Multi-injection fuel injection rule measuring device and measuring method thereof

A fuel injection and multi-injection technology, which is used in measurement devices, fuel injection devices, charging systems, etc., can solve the problems of the difficulty of obtaining the bulk elastic modulus K accurately and the influence of the measurement accuracy of the fuel injection rate, so as to reduce flooding, The effect of reducing distractions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

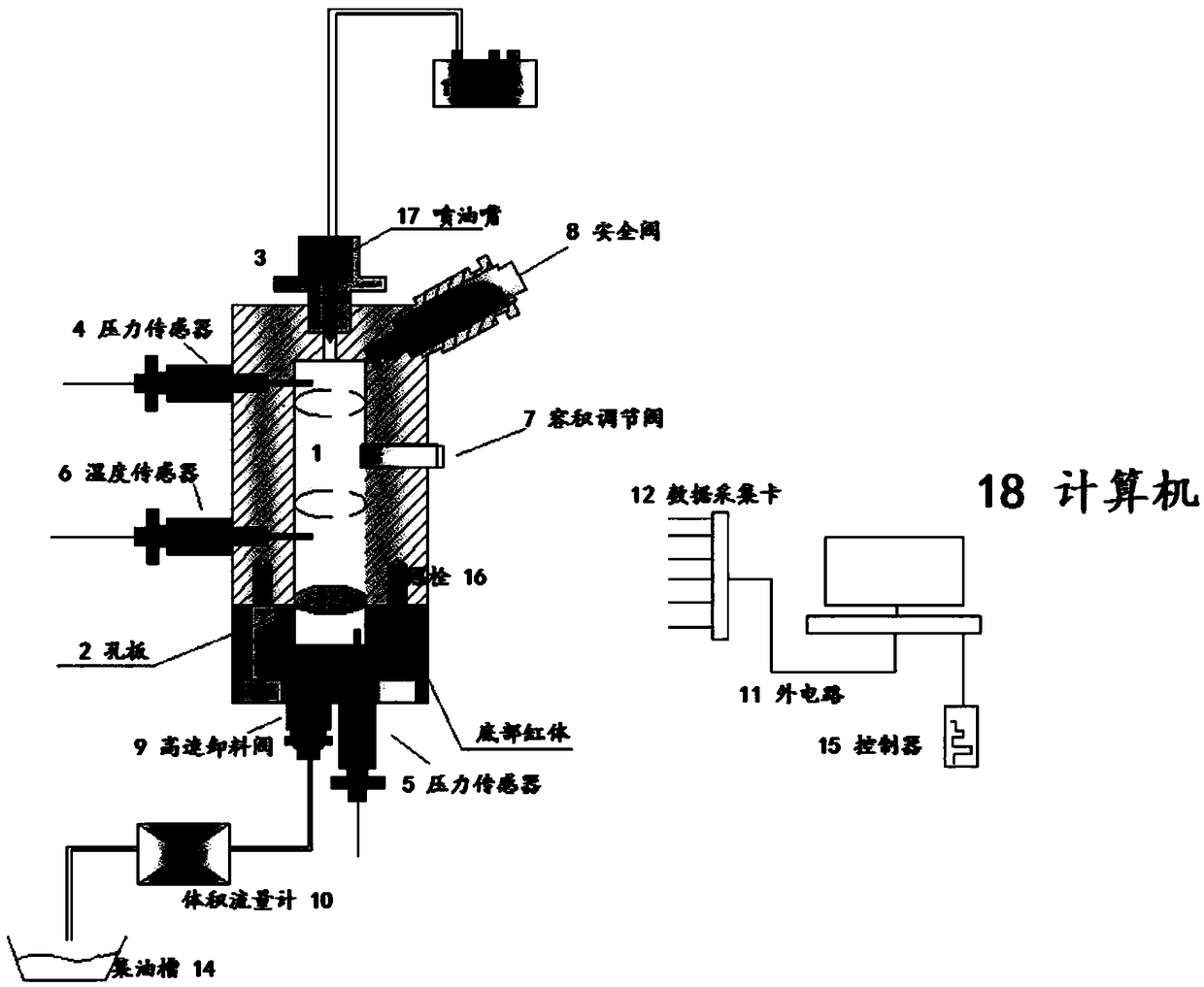

[0025] The high-precision fuel injection rate detection device suitable for multiple injections of the present invention includes a cylindrical measuring constant volume cavity 1, an orifice filter 2 installed at the bottom of the cylindrical cavity, a fuel injector mounting bracket 3, a fuel injection The main body of the measuring instrument composed of a device 17 and two pressure sensors 4 and 5, a temperature sensor 6, a volume regulating valve 7, a safety valve 8, a high-speed discharge valve 9, a volume flowmeter 10, an external circuit 11, and a data acquisition card 12 , the data processing and control system that controller 15, computer 18 are formed and the peripheral equipment that high-pressure oil pipe 13, oil sump 14, connecting bolt 16 are formed, it is characterized in that: fixed volume chamber 1 is set on measuring instrument main body, the bottom of constant volume chamber The orifice filter 2 is installed, and the pressure sensors 4 and 5 are respectively i...

specific Embodiment 2

[0035] The high-precision fuel injection rate detection device suitable for multiple injections of the present invention includes a cylindrical measuring cavity, an orifice filter, two pressure sensor mounting brackets at the upper and lower parts, a temperature sensor mounting bracket, and a valve mounting bracket. The main body of the measuring instrument and the data processing and control system composed of two pressure sensors, one temperature sensor, volume regulating valve, safety valve, high-speed discharge valve, volume flowmeter, external circuit and computer, etc., are characterized by: A constant volume chamber is set on the main body, and an orifice filter is installed at the bottom of the constant volume chamber. Pressure sensors are installed before and after the orifice filter to measure the pressure change before and after filtering. The fuel injector is installed in the measuring chamber along the axis of the cylindrical cavity. The upper part of the fuel inje...

specific Embodiment 3

[0053] A high-precision multi-injection fuel injection rate detector equipped with an orifice filter, including a cylindrical measuring cavity, an orifice filter, two pressure sensor mounting brackets at the upper and lower parts, a temperature sensor mounting bracket and a valve mounting bracket The main body of the measuring instrument and the data processing and control system composed of two pressure sensors, one temperature sensor, volume regulating valve, safety valve, high-speed unloading valve, volume flow meter, external circuit and computer, etc., are characterized by: A constant volume chamber is set on the main body of the measuring instrument, and an orifice filter is installed at the bottom of the constant volume chamber. Pressure sensors are installed before and after the orifice filter to measure the pressure change before and after filtering. The fuel injector is installed along the axis of the cylindrical cavity. The upper part of the measurement cavity is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com