Device for harvesting artificially cultured kelp

A kind of kelp and artificial technology, which is applied in the direction of harvesters, agricultural machinery and implements, etc., can solve the problems of large manpower consumption and slow harvesting speed of kelp, and achieve the effect of smooth cutting mouth and smooth cutting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

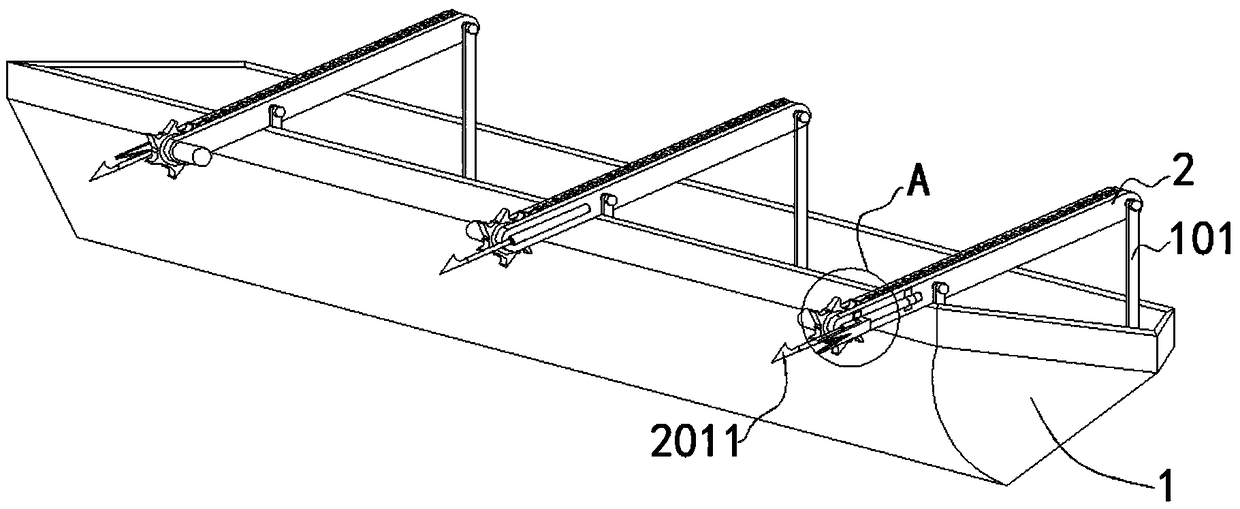

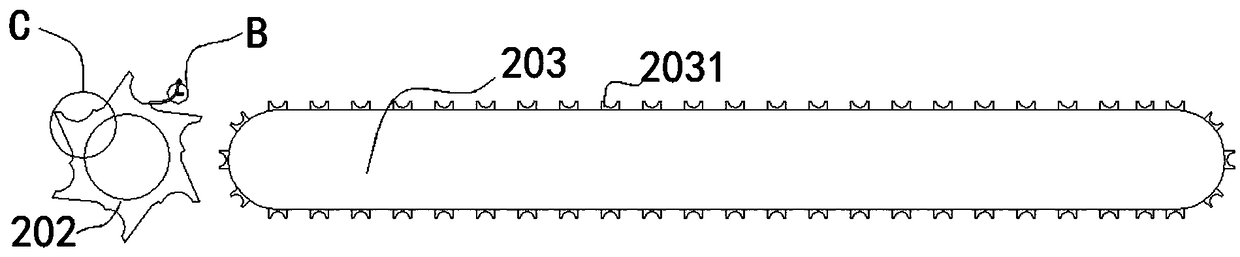

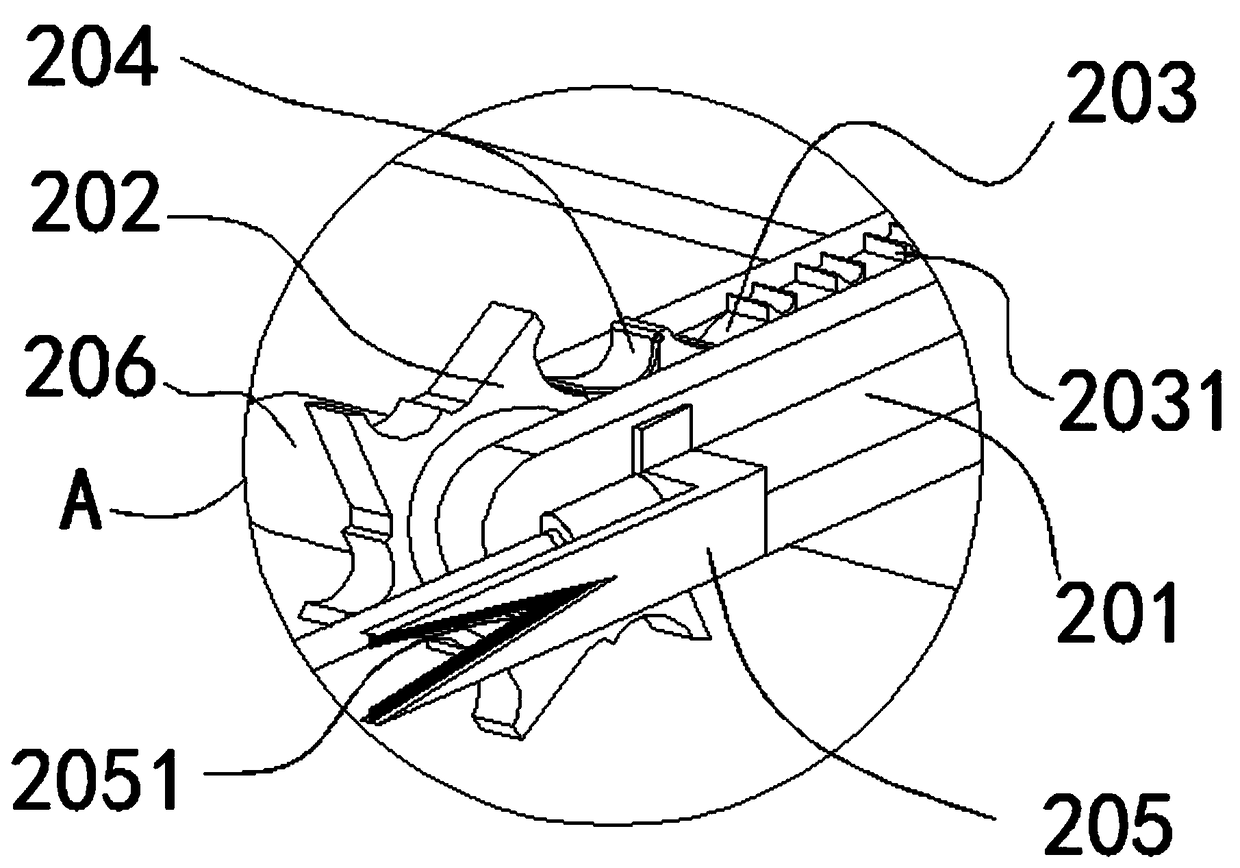

[0027] see Figures 1 to 6 , in an embodiment of the present invention, a device for harvesting artificially cultivated kelp includes a hull 1, a bracket 101, a transmitter 2, a hydraulic rod 201, a barb head 2011, a gear 202, a conveyor belt 203, a fixed block 2031, and a movable guide plate 204 , spring 2041, shear plate 205, cutter head 2051 and motor 206, brackets 101 are fixedly connected to the left and right sides of the inside of the hull 1, the upper end of the hull 1 is fixedly connected to the transmitter 2 through the bracket 101, and the surface of one side of the transmitter 2 is fixedly connected to Hydraulic rod 201, the end of one side of the bottom of hydraulic rod 201 is fixedly connected with barb head 2011, one side of conveyor 2 is internally connected with gear 202, the internal rotation of conveyor 2 is connected with conveyor belt 203, and the outer surface of conveyor belt 203 is fixedly connected with conveyor belt 203 , the top surface of the convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com