Assembly type novel material composite wallboard envelope structure system and manufacturing process

A composite wall panel and envelope structure technology, applied in building materials, manufacturing tools, building components, etc., can solve the problems of energy conservation and environmental protection, and achieve the effects of improving product production efficiency, high processing precision, and high degree of prefabrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

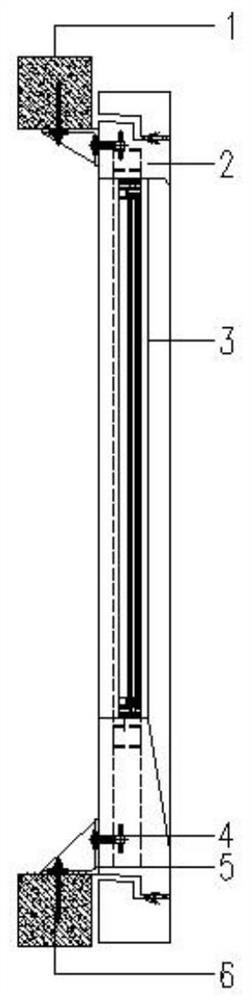

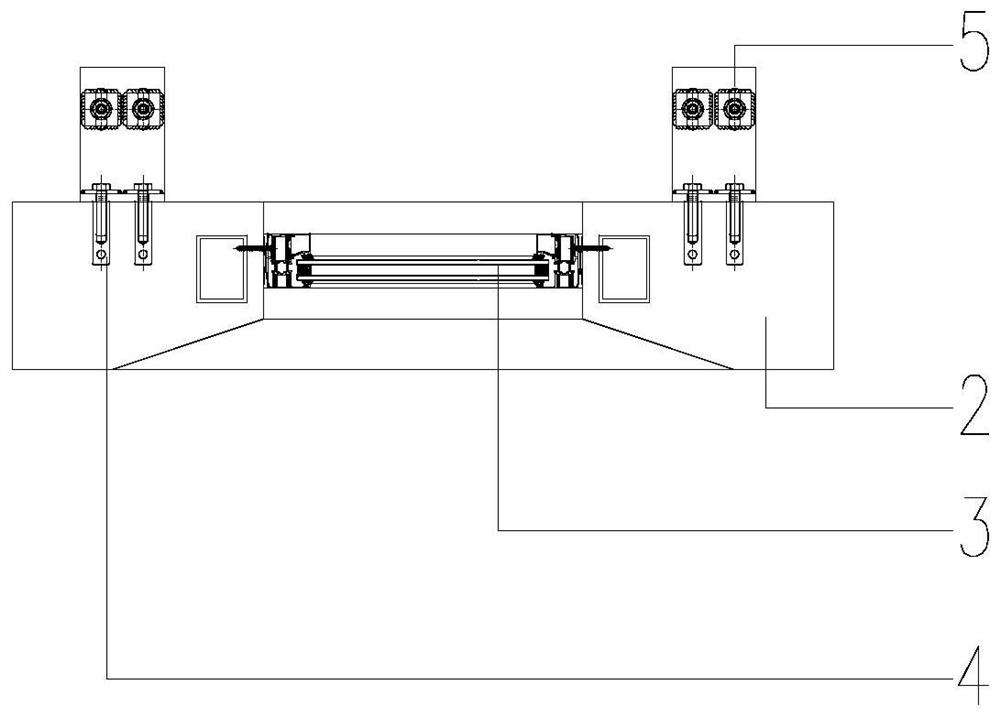

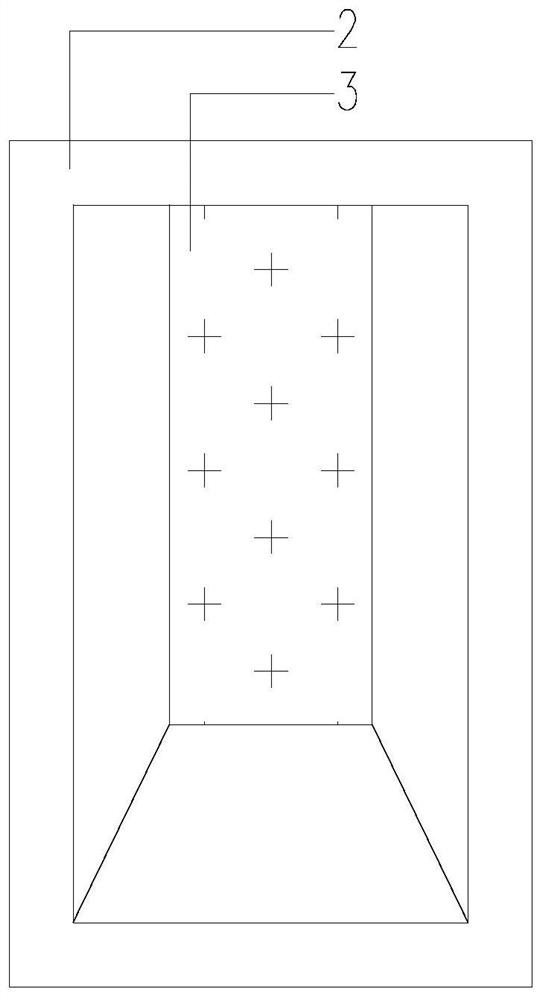

[0035] An assembled new material composite wall panel enclosure structure system, including GRC exterior wall panel 2, the inner hole in the middle of GRC exterior wall panel 2 is installed with broken bridge heat-insulating aluminum alloy doors and windows 3, and the upper and lower ends of GRC exterior wall panel 2 are installed with M12 The sleeve 4 and the M12 sleeve 4 are connected with the 8mm galvanized steel angle code 5 in the main structure 1 at the upper and lower ends with mechanical anchor bolts 6 .

[0036] The manufacturing process of the prefabricated new material composite wall panel enclosure structure is introduced in detail below. First of all, divide the boards as a whole, determine the separation of the unit boards, and carry out the overall design of the unit boards (according to the building facade modeling requirements, such as solid wall shape, size, separation, etc., and building use functions, such as interior layout, structure, Lighting, ventilatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com