Rapid drying fan for workshop ground painting

A fast-drying, ground-based technology, applied in the direction of mechanical equipment, pre-treated surfaces, machines/engines, etc., can solve problems such as unfavorable production, short construction period, time-consuming, etc., and achieve the effect of improving drying efficiency and speeding up the working process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

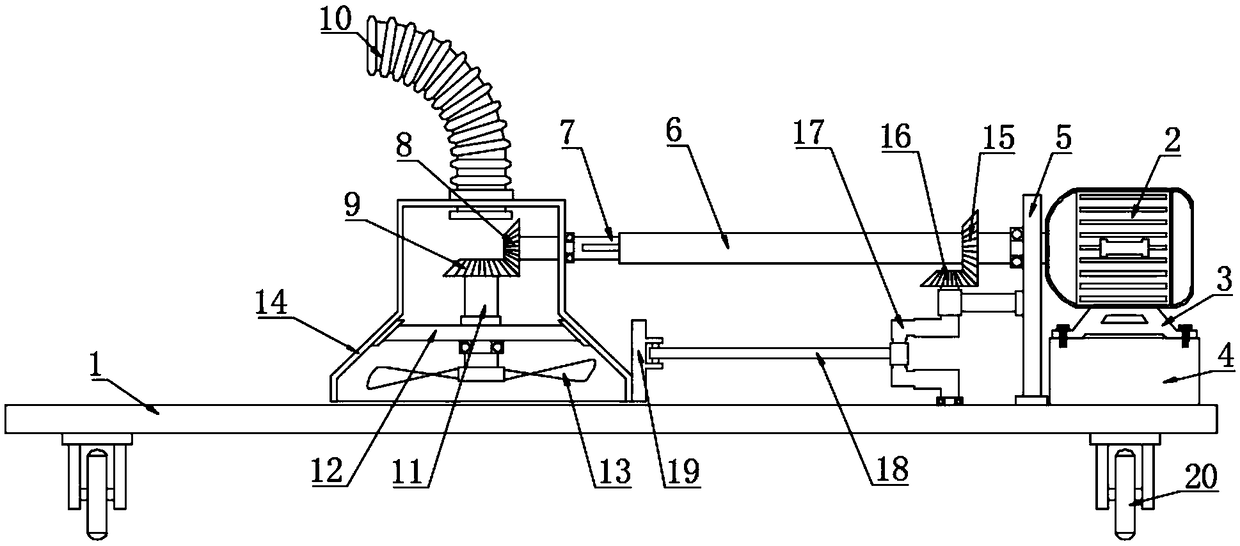

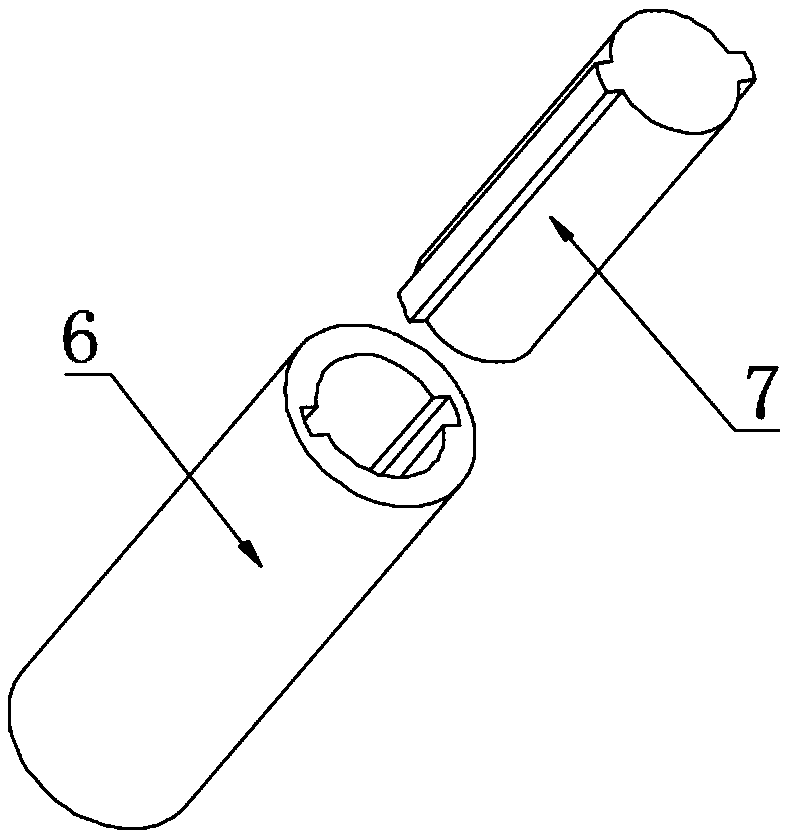

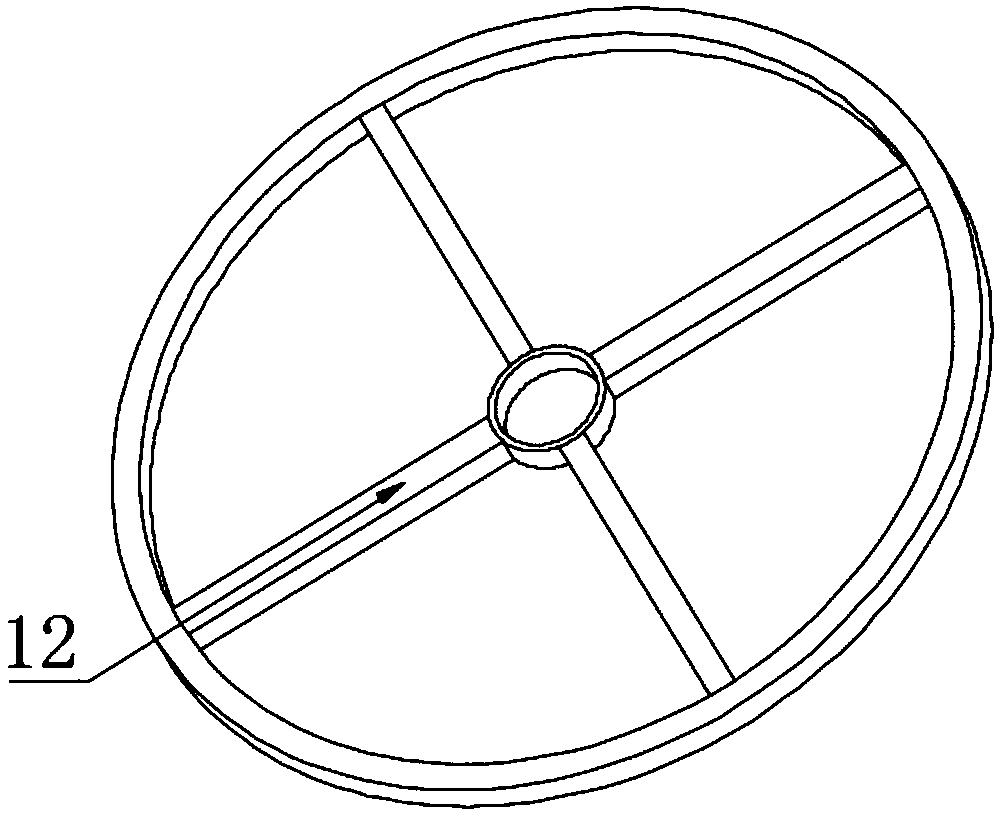

[0020] see Figure 1~3 , in an embodiment of the present invention, a quick-drying fan for painting the floor of a factory building includes a trolley plate 1, an output shaft 6, a driven shaft 7, a fan 13, a crankshaft 17, and a connecting rod 18; the four corners of the lower surface of the trolley plate 1 Both are fixed with a wheel frame, and the wheel frame is connected with the roller 20 through the rotation of a pin shaft. It should be noted that a plurality of through grooves or through holes are provided on the trolley plate 1, and a drive motor 2 is arranged on one side of the trolley plate 1, and the drive motor 2 wires are connected to the power supply and the switch, and the lower part of the drive motor 2 is fixedly connected to the motor base 3, and the lower part of the motor base 3 is fixedly connected to the battery 4 through bolts, wherein the battery 4 is a rechargeable battery, and its rear part has a charging port and an indicator light. The storage batte...

Embodiment 2

[0024] In order to make the technical solutions in this application more detailed and complete, now some supplements and explanations are made on the basis of the above-mentioned embodiment 1, so that the disclosure of the technical means adopted in this application is more sufficient, specifically, the supplements and explanations Part of the technical feature is that the rear of the trolley board 1 is fixedly connected with a handle, the handle is covered with a rubber sleeve, the bearing at the lower part of the handle is rotatably connected to the steering wheel, the steering wheel is rotatably connected to the wheel frame, and the wheel frame bearing is rotatably connected to the lower part of the trolley board 1. On the surface, the trolley board 1 is pushed forward by the handle, so as to realize the function of moving and drying. At the same time, the traveling direction of the trolley board 1 is controlled by the steering wheel connected by rotation, so as to realize th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com