Tool changing processing method of big cutters and small cutters in machining center

A processing center and processing method technology, applied to metal processing equipment, metal processing machine parts, manufacturing tools, etc., can solve problems such as long time and reduced processing efficiency, and achieve reasonable method design, good use effect, and improved efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

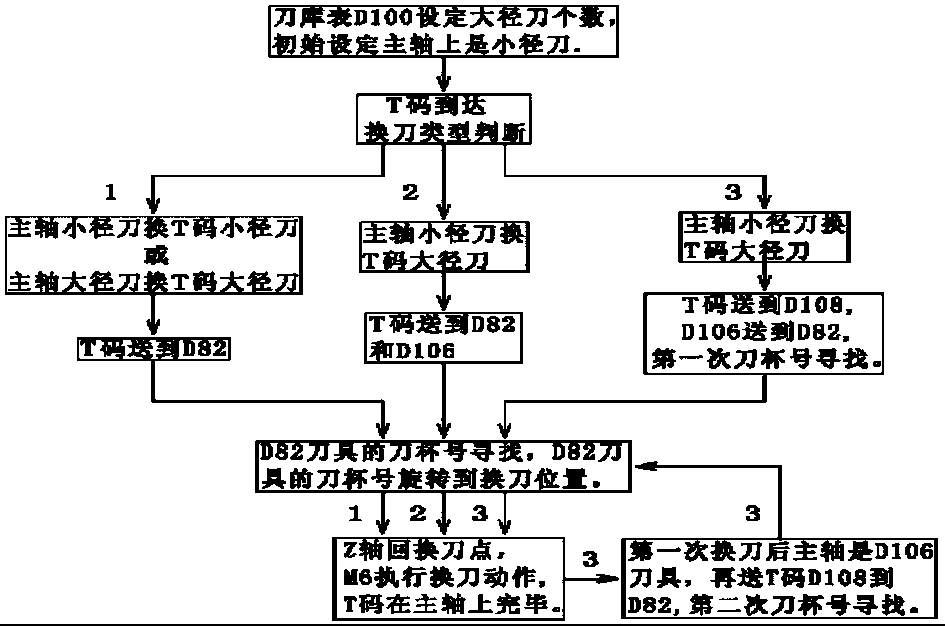

[0022] A tool change processing method for large and small knives in a machining center, the specific steps are as follows:

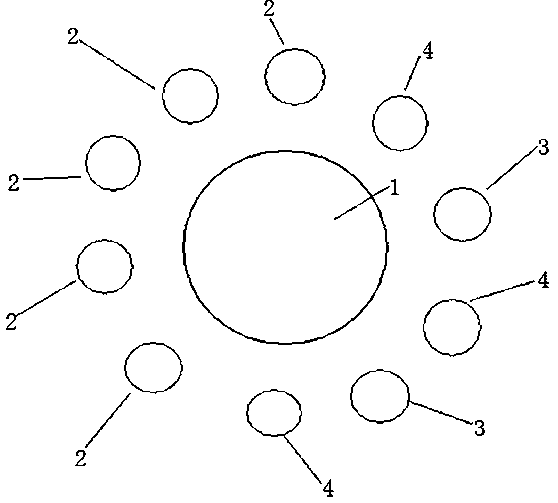

[0023] Step 1: Set the number of large knives and small knives in the tool magazine. The adjacent sides of the large knives in the tool magazine must be empty. The diameter of the large knife should not exceed twice the maximum diameter of the small knives. The number of small knives in the tool magazine must be greater than the number of large knives. Twice and add one more, to judge whether the spindle is a large tool or a small tool, and judge whether the tool pocket where the target tool T0 is located is in the large tool pocket area or in the small tool pocket area;

[0024] Step 2: If the main shaft is a small tool, T0 is located in the area of the small tool pocket, and the tool is changed directly; if the main shaft is a large knife, T0 is located in the area of the large tool pocket, and the tool is changed directly; Change the small tool i...

Embodiment 2

[0026] A tool change processing method for large and small knives in a machining center, the specific steps are as follows:

[0027] Step 1. Set the number of large tools and small tools in the tool magazine. Large tools must be placed in the area of large tool pockets in the tool magazine, and small tools must be placed in the area of large tool pockets or small tool pockets. The initially set spindle tools must be non-large tools. Pre-select Tool processing, judging whether the spindle is a large knife or a small knife, and judging whether the tool pocket where the target tool T0 is located is in the large tool pocket area or in the small tool pocket area;

[0028] Step 2: If the main shaft is a small tool, T0 is located in the area of the small tool pocket, and the tool is changed directly; if the main shaft is a large knife, T0 is located in the area of the large tool pocket, and the tool is changed directly; Change the small tool in the sleeve area to the main s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com