Solid pesticide drying device

A drying device and pesticide technology, applied in drying, drying machine, solid separation, etc., can solve the problems of low drying efficiency, harmful working environment, easy caking, etc., and achieve high drying efficiency and good product quality , Improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

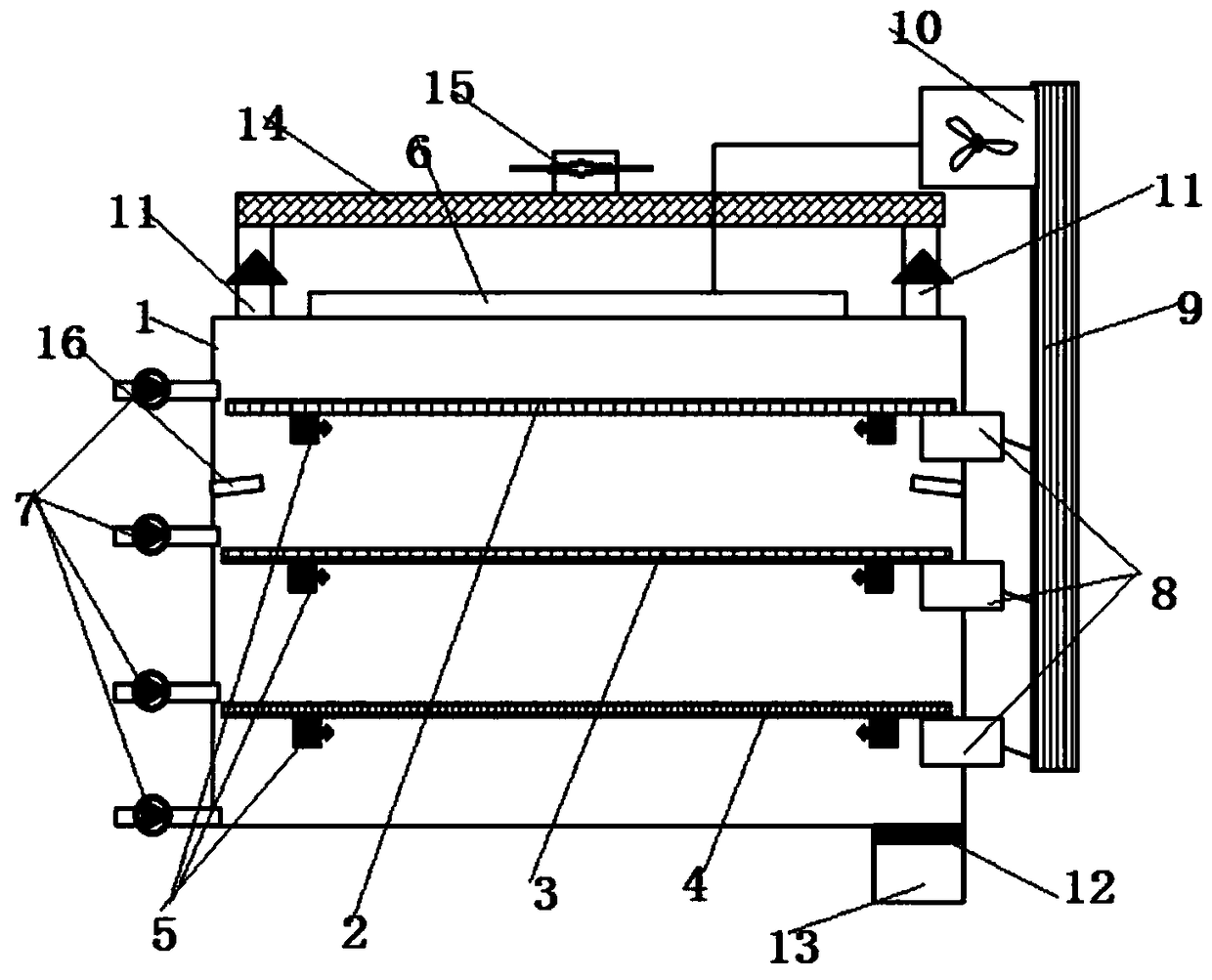

[0015] see figure 1 , a solid pesticide drying device, comprising a housing 1, a first sieve plate 2, a second sieve plate 3 and a third sieve plate 4 are sequentially arranged in the shell 1 from top to bottom, the first sieve plate 2. A vibrator 5 is provided at the lower end of the second sieve plate 3 and the third sieve plate 4; the apertures of the first sieve plate 2, the second sieve plate 3, and the third sieve plate 4 are successively reduced; the first sieve plate 4 The sieve plate 2, the second sieve plate 3, and the third sieve plate 4 are provided with heating wires inside; One side of 4 is provided with a row of horizontal air blowing pipes 7, the outlet of the horizontal air blowing pipes 7 is located on the upper surface of the sieve plate, and the inlet is arranged outside the housing 1; There is a collection tank 8, the opening of the collection tank 8 is facing the edge of the sieve plate, the collection tank 8 is connected to the lifting pipeline 9 throug...

Embodiment 2

[0017] see figure 1 , as an improvement of the present invention, a row of horizontal blowing pipes 7 is arranged on one side of the inner bottom of the housing 1, and the discharge port 12 is arranged on the other side opposite to the horizontal blowing pipes 7. A collection chamber 13 is provided below the port 12 . It is convenient to collect the pesticides that fall on the bottom of the housing 1 and dry.

Embodiment 3

[0019] see figure 1 , as an improvement of the present invention, the air extraction pipes 11 are arranged in two groups, the outlets of the air extraction pipes 11 are connected to the packing pipe 14, and the organic gas adsorbent is arranged in the packing pipe 14. Increase gas convection, improve drying efficiency, and avoid direct discharge of organic gas, which will cause harm to the human body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com