Manufacturing method of image-text assembly, image-text assembly and tire mold side plate

A manufacturing method and technology of tire molds, applied in the field of tire mold manufacturing, can solve problems such as rubber wool, and achieve the effect of high tire yield and easy transportation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

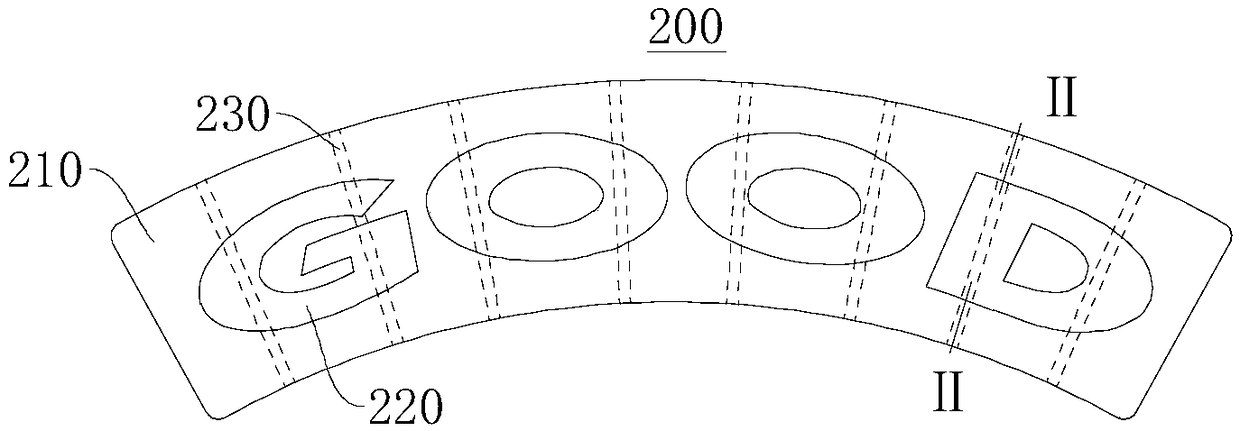

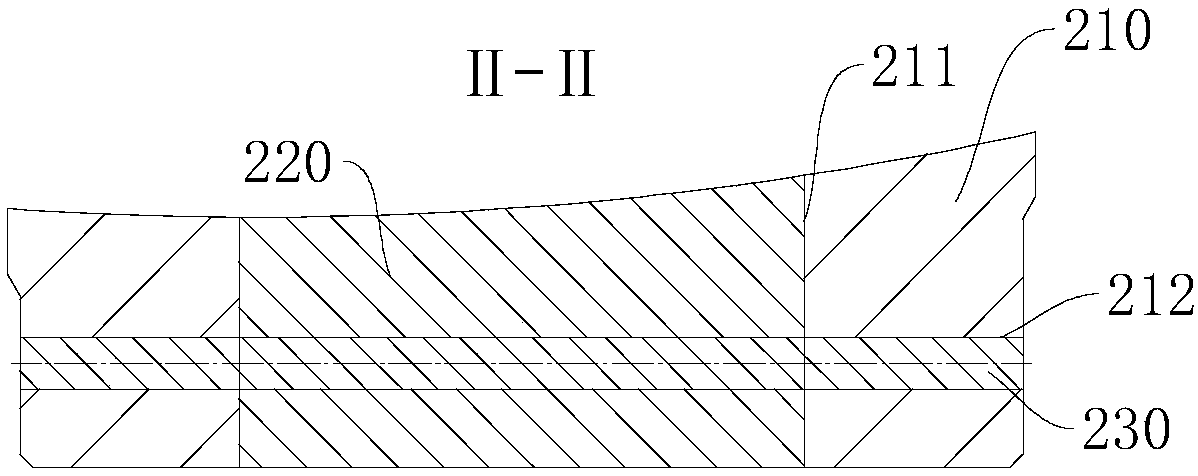

[0051] figure 1 A schematic structural diagram of the graphic component 200 provided in this embodiment, figure 2 for figure 1 Schematic diagram of the cross-sectional structure at II-II. Please refer to figure 1 and figure 2 , the present embodiment provides a method for manufacturing the graphics and text component 200 to improve the problem of rubber fluff in tires vulcanized by the existing tire mold 020 .

