Film-bonded all-black photovoltaic module and manufacturing method thereof

A black light and film technology, which is used in photovoltaic power generation, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of tandem belt and bus belt reflection, affecting the effect of sunlight absorption, aesthetic defects, etc., to reduce light pollution, The effect of improving the aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific drawings and embodiments.

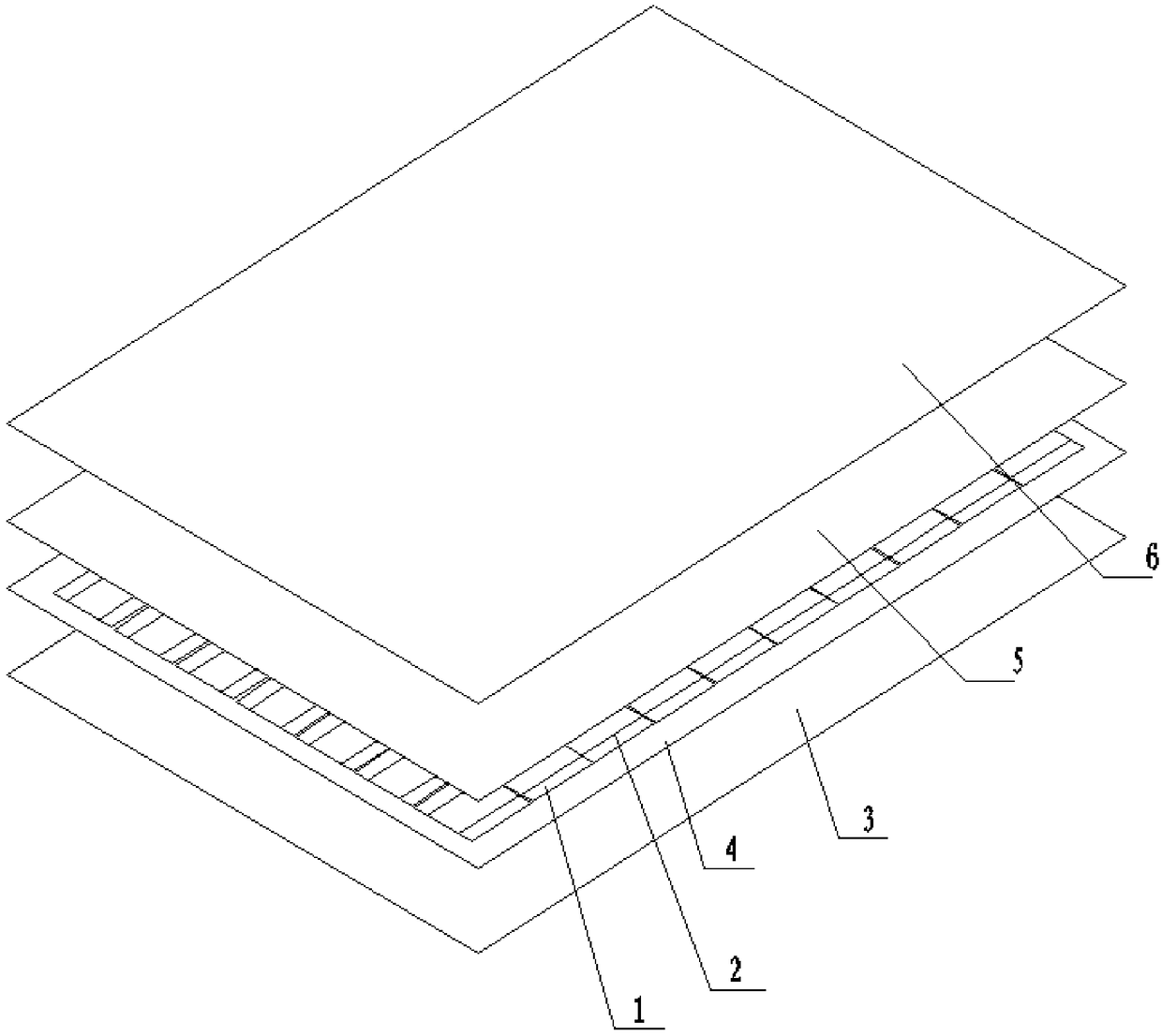

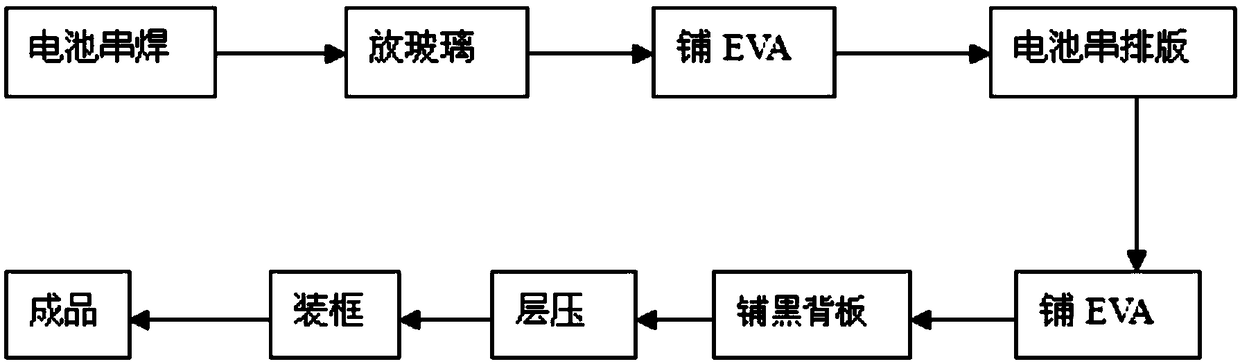

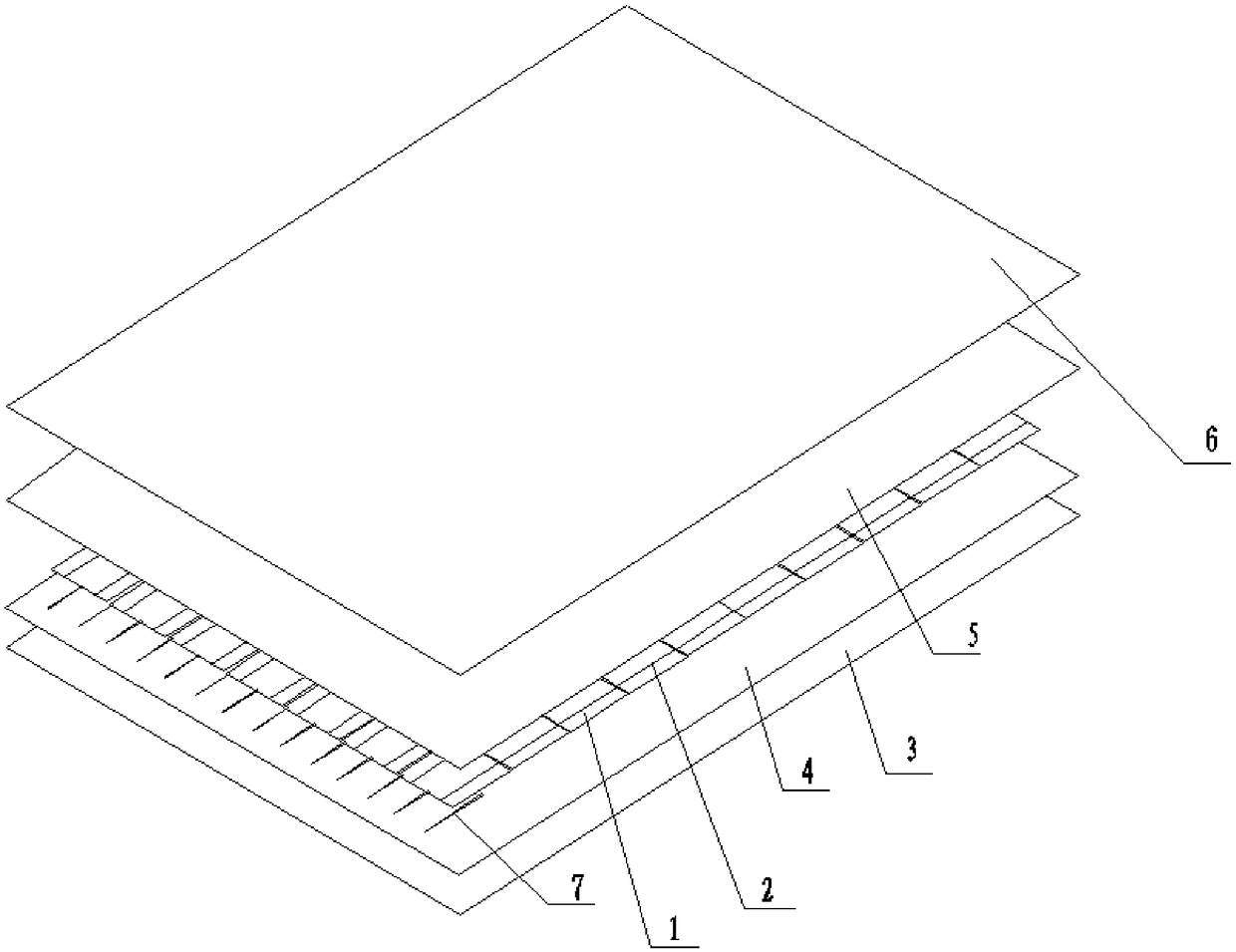

[0030] Such as figure 1 and figure 2 As shown, the conventional packaging process of ordinary black photovoltaic modules is:

[0031] First, a plurality of photovoltaic cells 1 are welded in series to form a battery string with a series connection strip 2 (such as a tinned copper strip);

[0032] Then lay the glass 3 flat on the production line, and the glass is used for the front protection of the photovoltaic module; lay the EVA material on the glass 3 as the laminating glue 4;

[0033] Next, face the front of each battery string to the glass 3 for typesetting, and arrange each battery string in parallel, leaving a gap of 2 to 3 mm wide between the strings; use bus bars to connect the strings of the battery string 3 to each other by welding;

[0034] Lamination adhesive 5 is then laid on the back of all battery strings after typesetting; the lamination ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com