600MPa-grade hot rolled TRIP(transformation-induced plasticity)-type double-phase steel and preparation method thereof

A dual-phase steel and main body technology, applied in the field of hot-rolled advanced high-strength steel for automobiles, can solve problems such as difficult forming and difficult to meet, and achieve the effects of improving safety factor, good economic applicability and application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The second aspect of the present invention provides a method for preparing the above-mentioned 600MPa grade hot-rolled TRIP type dual-phase steel, the steps comprising:

[0027] S1. Hot metal smelting and casting to obtain a billet meeting the chemical composition requirements, heating the billet to 1150-1250°C under the protection of 99.99% high-purity nitrogen and keeping it warm for 1.5-2.5 hours;

[0028] S2. Controlled hot rolling of the slab after heat preservation, the controlled hot rolling includes 2-3 passes of rough rolling and 3-5 passes of finish rolling, and the total reduction of the rough rolling is 82-84%. The finish rolling is rolled at a constant speed of 7-8m / s, the total reduction of the finish rolling is 75-82%, and a hot-rolled steel strip with a thickness of 4.3-4.7mm is obtained;

[0029] S3, cooling the hot-rolled steel strip to 690-720°C at a cooling rate of 40-55°C / s, then air cooling for 20-30s, and then cooling to 250-280°C at a cooling rat...

Embodiment 1

[0032] This embodiment provides a method for preparing a 600MPa grade hot-rolled TRIP type dual-phase steel, the steps comprising:

[0033] The slab is heated to 1200° C. for 2 hours under the protection of 99.99% high-purity nitrogen, and 99.99% of purity nitrogen is used for protection during heating. The chemical composition of the slab is as follows: by mass percentage, C: 0.124%, Si: 0.39%, Mn: 1.67%, Alt: 0.42%, P: 0.014%, and the rest is Fe and unavoidable impurities.

[0034] The slab after heating and heat preservation is started to be hot-rolled at 1180° C. The hot-rolling process is controlled as follows: 3 passes of rough rolling, the total reduction of rough rolling is 83%, and then 4 passes of finish rolling. Rolling at a constant speed of 7.5m / s, the entrance temperature of the final pass of finishing rolling is 880°C, and the total reduction of finishing rolling is 79%, to obtain a hot-rolled steel strip with a thickness of 4.5mm;

[0035] The obtained hot-rol...

Embodiment 2

[0039] This example provides a 600MPa grade hot-rolled TRIP dual-phase steel, using the same preparation steps as Example 1, the difference is that the chemical composition of the slab is: by mass percentage, C: 0.131%, Si : 0.36%, Mn: 1.55%, Alt: 0.45%, P: 0.012%, and the rest are Fe and unavoidable impurities.

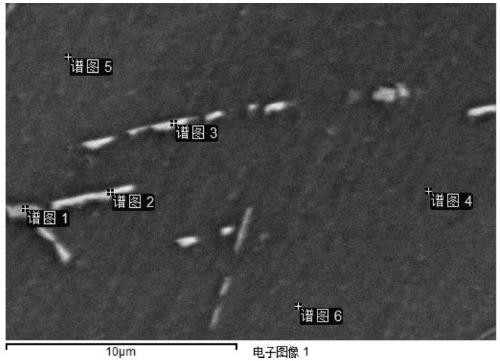

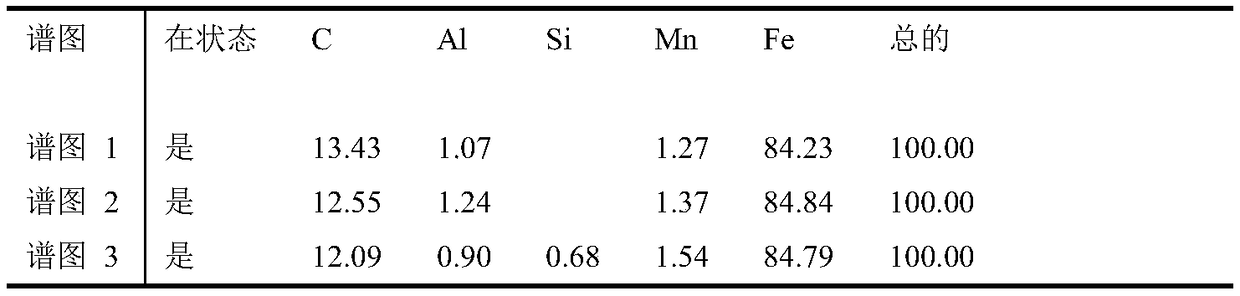

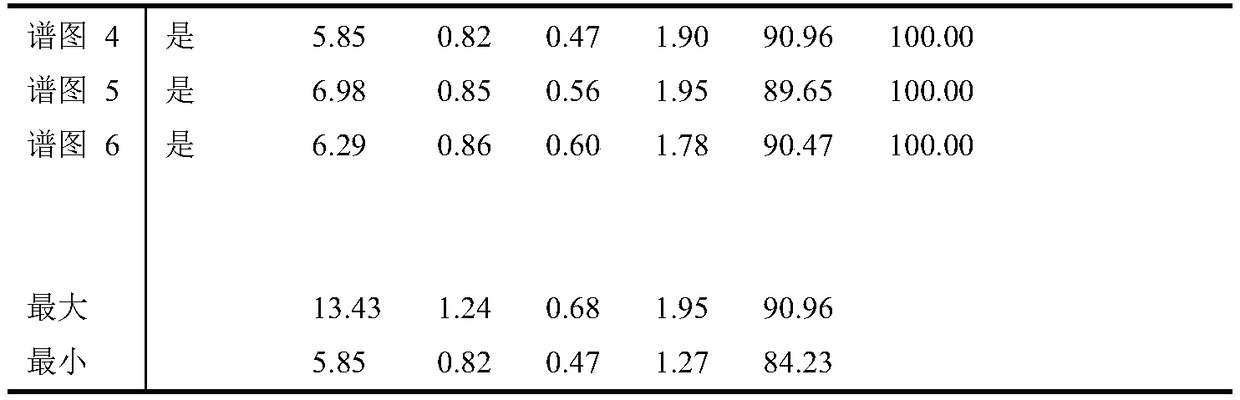

[0040] The microstructure of the obtained 600MPa grade hot-rolled TRIP type dual-phase steel consists of three phases: ferrite, martensite and film-like retained austenite. The percentages of each phase in the surface structure (volume percentage, %) are: 5.2% retained austenite, 11% martensite, the rest are ferrite, and there are rod-shaped carbides in the ferrite. The percentage of each phase of the main structure of the steel except the surface structure is: 3.5% retained austenite, 38% martensite, the rest is ferrite, no carbide precipitation; within the thickness range of 0-22μm from the surface , the average number of rod-shaped carbides per 1000 square micron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com