[0052] The manufacturing method of the graphic component 200 provided by this embodiment is further described below:

[0053] The manufacturing method of the graphic component 200 provided by this embodiment includes the following steps:

[0054]SO1: Open a picture and text block slot 211 on the picture and text frame 210 .

[0055] Process along the outline of the pattern or font that needs to be set on the graphic component 200 to obtain graphic block grooves 211 . Specifically, the picture and text frame 210 is clamped on a cutting machine, and the outline ...

Embodiment 2

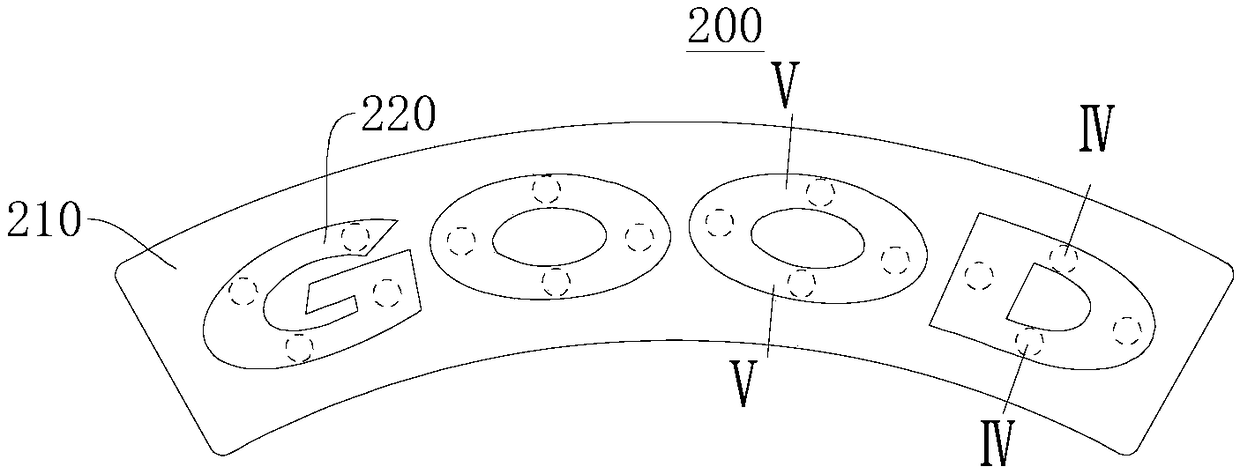

[0062] image 3 A schematic structural diagram of the graphic component 200 provided in this embodiment, Figure 4 for image 3 Schematic diagram of the cross-sectional structure at Ⅳ-Ⅳ, Figure 5 for image 3 Schematic diagram of the cross-sectional structure at Ⅴ-Ⅴ. Please refer to image 3 , Figure 4 and Figure 5 , the present embodiment also provides a method for manufacturing a picture-text component 200, which is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that the connection between the picture-text frame 210 and the picture-text block 220 different ways.

[0063] Specifically, in the present embodiment, the picture and text block groove 211 processed on the picture and text frame 210 is a half groove, and the side opposite to the picture and text block groove 211 is provided with a fixing groove 213 on the picture and text frame 210. The text block slots 211 are communicated with each other by openi...

Embodiment 3

[0065] Figure 6 A partial structural schematic diagram of the tire mold side plate 010 provided in this embodiment, Figure 7 for Figure 6 Schematic diagram of the cross-sectional structure at VII-VII, Figure 8 for Figure 7 The enlarged schematic diagram of the local structure at VIII. Please refer to Figure 6 , Figure 7 and Figure 8 , this embodiment provides a tire mold side plate 010, the tire mold side plate 010 includes a side plate body 100 and a graphic component 200 manufactured by the manufacturing method of the graphic component 200 described in Embodiment 1.

[0066] In this embodiment, the side plate body 100 has a sidewall shaping vulcanization surface 110 and a bottom surface 120 disposed opposite to the sidewall shaping vulcanization surface 110 . A mounting groove 130 is defined on the sidewall sizing and vulcanizing surface 110 of the side plate body 100 , and a connecting hole 140 penetrating from the bottom surface 120 to the mounting groove 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com