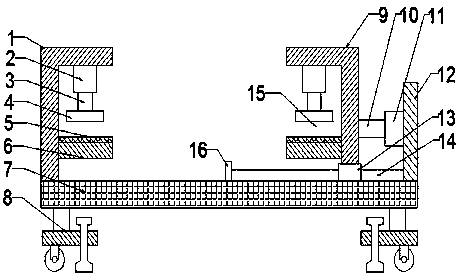

Clamping device for processing electric parts

A clamping device and technology of electrical parts, applied in the field of electrical parts processing, can solve the problems of low work efficiency, complicated operation, low quality of assembly and inspection, etc., and achieve the effect of being easy to move and fix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

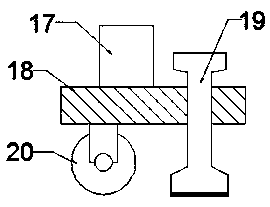

[0020] As a preferred embodiment of the present invention, the supporting device 8 is arranged at the bottom corner of the base plate 7, and the supporting device 8 includes a connecting column 17, a supporting base 18, a screw rod 19 and a roller 20; the top end of the connecting column 17 is welded At the bottom of the base plate 7, the bottom end of the connecting column 17 is welded to the upper end of the supporting base 18; the supporting base 18 is provided with a screw rod 19 and a roller 20; The movement; the screw rod 19 is arranged on the right side of the support base 18.

[0021] As a preferred embodiment of the present invention, the bottom end of the threaded rod 19 is provided with a pad.

[0022] The main outstanding features of the present invention are: the device can prevent electric parts from being crushed and anti-slip under excessive pressure; the roller and threaded rod provided can facilitate the movement and fixation of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com