A construction method of basement exterior wall

A technology of basement exterior wall and construction method, which is applied in the direction of wall, formwork/formwork/work frame, and on-site preparation of building components, etc., can solve the influence of tie-rod eye repair quality exterior wall leakage prevention and the poor integrity of exterior wall concrete It can reduce the hidden danger of water seepage, improve the appearance quality, and improve the waterproof effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

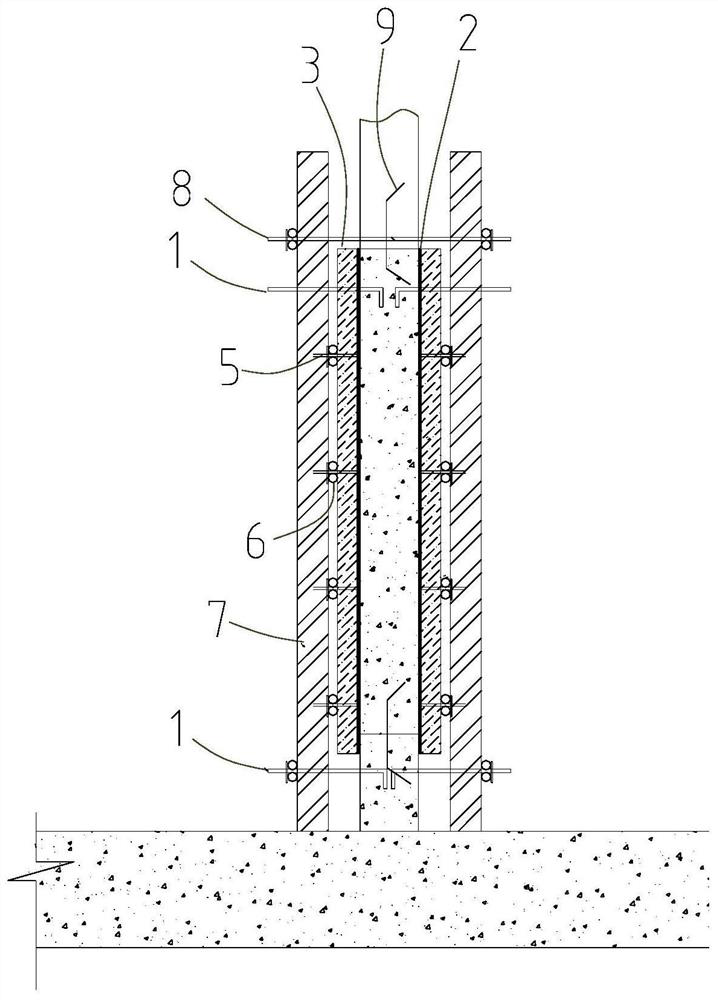

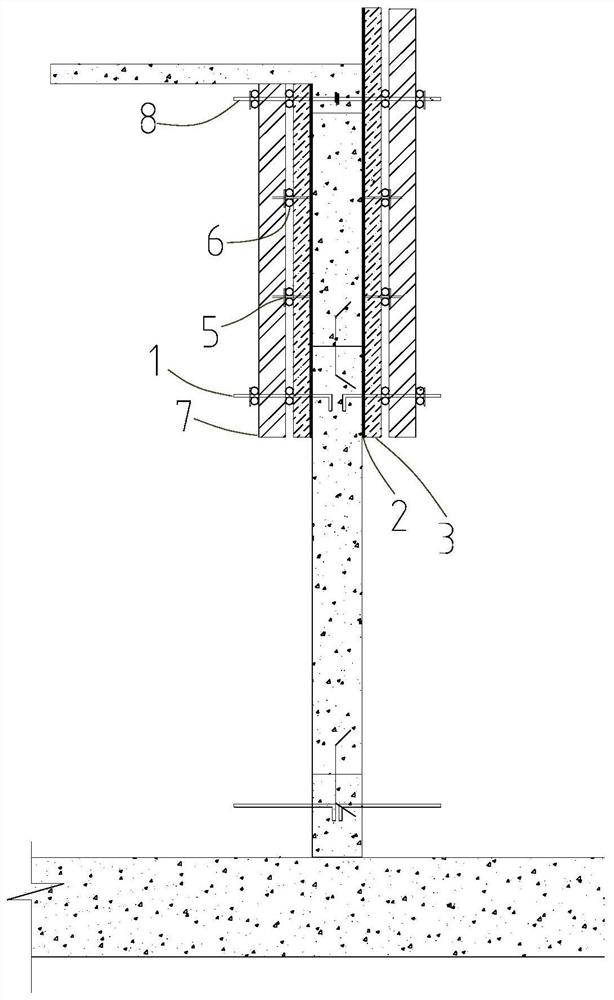

[0018] Combine below Figure 1 to Figure 3 , the present invention is described in further detail.

[0019] A construction method for a basement exterior wall, comprising the steps of:

[0020] S1. Construction of external wall overturning: construction of basement raft, on the bottom slab concrete, set an outer wall overturn with a height of 40cm-50cm, L-shaped tie rod 1 is embedded in the outer wall overturn, and the outer wall overturn is poured together with the bottom slab concrete ;

[0021] S2. Construction of the middle section of the outer wall: after the completion of the overturning construction on the outer wall, install formwork on both sides of the steel skeleton of the outer wall corresponding to the middle section of the outer wall, and pre-embed the L-shaped tie rod 1 at the upper end of the middle section of the outer wall, and then pour concrete to complete the construction of the middle section of the outer wall , the height of the middle section of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com