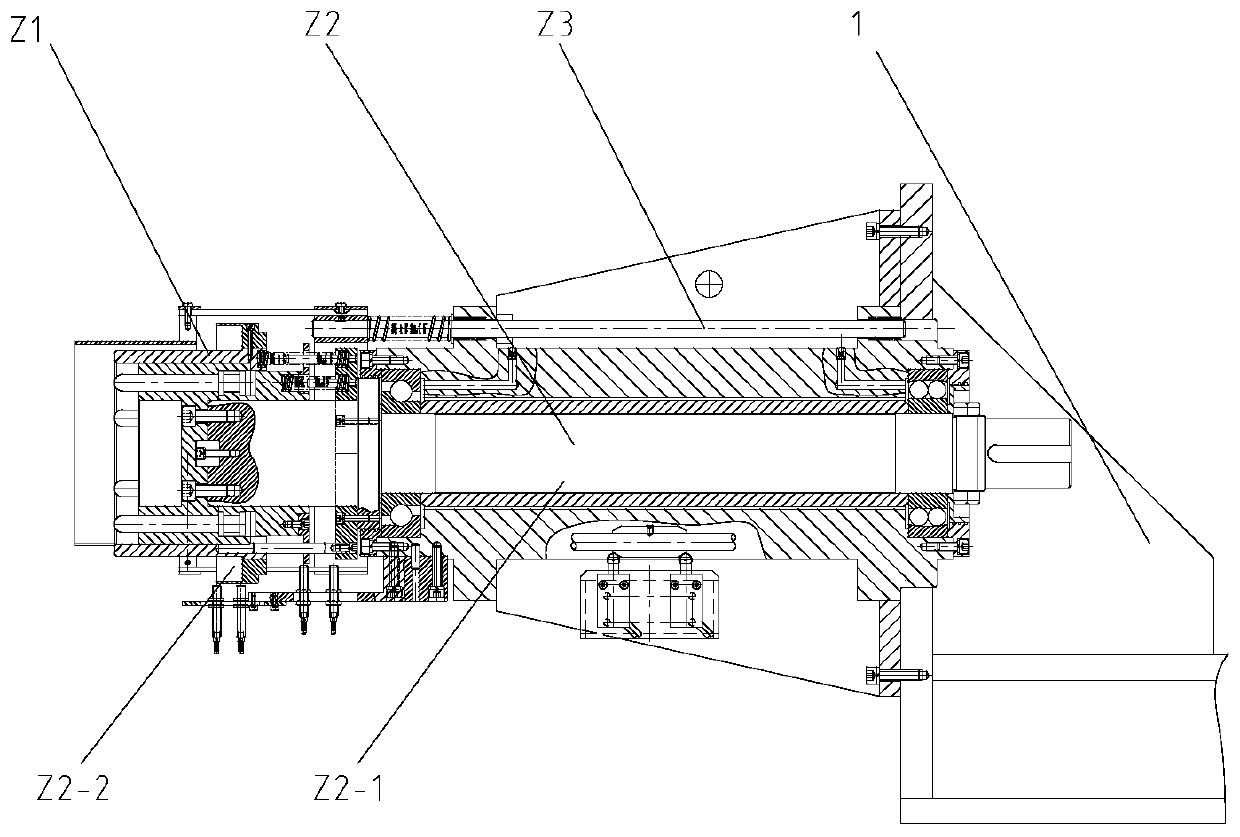

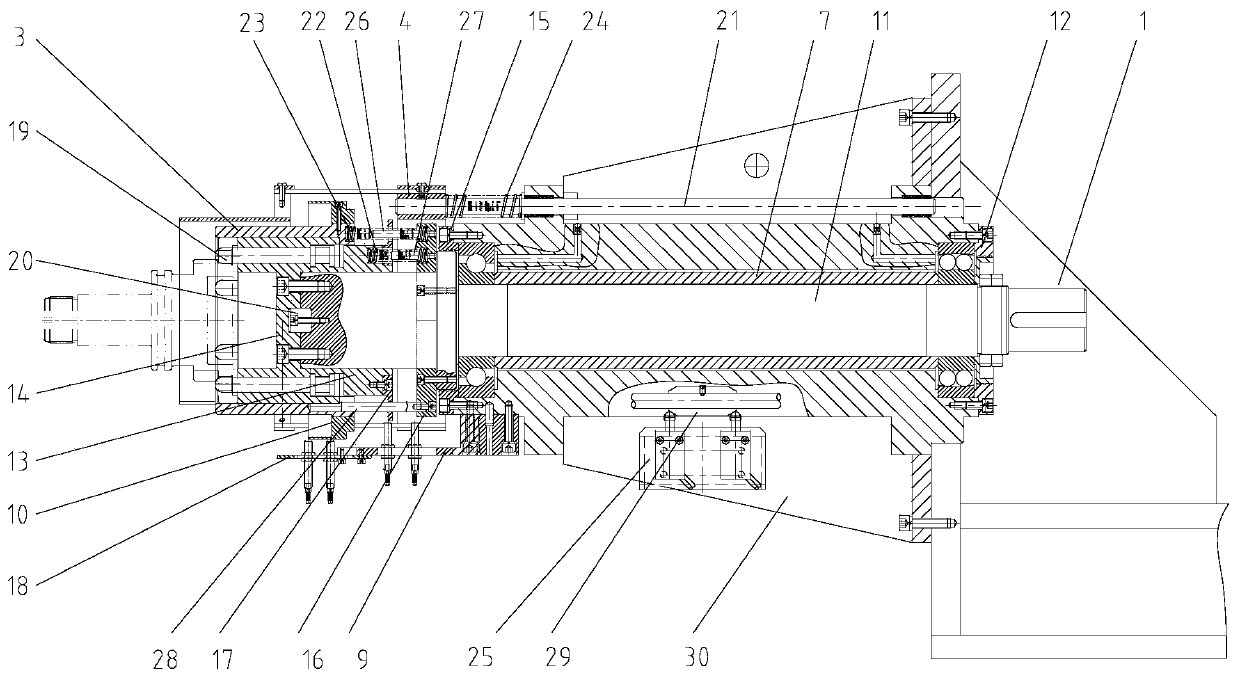

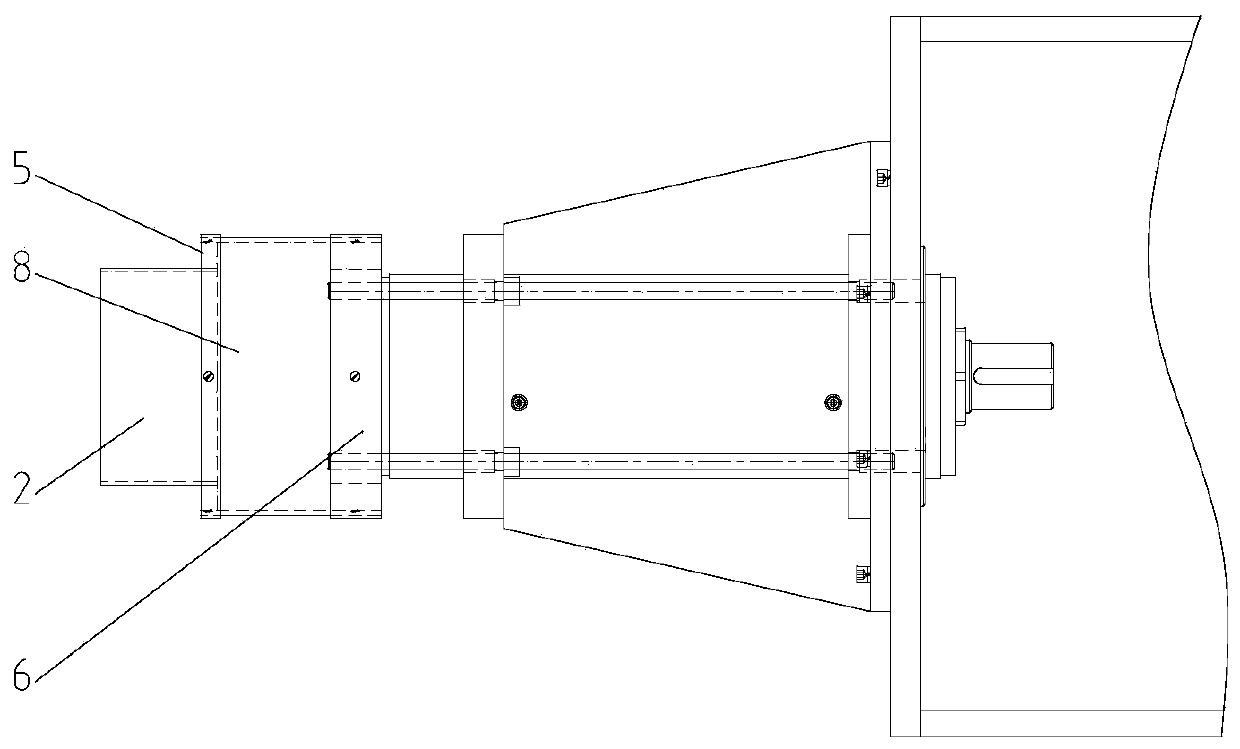

[0029] Such as figure 1 As shown, a docking transmission mechanism of an automobile transmission test bench provided by the present invention includes a structurally fixed frame 1, a transmission docking mechanism Z2, a centering, centering, and error prevention mechanism Z1, and a protection mechanism Z3; the transmission docking mechanism Z2 is arranged on a structurally fixed On the frame 1, it is used to transmit the output torque of the loading motor to the transmission flange; the centering and anti-error mechanism Z1 is arranged outside the end of the transmission docking mechanism Z2, and is in sliding contact with the transmission docking mechanism Z2, and the centering alignment The center error prevention mechanism Z1 is used to positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com