Construction method for simulation system based on hot-rolling L2 process control system

A process control system and simulation system technology, applied in general control systems, control/regulation systems, instruments, etc., can solve problems such as limited test time, scrap steel, and insufficient testing of new functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

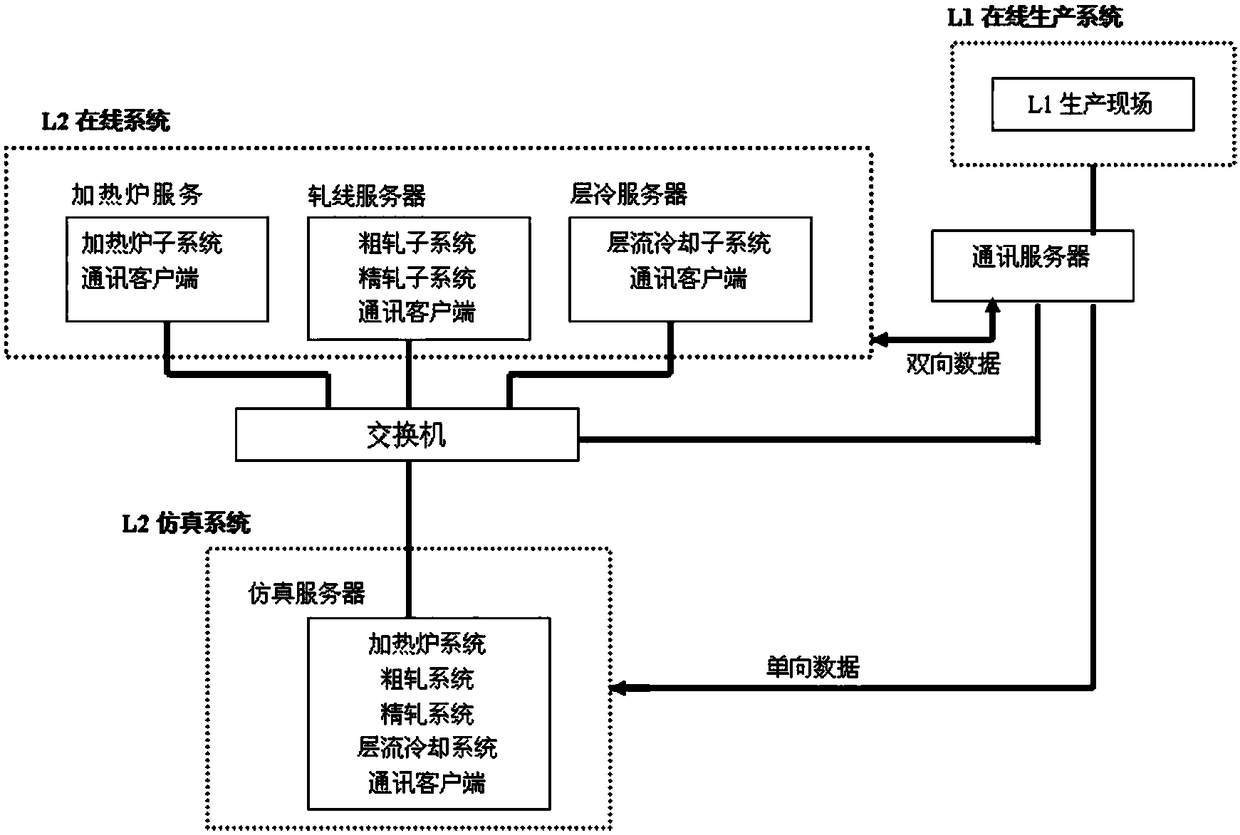

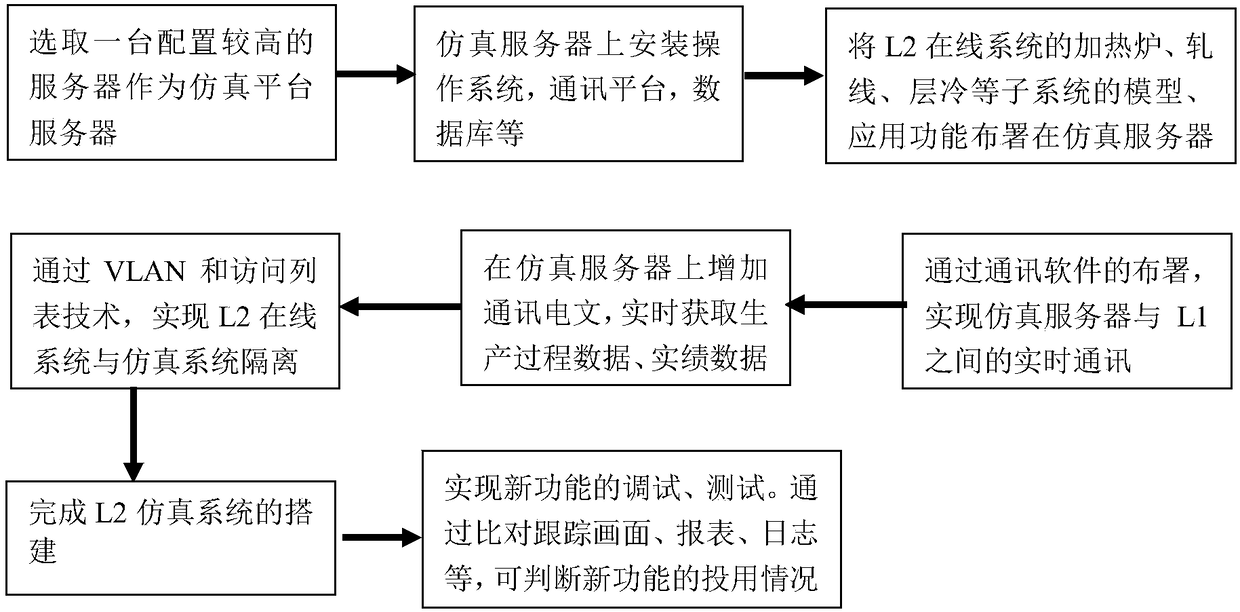

Method used

Image

Examples

Embodiment example

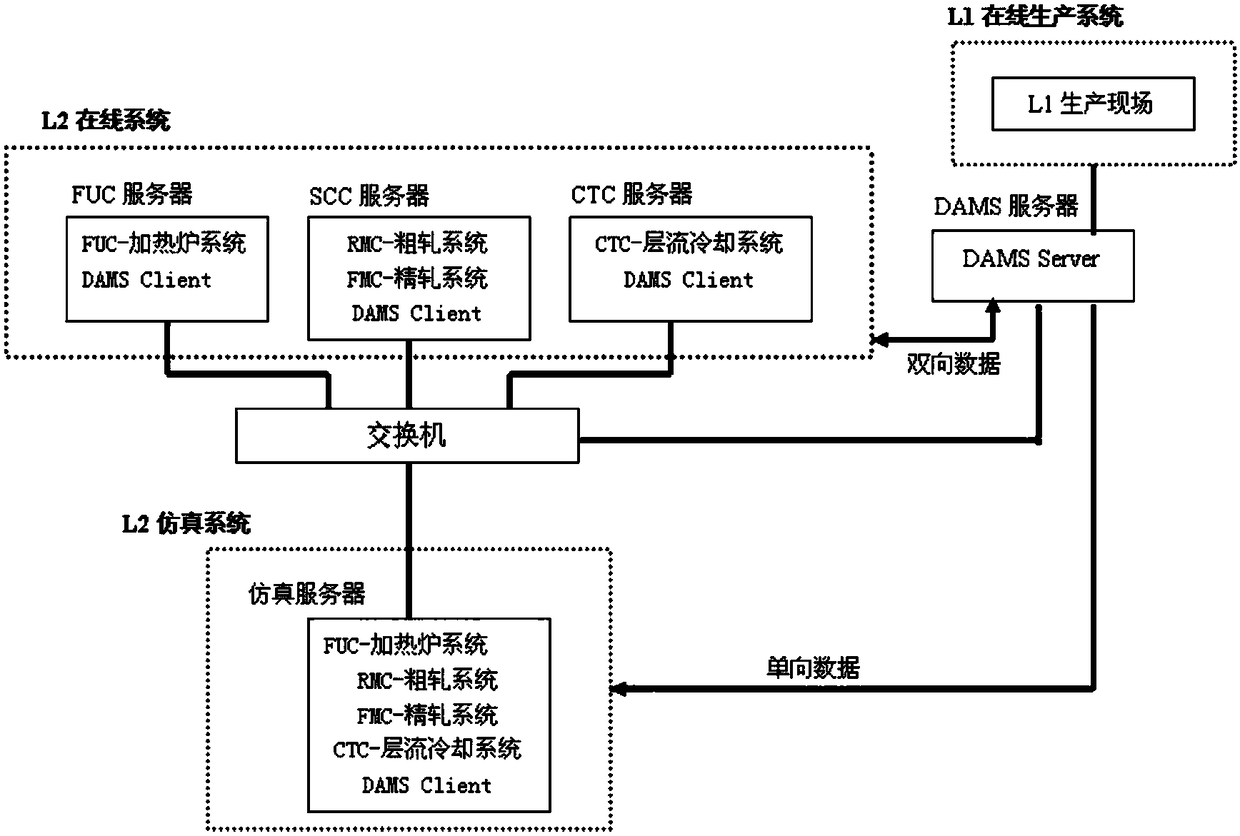

[0068] Meishan Steel 1780 hot rolling L2 process control system, using this method to build a simulation system platform. Such as image 3 :

[0069] Step S11 above: choose a HP DL580 G2 server as the simulation system server, install Windows2003 Server R2 operating system, and configure 6 disks in RAID1+0 mode to realize disk one-to-one mirroring and redundancy.

[0070] The above step S12: add the simulation system server to the L2 system with the line, the simulation server is connected to the L2 core switch, the IP address of the simulation system server is: 172.16.0.2, and use VLAN and access list technology to isolate the simulation from the online system network , the online system is on VLAN10, the simulation system is on VLAN20, and the IP address of VLAN20 is: 172.16.0.1. The network segment of the online system is 168.151.100.***, and the network segment of the simulation system is 172.16.0.***. Add a network card in the DAMS server with IP address: 172.16.0.3, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com