Multi-channel sampling system

A sampling system and multi-channel technology, applied in the field of multi-channel sampling system, can solve problems such as unable to sample normally, unable to detect coal sample quality, high water content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The core of the present invention is to provide a multi-channel sampling system, which can avoid downtime due to failure and ensure continuous production by switching coal sample transmission lines during the sampling process.

[0029] In order to enable those skilled in the art to better understand the technical solution of the present invention, the multi-channel sampling system of the present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

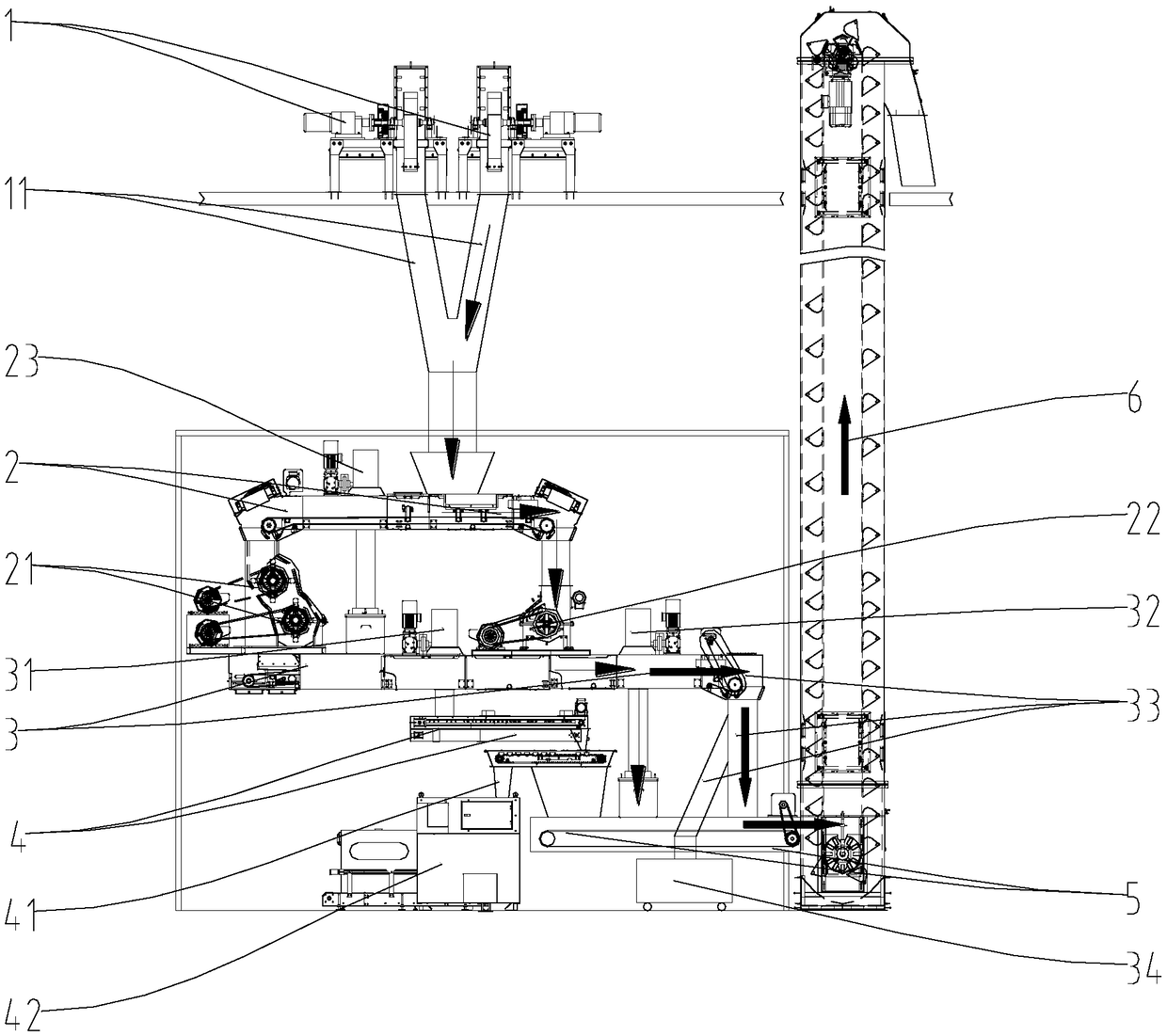

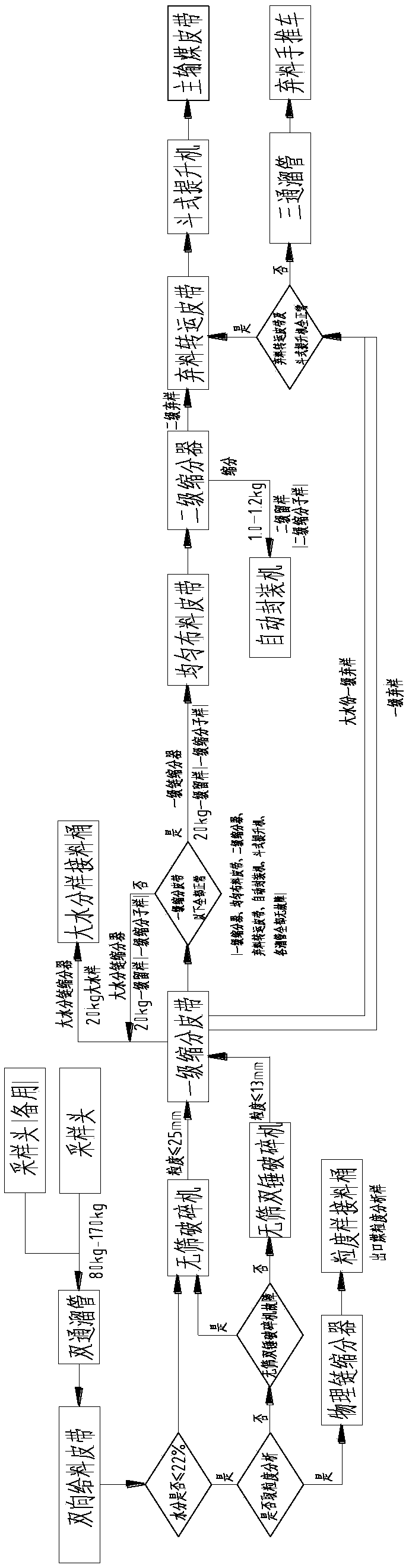

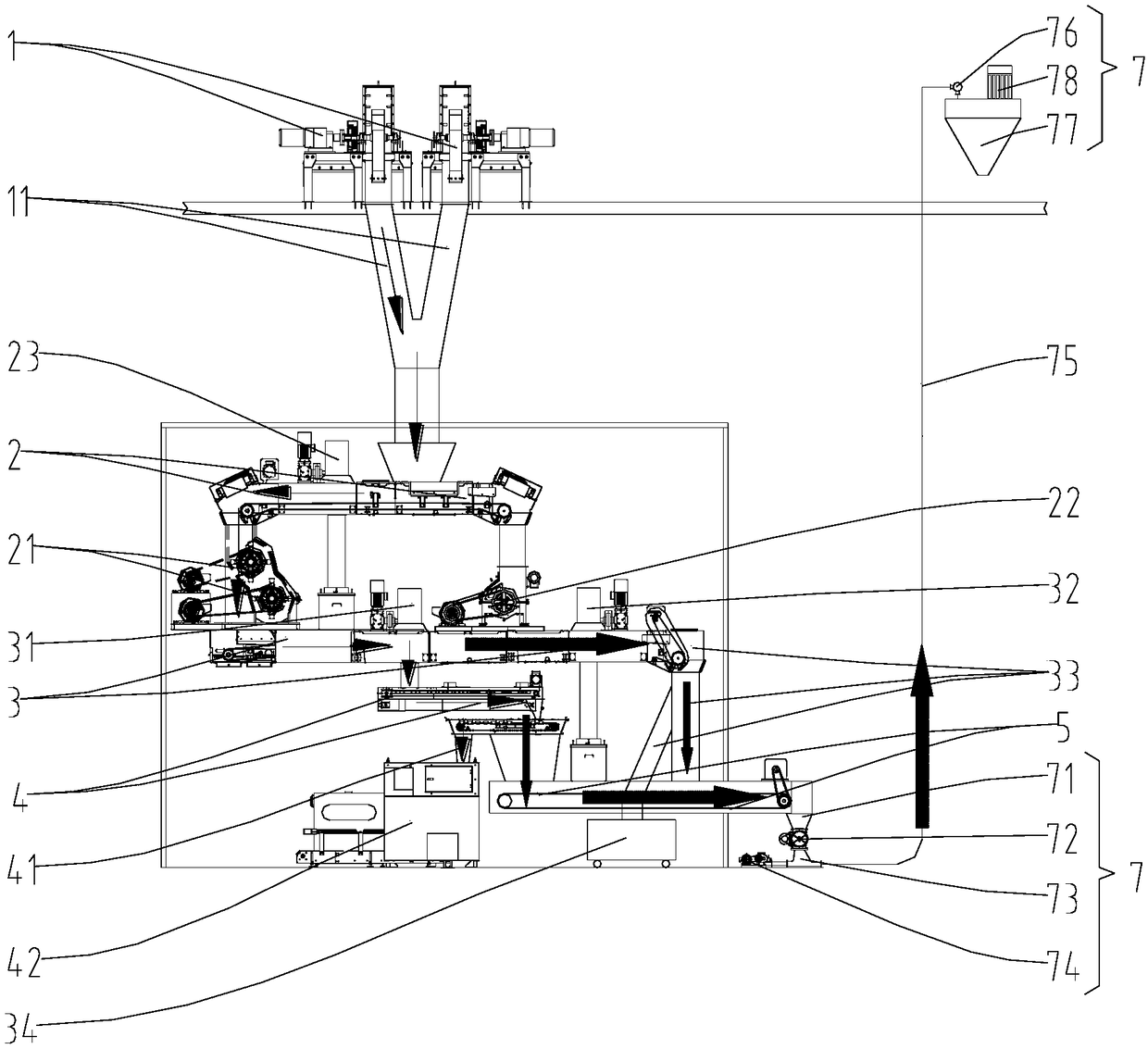

[0030] Such as Figure 1A and Figure 2A Shown, are respectively the structural diagrams of two different embodiments of the multi-channel sampling system provided by the present invention, which include structures such as a sampling head 1, a bidirectional feeding belt 2, a first-stage reduction belt 3, and a uniform distribution belt 4, wherein the sampling There are at least two groups of sampling heads 1, and each group of sampling heads 1 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com