Back plate feeding manipulator fixture

A fixture device and manipulator technology, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems that four corner codes cannot be placed in the feeding position, inconvenient for processing and management, and inconvenient for reclaiming materials. Facilitate processing management, meet on-site process requirements, and reduce manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

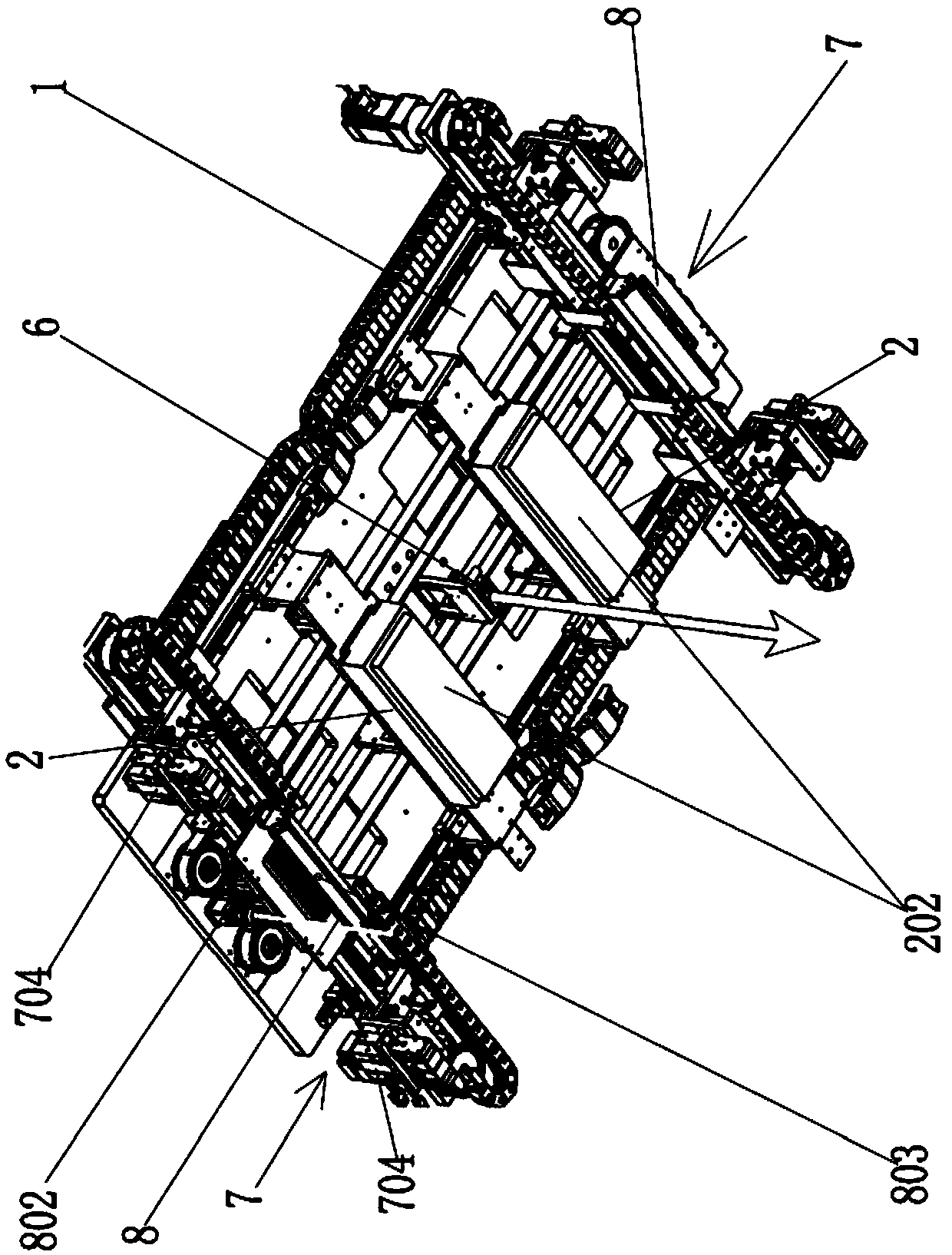

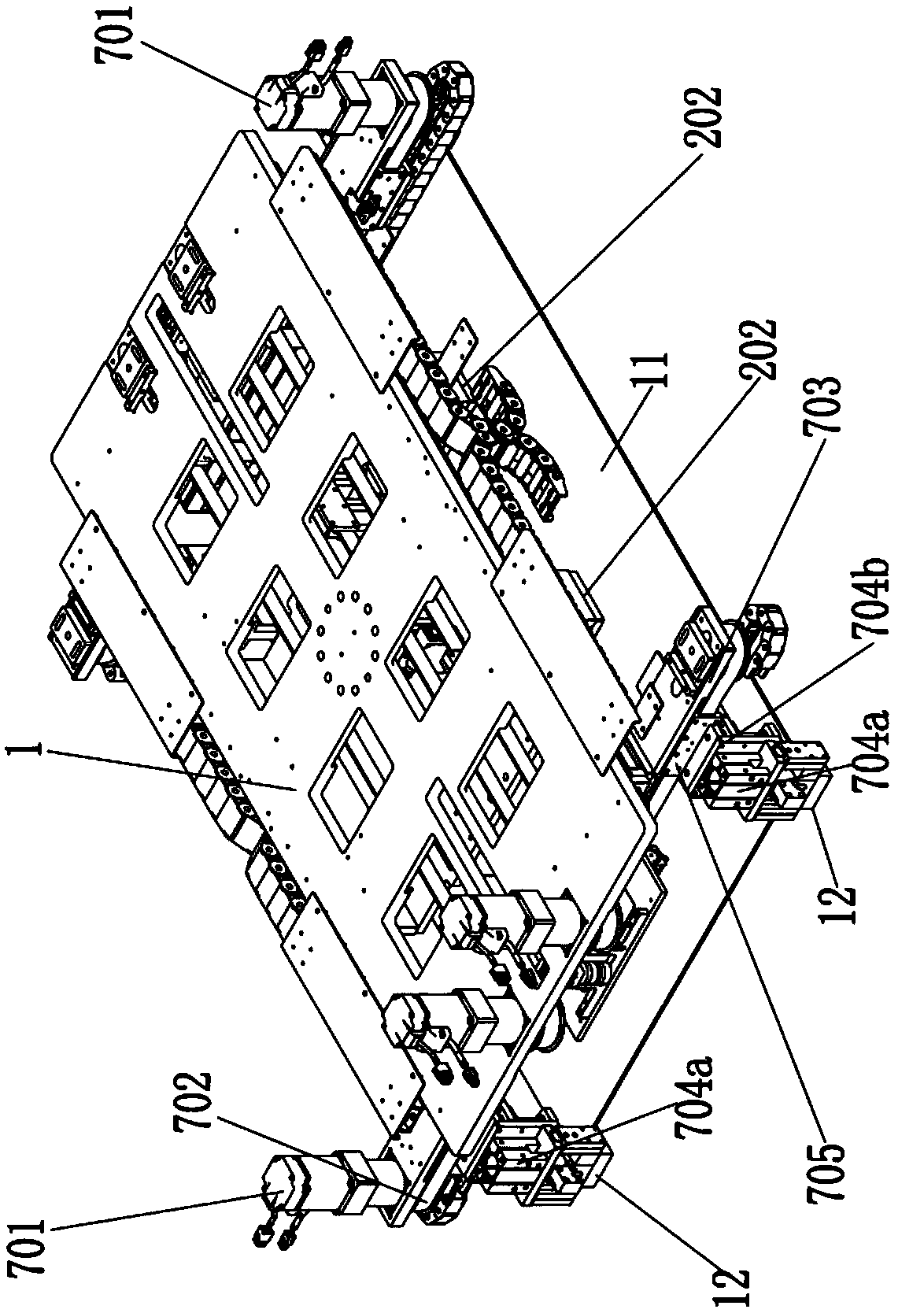

