Polyimide fiber heat treatment method and heat treatment device

A technology of polyimide fiber and heat treatment method, applied in chemical post-treatment of synthetic polymer rayon filament, chemical characteristics of fiber, single-component synthetic polymer rayon, etc., can solve the problem of large thermal shock load and poor fiber performance , poor temperature uniformity, etc., to achieve the effect of good thermal stability, high monofilament strength and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

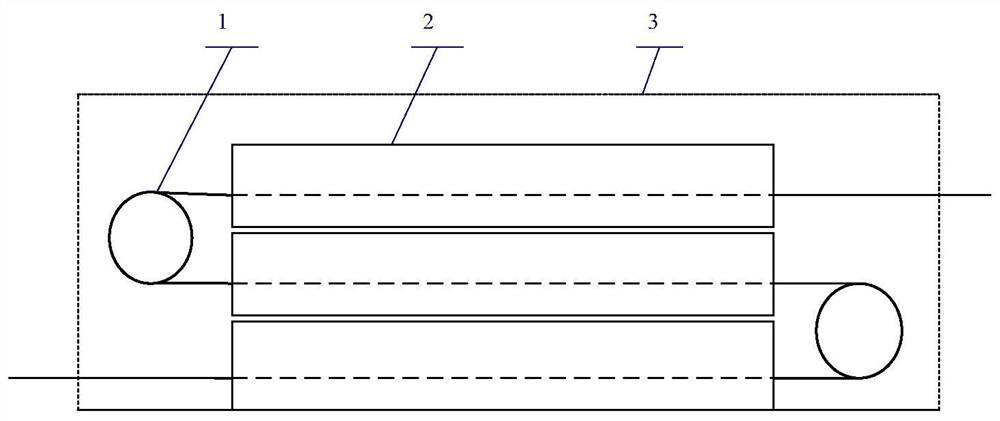

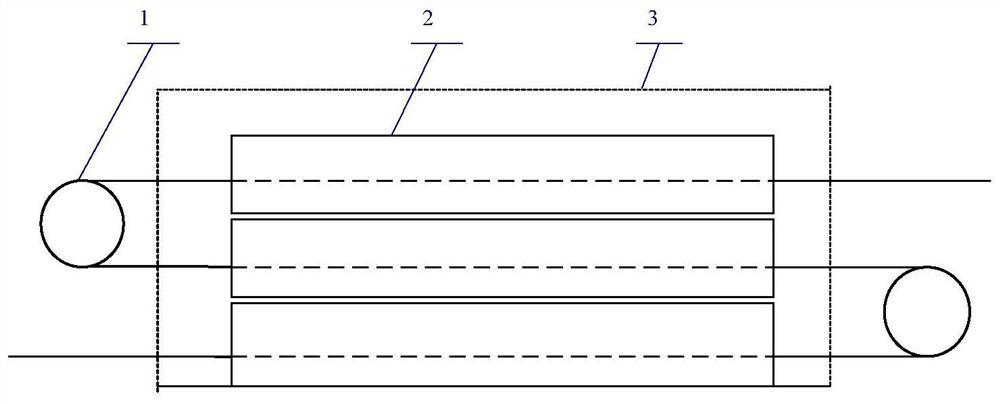

Image

Examples

Embodiment 1

[0026] The PAA primary fiber is placed on the wire feeder, and enters the stacked hot furnace at a speed of 10m / min for imidization treatment. The imidization process adopts the method of gradually increasing the temperature. The furnace has a length of 3m and a total of 5 floors. The first layer is 120°C, the second layer is 180°C, the third layer is 260°C, the fourth layer is 350°C, the fifth layer is 450°C, and the temperature uniformity is ±5°C. Nitrogen protection is used during the imidization process, and the oxygen content is not more than 100ppm.

[0027] Among them, the diameter of the heat roller is 80mm, and the surface temperature from low to high is 120°C, 180°C, 260°C, and 350°C, respectively, and the heat roll is also in a nitrogen environment. Each group of drafting rollers has an independent motor, and the fiber speed is 6m / min. A certain multiple of drafting is achieved through the speed difference between the front and rear drafting machines. The drafting ...

Embodiment 2

[0031] Put the PAA fiber on the wire feeder, and enter the stacked hot furnace at a speed of 30m / min for imidization treatment. The imidization process adopts a gradual temperature increase method. The furnace has a length of 6m and a total of 5 floors. The first layer is 120°C, the second layer is 180°C, the third layer is 260°C, the fourth layer is 350°C, the fifth layer is 450°C, and the temperature uniformity is ±5°C. Nitrogen protection is used during the imidization process, and the oxygen content is not more than 100ppm.

[0032] Among them, the diameter of the heat roller is 80mm, and the surface temperature from low to high is 120°C, 180°C, 260°C, and 350°C, respectively, and the heat roll is also in a nitrogen environment. Each group of drafting rollers has an independent motor, and the fiber speed is 6m / min. A certain multiple of drafting is achieved through the speed difference between the front and rear drafting machines. The drafting ratios from the first layer ...

Embodiment 3

[0035] Put the PAA fiber on the wire feeder and enter the stacked hot furnace at a speed of 50m / min for imidization treatment. The imidization process adopts a gradual temperature increase method. The furnace has a length of 10m and a total of 5 floors. The first layer is 120°C, the second layer is 180°C, the third layer is 260°C, the fourth layer is 350°C, the fifth layer is 500°C, and the temperature uniformity is ±5°C. Nitrogen protection is used during the imidization process, and the oxygen content is not more than 100ppm.

[0036] Among them, the diameter of the hot roller is 300mm, the surface temperature is 120°C, 180°C, 260°C, and 350°C from low to high, respectively, and the hot roller is also in a nitrogen environment. Each group of drafting rollers has an independent motor, and the fiber speed is 6m / min. A certain multiple of drafting is achieved through the speed difference between the front and rear drafting machines. The drafting ratios from the first layer to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com