Novel linear motor

A linear motor and a new type of technology, applied in the field of motors, can solve the problems affecting the overall performance of the motor, poor motor vibration effect, unreasonable design, etc., and achieve the effect of improving the service life and application range, increasing the amount of vibration, and having a good vibration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

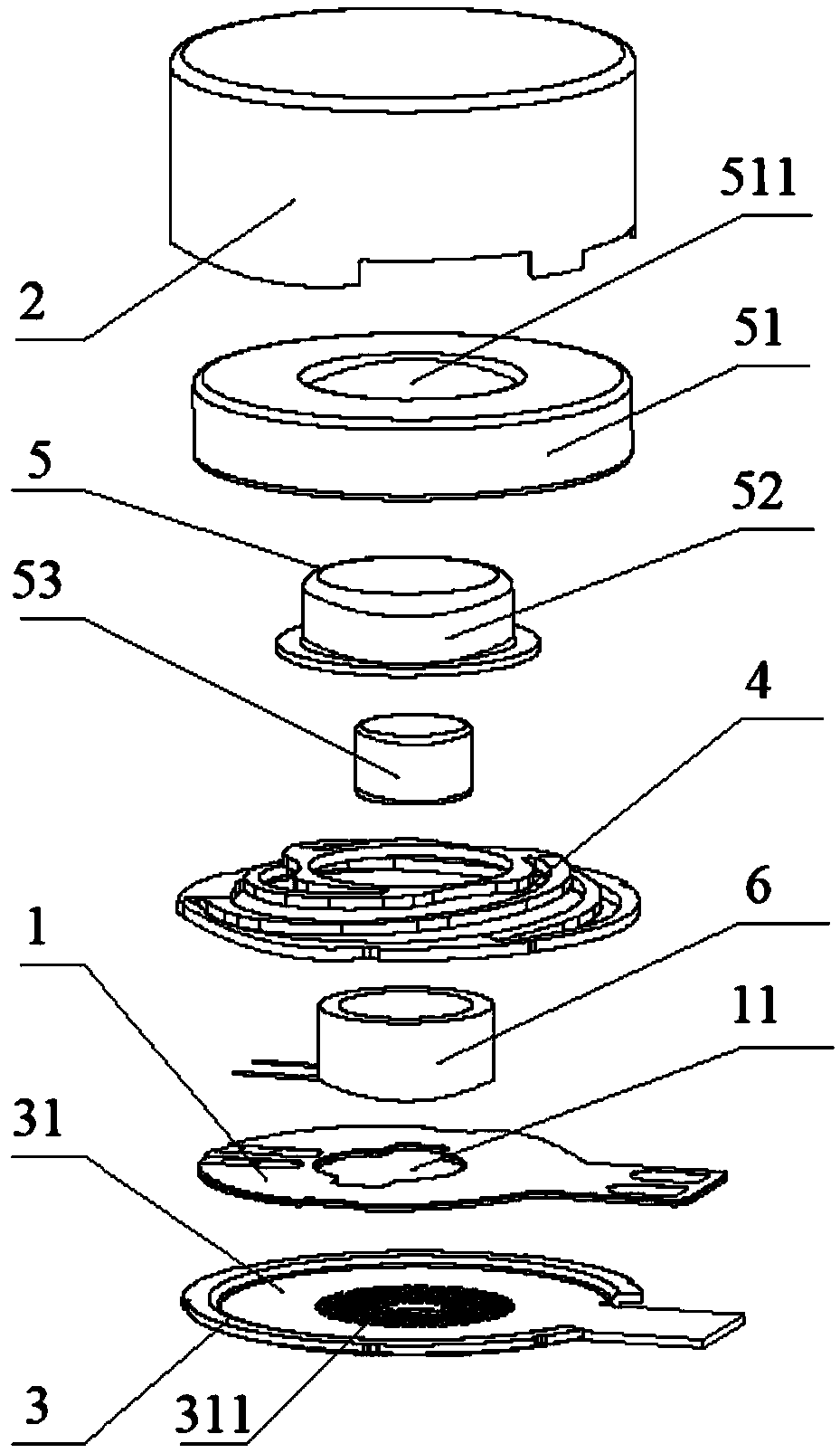

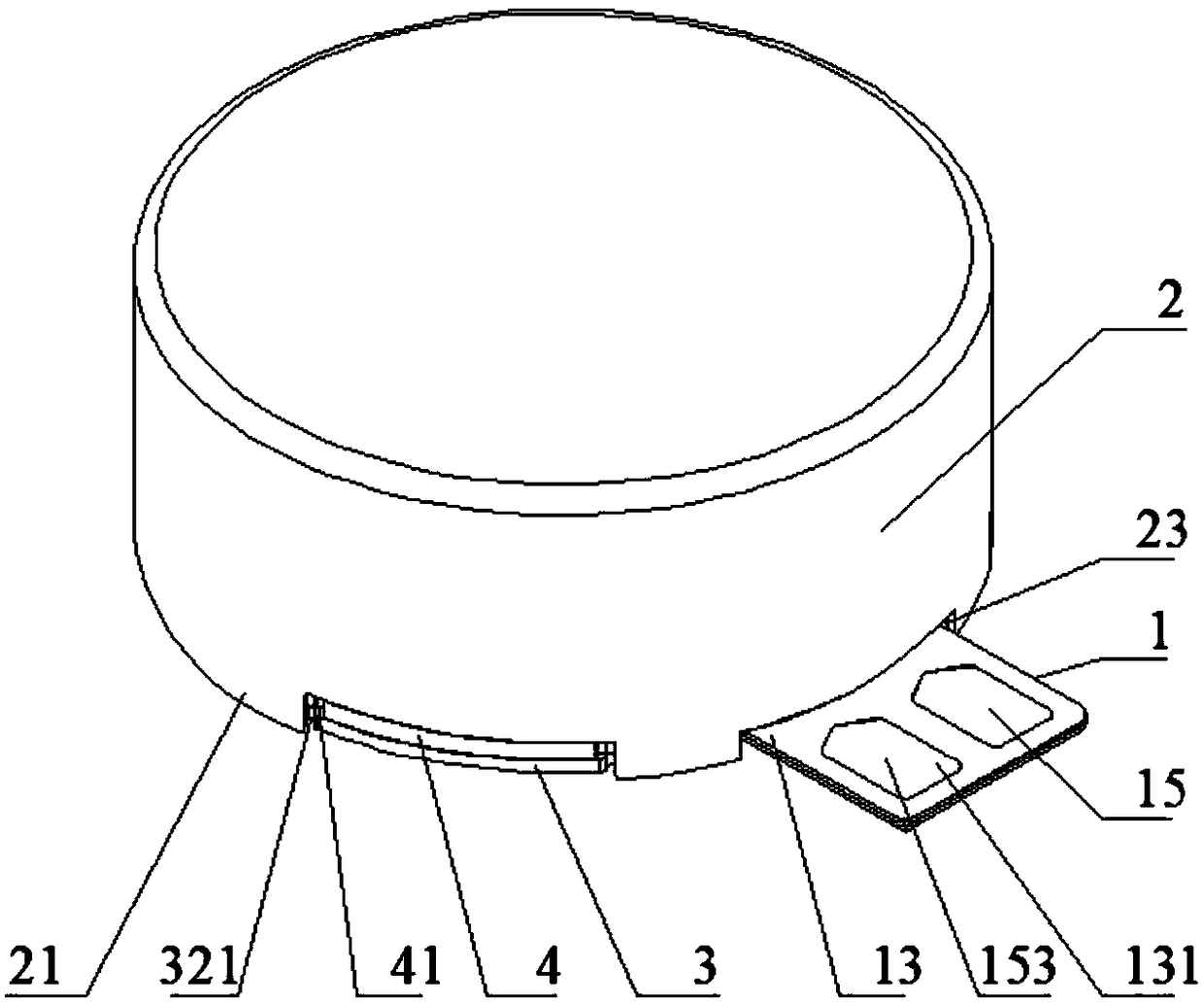

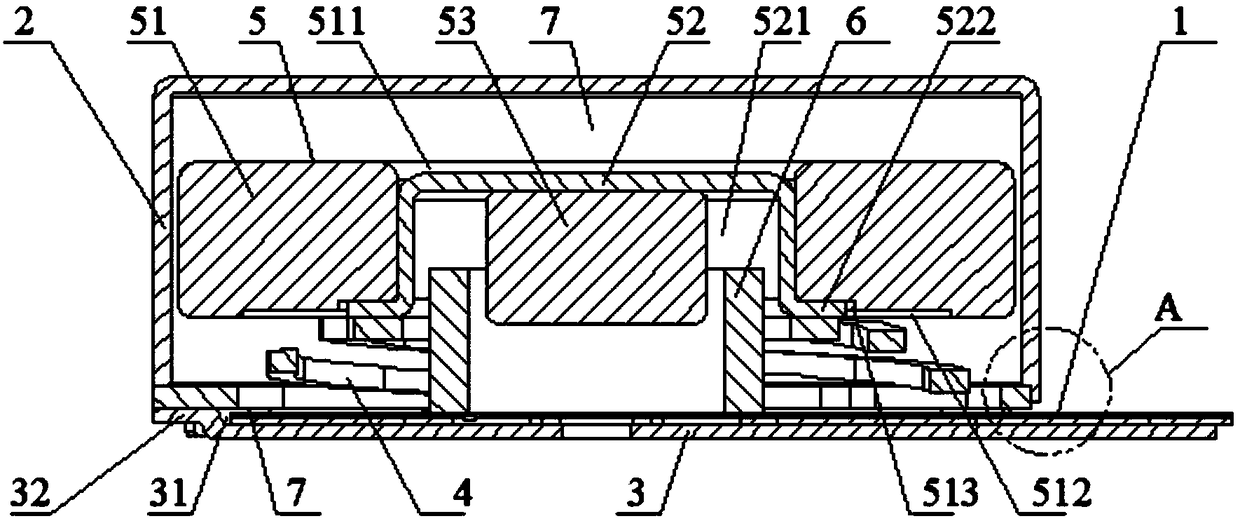

[0034] A new type of linear motor, such as Figure 1-12 As shown, it includes an upper casing 2 and a lower casing 3, and the upper casing 2 and the lower casing 3 are provided with a spring 4, a moving subassembly 5, a coil 6 and an FPC board 1, and the spring 4 is located between the lower casing 3 and the moving Between the subassemblies 5, the mover subassembly 5 includes a balance weight 51, a magnetic yoke 52 and a magnet 53. The balance weight 51 is provided with a first through hole 511 for placing the magnetic yoke 52, and the magnetic yoke 52 is provided with a downward opening. The first groove body 521, one end of the magnet 53 is fixed in the first groove body 521, the lower end of the yoke 52 is provided with the first flange edge 522 that matches with the spring 4, and the upper end of the spring 4 is connected with the first flange edge 522. Stitch welding connection, the lower machine cover 3 is provided with a second groove body 31 for placing the FPC board 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com