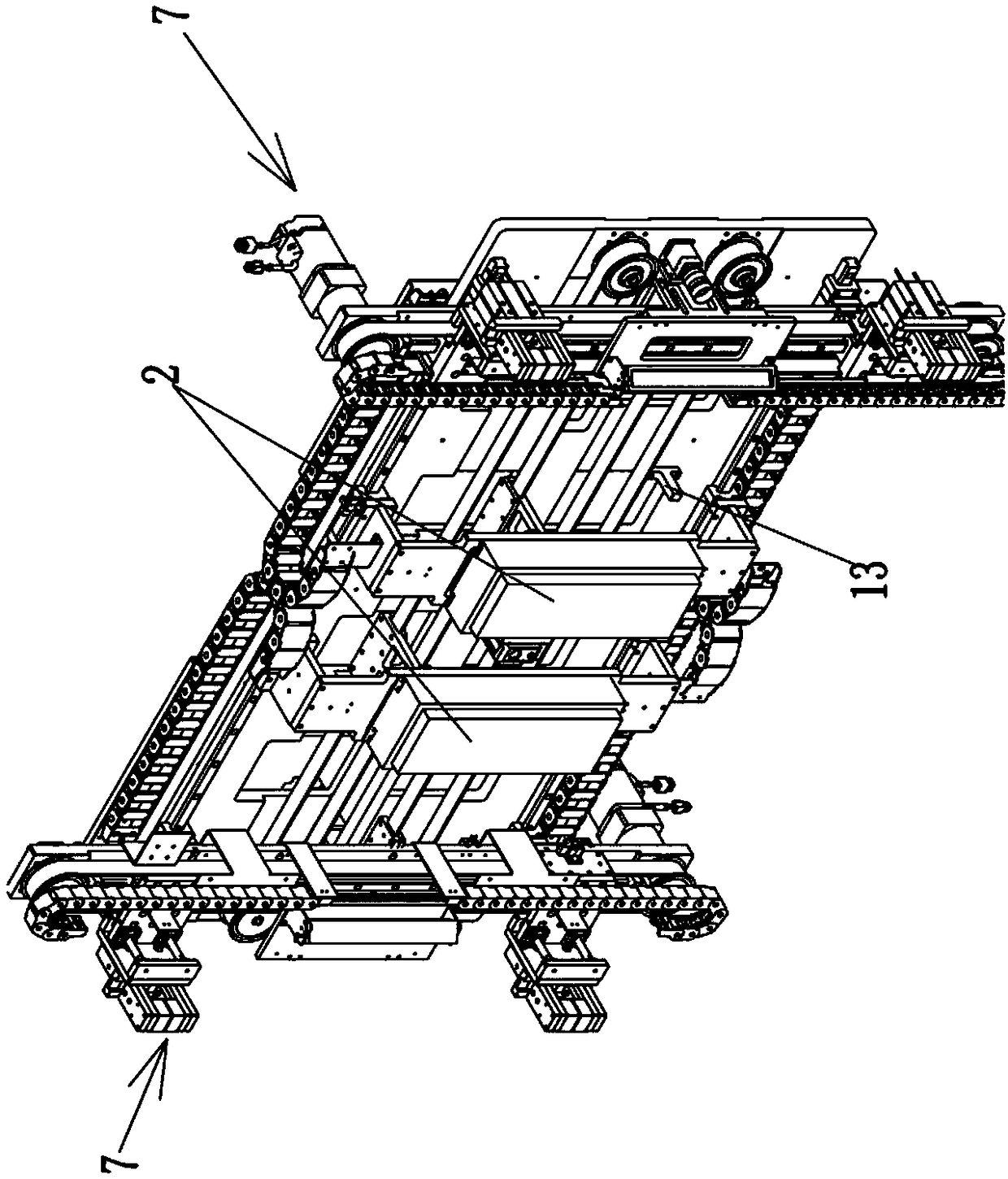

[0035] Below, the product 11 is taken as an example of a TV backplane, and the present invention is further described in conjunction with the accompanying drawings and specific embodiments.

[0036] to combine figure 1 , 2 , 3, and 10, the fixture device of the backplane feeding manipulator includes the following parts:

[0037] The fixture main seat 1 connected with the execution end of the manipulator;

[0038] A pair of sucker group mechanisms 2 relatively slidably installed on the fixture main base 1 and slide horizontally along the X direction, the sucker group mechanisms 2 are used to absorb the product 11;

[0039] A suction cup group distance adjustment mechanism installed on the clamp main base 1 for driving the two suction cup group mechanisms 2 to slide relative to each other;

[0040] A pair of corner code clamping mechanisms 7 respectively arranged at the two ends of the clamp main seat 1;

[0041] A corner code distance adjustment mechanism installed on the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com