The construction method of the waterproof cover in the transition area of ptfe membrane roof

A construction method, PTFE technology, applied to roofs, buildings, building components, etc., can solve problems such as high strength requirements for connection parts, poor matching degree, and easy quality hidden dangers, so as to reduce water seepage risks and leakage risks , to avoid the effect of seam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further understand the content of the invention, features and effects of the present invention, the following embodiments are exemplified and described in detail with the accompanying drawings as follows:

[0026] It should be noted that, unless otherwise expressly specified and limited, the terms "first", "second" and the like do not represent sequential installation, nor the importance of the described components.

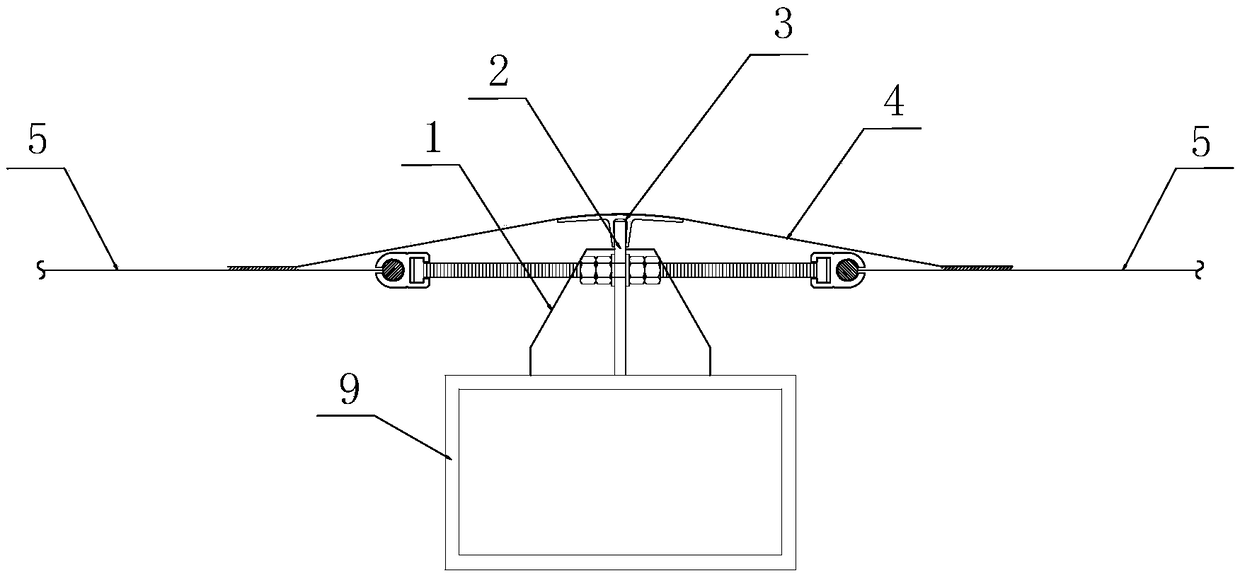

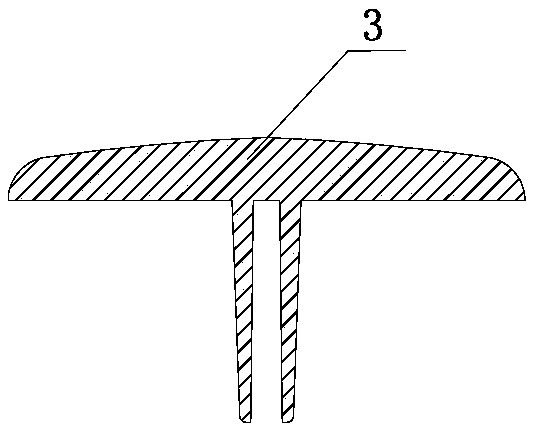

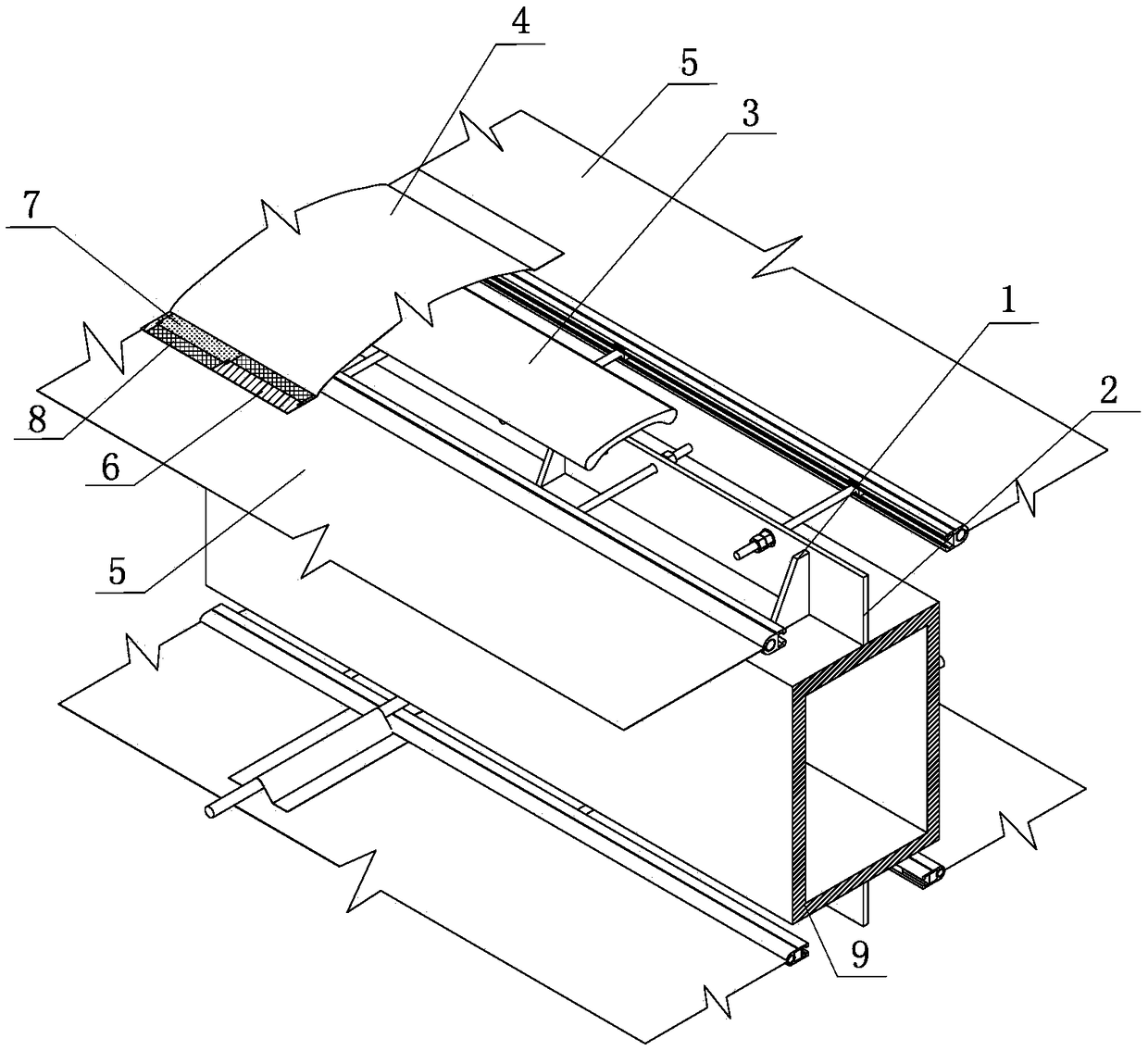

[0027] see Figure 1-Figure 4 , a PTFE membrane roof transition area waterproof cover, including a PTFE cover membrane 4, a connecting membrane plate 2, a stiffener 1 and a membrane cover supporting member 3, and the connecting membrane plate is vertically fixed on the roof of the roof beam 9. A plurality of stiffening ribs are fixed on both sides of the connecting membrane plate, the upper part of the connecting membrane plate is equipped with a membrane cover opening support, and a high-strength fiber PTFE cover opening film is fixed on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com