Automobile part grinding tool

A technology of auto parts and tooling, which is applied in the direction of grinding/polishing safety devices, grinding machines, manufacturing tools, etc. It can solve the problems of the environment affecting the processing of auto parts, inconvenience for users, and easy to scratch auto parts, etc., to achieve Improve the dust collection effect and facilitate the grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

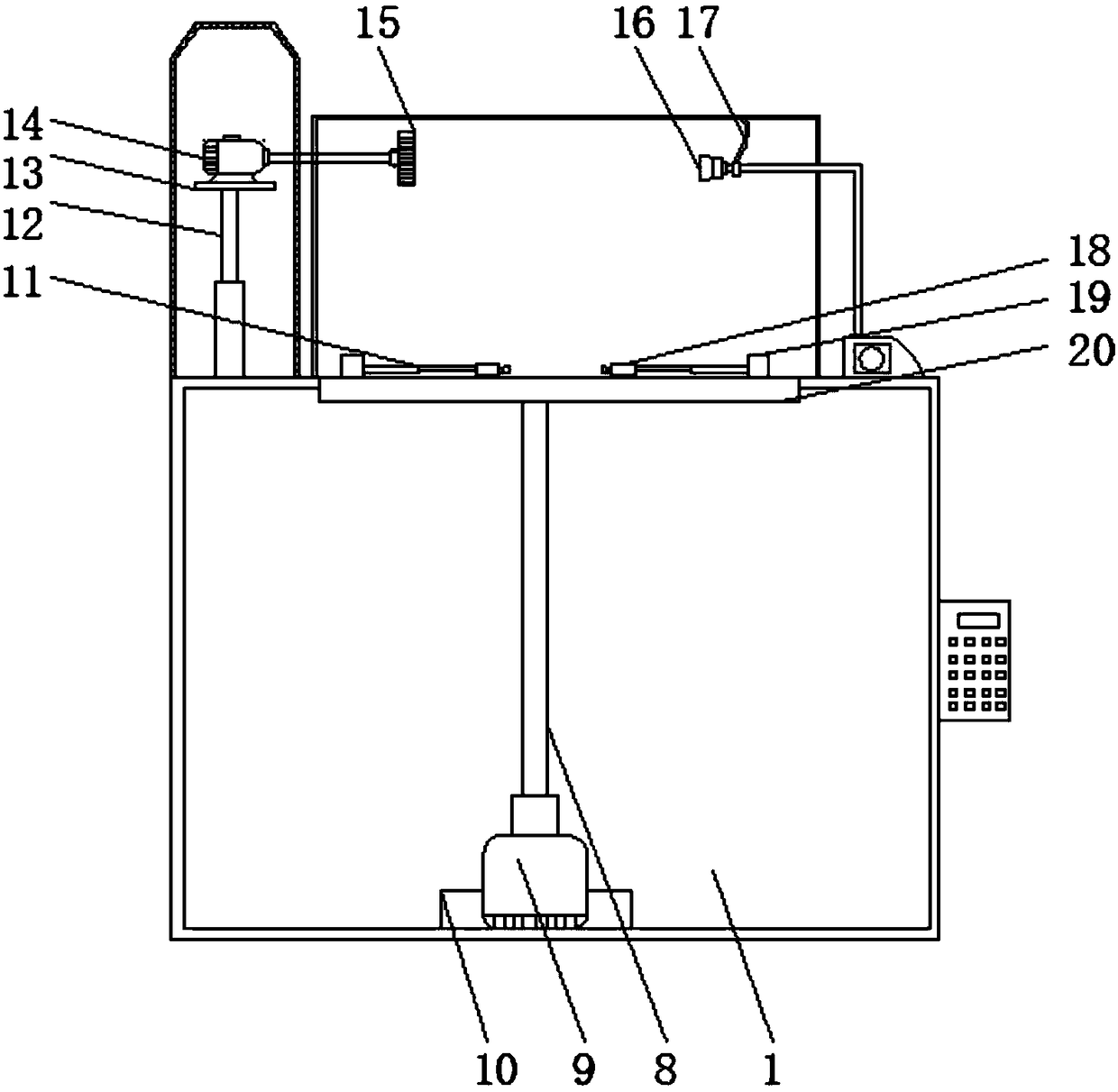

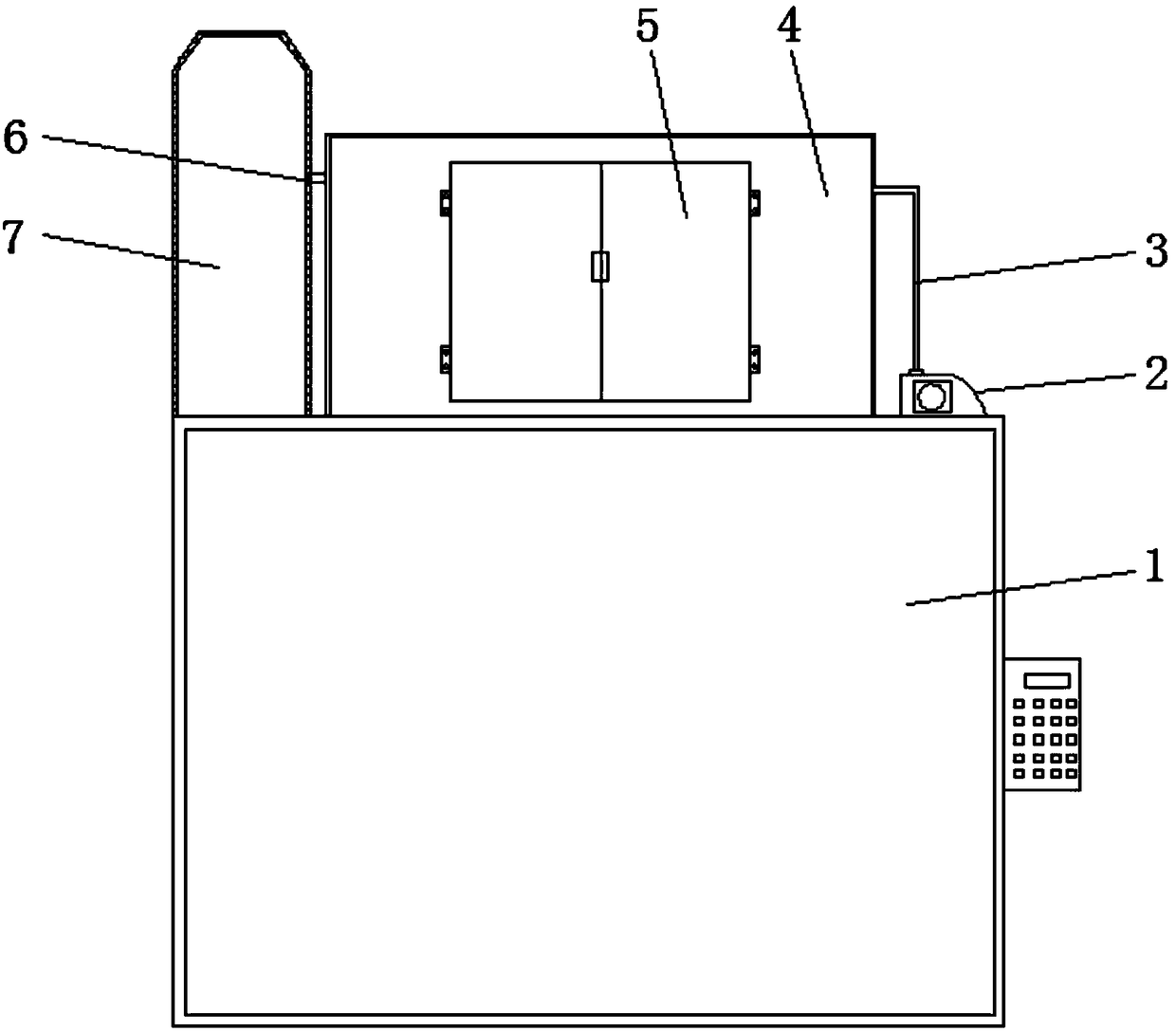

