Heat treatment method and heat treatment device of polyimide fiber

A technology of polyimide fiber and heat treatment method, applied in chemical post-treatment of synthetic polymer rayon filament, chemical characteristics of fiber, single-component synthetic polymer rayon, etc., can solve the problem of poor fiber performance, poor temperature uniformity, High thermal shock load and other problems, to achieve the effect of high monofilament strength and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

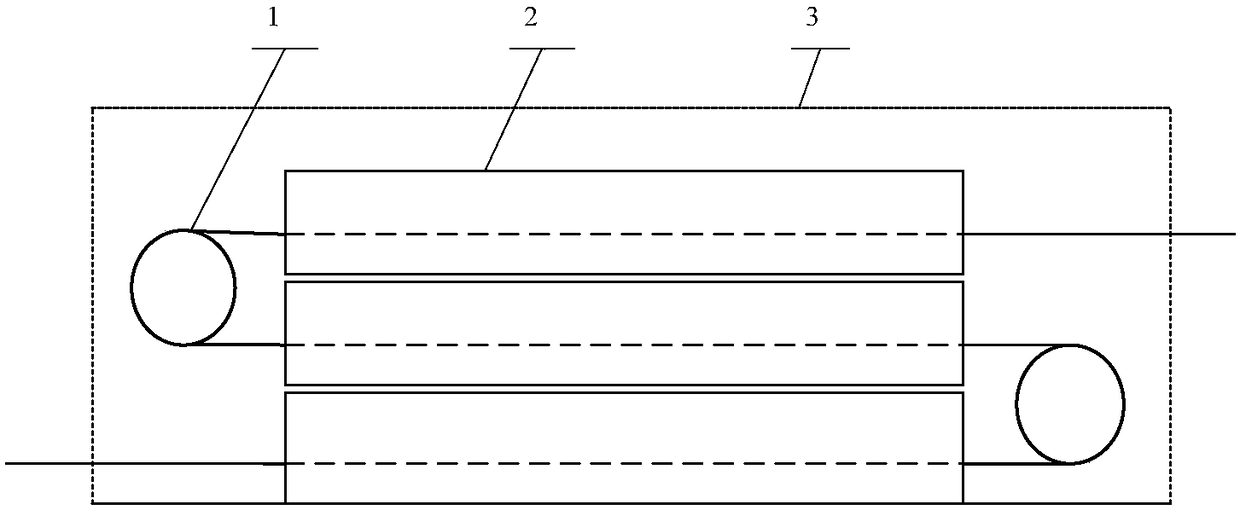

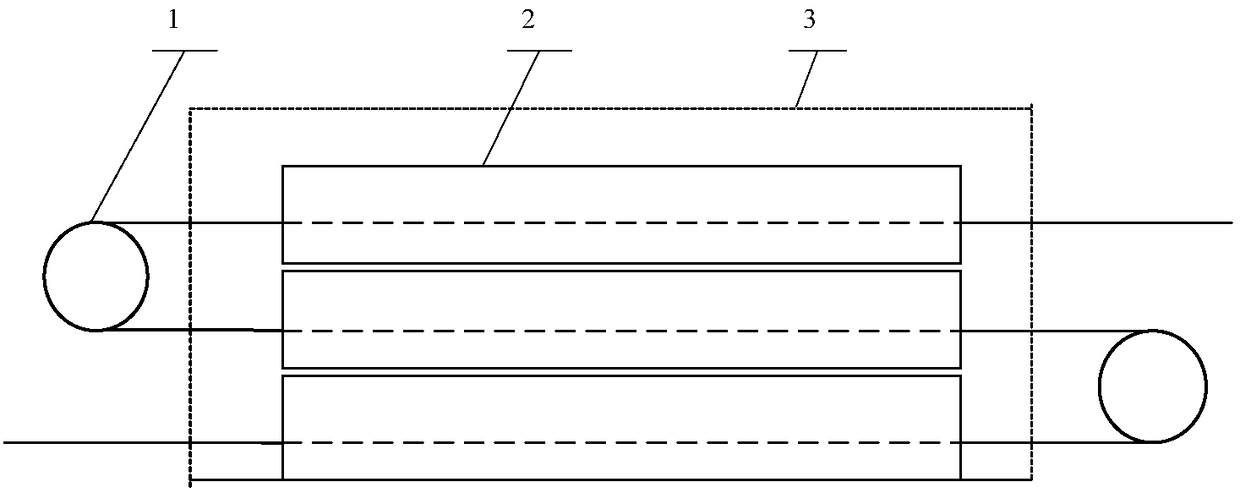

[0026] The PAA primary fiber is placed on the wire feeder, and enters the stacked hot furnace at a speed of 10m / min for imidization treatment. The imidization process adopts the method of gradually increasing the temperature. The furnace has a length of 3m and a total of 5 floors. The first layer is 120°C, the second layer is 180°C, the third layer is 260°C, the fourth layer is 350°C, the fifth layer is 450°C, and the temperature uniformity is ±5°C. Nitrogen protection is used during the imidization process, and the oxygen content is not more than 100ppm.

[0027] Among them, the diameter of the heat roller is 80mm, and the surface temperature from low to high is 120°C, 180°C, 260°C, and 350°C, respectively, and the heat roll is also in a nitrogen environment. Each group of drafting rollers has an independent motor, and the fiber speed is 6m / min. A certain multiple of drafting is achieved through the speed difference between the front and rear drafting machines. The drafting ...

Embodiment 2

[0031] Put the PAA fiber on the wire feeder, and enter the stacked hot furnace at a speed of 30m / min for imidization treatment. The imidization process adopts a gradual temperature increase method. The furnace has a length of 6m and a total of 5 floors. The first layer is 120°C, the second layer is 180°C, the third layer is 260°C, the fourth layer is 350°C, the fifth layer is 450°C, and the temperature uniformity is ±5°C. Nitrogen protection is used during the imidization process, and the oxygen content is not more than 100ppm.

[0032] Among them, the diameter of the heat roller is 80mm, and the surface temperature from low to high is 120°C, 180°C, 260°C, and 350°C, respectively, and the heat roll is also in a nitrogen environment. Each group of drafting rollers has an independent motor, and the fiber speed is 6m / min. A certain multiple of drafting is achieved through the speed difference between the front and rear drafting machines. The drafting ratios from the first layer ...

Embodiment 3

[0035] Put the PAA fiber on the wire feeder and enter the stacked hot furnace at a speed of 50m / min for imidization treatment. The imidization process adopts a gradual temperature increase method. The furnace has a length of 10m and a total of 5 floors. The first layer is 120°C, the second layer is 180°C, the third layer is 260°C, the fourth layer is 350°C, the fifth layer is 500°C, and the temperature uniformity is ±5°C. Nitrogen protection is used during the imidization process, and the oxygen content is not more than 100ppm.

[0036] Among them, the diameter of the hot roller is 300mm, the surface temperature is 120°C, 180°C, 260°C, and 350°C from low to high, respectively, and the hot roller is also in a nitrogen environment. Each group of drafting rollers has an independent motor, and the fiber speed is 6m / min. A certain multiple of drafting is achieved through the speed difference between the front and rear drafting machines. The drafting ratios from the first layer to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com