Velocity string sand-preventing-type plugging tool and using method thereof

A speed pipe string and sand control technology, which is used in earth-moving drilling, wellbore/well components, sealing/packing, etc., can solve problems such as puncture, hidden danger, and affect the normal production of gas wells, and achieve reliable sealing and convenient sand control. , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

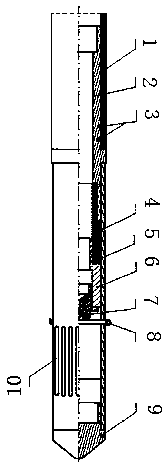

[0023] A speed pipe string sand prevention plugging tool, which at least includes an inner connection pipe 2 connected to the lowermost end of the speed pipe string 1, characterized in that: the inner connection pipe 2 is a pipe column structure, and the lower part of the inner connection pipe 2 is fixed with a guide head 9 , the inner cavity of the inner connection pipe 2 is provided with a plug 7, the plug 7 is fixed by the pin 8 and the inner connection pipe 2, the outer wall of the inner connection pipe 2 is fixed with a sand guard 5 along its circumference, and the side of the inner connection pipe 2 below the plug 7 Air intake slots 10 are provided on the wall and at corresponding positions of the sand control shield 5 .

[0024] like figure 1 As shown, in the production process of water-producing gas wells, in order to reduce the pipe diameter and increase the gas flow rate to help the gas well carry liquid, it is necessary to adopt the velocity pipe string drainage gas...

Embodiment 2

[0027] like figure 1 As shown, it is improved on the basis of Embodiment 1, and the pin 8 is detachably connected with the inner connecting pipe 2 along the diameter direction of the inner connecting pipe 2 . The plug 7 is fixed on the inner connection pipe 2 by the pin 8. At this time, the plug 7 is in a sealed state and plays the role of isolating the gas layer and the velocity string 1; The annulus production of the crude oil pipeline causes a pressure difference between the top and bottom of the plug 7 in the inner cavity of the inner connection pipe 2, so that the pin 8 is cut off and the plug 7 is removed. At this time, the sealing state of the plug 7 is released, and the production pipeline starts the production mode. At this time, the detachable connection mode is convenient for production, saves labor costs, and has high production efficiency.

[0028] The inner connecting pipe 2 is rolled and connected to the lowermost end of the velocity string 1 . The rolling con...

Embodiment 3

[0036] like figure 1 As shown, it is improved on the basis of Embodiment 1 or Embodiment 2, and the bottom end of the guide head 9 is a closed conical structure. The conical structure is more in line with the requirements of the aerodynamic structure for the shape of the product. During the production process of water-producing gas wells, the air resistance is reduced and it is convenient to use.

[0037] There are several air intake slots 10 , and the several air intake slots 10 are uniformly arranged circumferentially along the corresponding positions of the inner connection pipe 2 and the sand protection shield 5 .

[0038]When in use, the high-pressure gas in the gas well casing is introduced into the velocity string 1, and then the velocity string 1 and the crude oil pipe annulus are used to produce a pressure difference between the upper and lower plugs 7 of the inner cavity of the inner connection pipe 2, thereby shearing The pin 8 further removes the plug 7 to form th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com