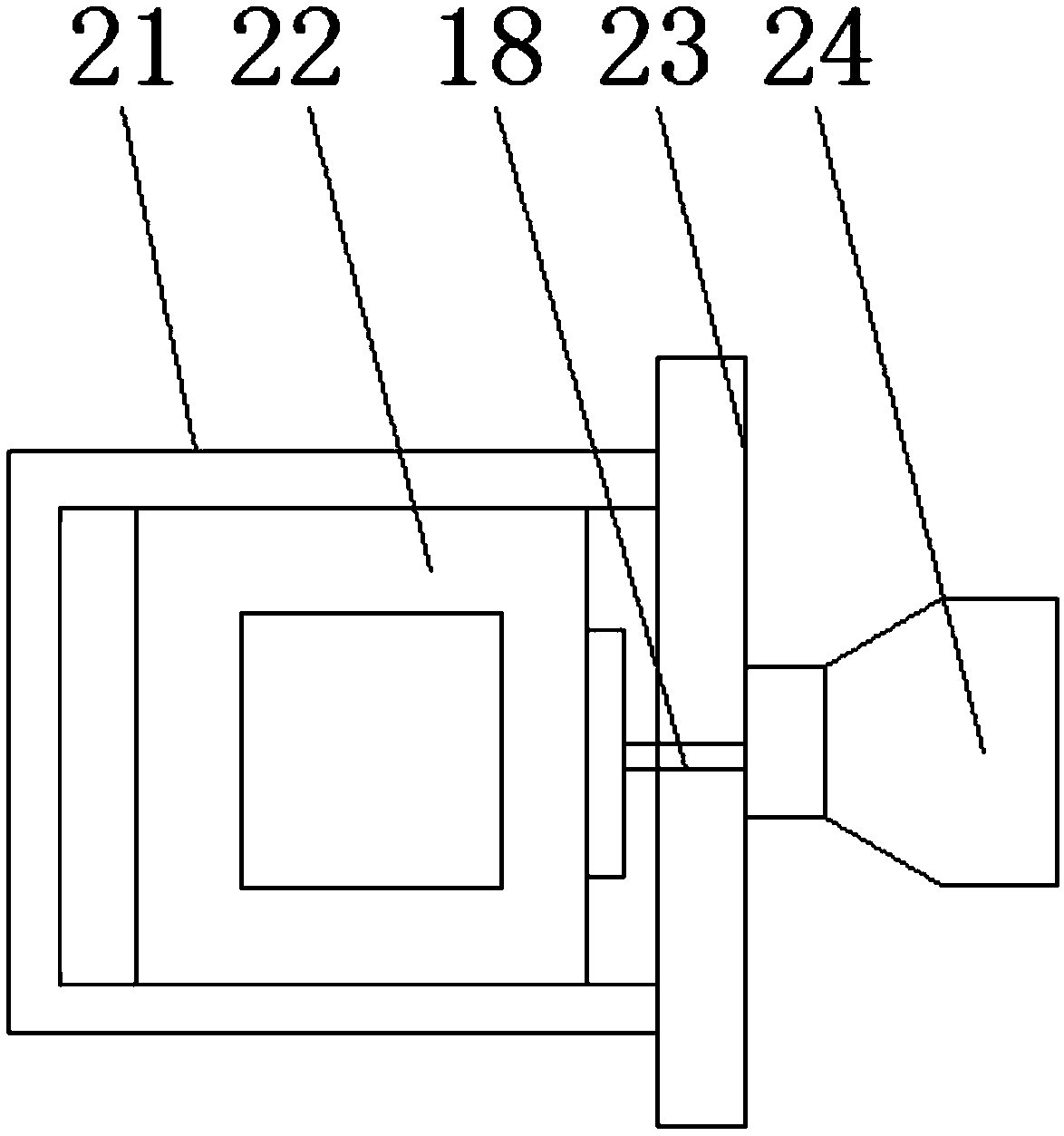

[0025] Such as Figure 1 to Figure 4 As shown, a kind of tooling for polishing auto parts, including a base 1, a transparent dust cover 4, an installation box 21, a bottom plate 23, a rubber suction cup 24 and a sleeve 25, a PLC controller is arranged on one side of the base 1, and the upper side of the base 1 Housing 7, transparent dustproof cover 4, vacuum cleaner 2 and first electric telescopic rod 12 are provided. The first motor 14 is arranged on the top, and the first motor 14 is connected with one end of the grinding shaft 6 through a coupling, and the other end of the grinding shaft 6 passes through the elongated through hole on the housing 7 and is connected with the grinding tool 15, and the grinding tool 15 Connect with the grinding shaft 6 through the fixing bolt, the fixing bolt penetrates into the threaded hole on the grinding tool 15 and the grinding shaft 6, the lower end of the fixing bolt is threadedly connected with a nut, the grinding tool 15 is positioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com