Extraction separation device and system thereof and extraction separation method

A separation device and filter cartridge technology, which is applied in the field of extracting and separating effective pharmaceutical ingredients, resins, and rubbers, can solve the problems of extract residues clogging meshes, blocking meshes, and low efficiency, so as to reduce solution residues, reduce residue clogging, and drain smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] Below in conjunction with accompanying drawing, the present invention is described in further detail:

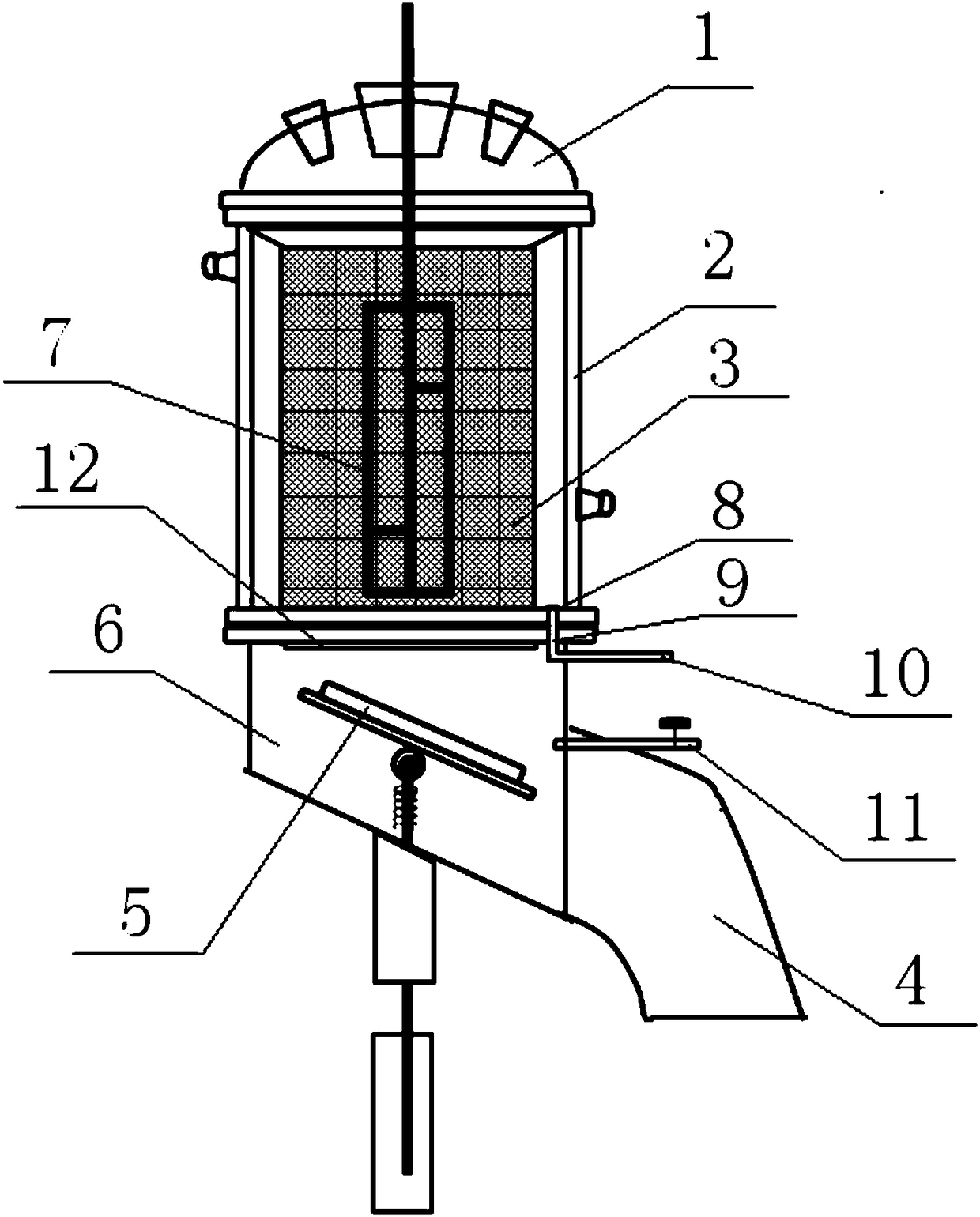

[0072] Such as figure 1 As shown, the device of the present invention includes three parts: from top to bottom are the kettle body head 1, the kettle body and the slag discharge bin; the kettle body head is connected to the upper end of the kettle body through a flange, and the slag discharge bin Connect with the lower end of the kettle body through the flange. The kettle body adopts a jacket design.

[0073] The specific structure of the extraction and separation device of the present invention is as follows:

[0074] The kettle body head 1 and the shell 2 can be made of any material that can be used as the kettle body head in the prior art, preferably stainless steel, enamel, and glass.

[0075] The head of the kettle body 1 is provided with a charging port, a stirring port and a spare port, etc., and a thermometer, a pressure reducing valve or other control and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com