Variable decoupling membrane rigidity mixed mode magnetorheological vibration isolator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

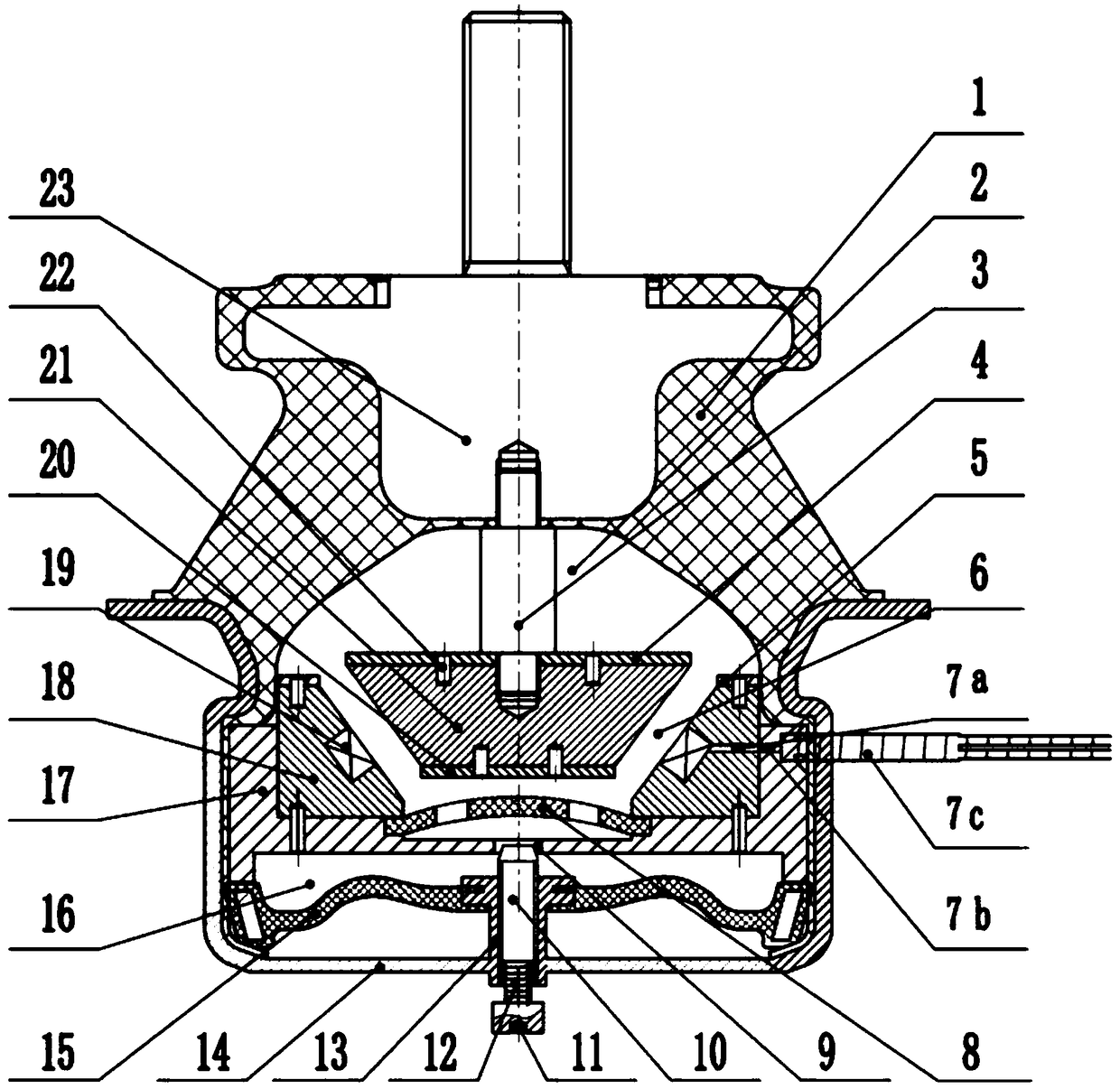

[0024] figure 1 It is a schematic structural diagram of the present invention, including a housing 14 for containing magnetorheological fluid and an open top end, and a main rubber spring 1 sealed at the open end of the housing 14. A rubber bottom film 15 is provided in the housing 14 , A magnetic core assembly and a decoupling membrane assembly, the decoupling membrane assembly includes a decoupling membrane 8 and a base 17, the base 17 is provided with a groove for placing the decoupling membrane 8, and the bottom of the groove is provided with The orifice 9, the decoupling membrane assembly is arranged in the housing 14 and divides the inner cavity of the housing 14 into the upper cavity 2 and the lower cavity 16, the rubber bottom membrane 15 is located in the lower cavity 16, and the magnetic The core assembly is located in the upper cavity 2. The magnetic core assembly includes an outer magnetic core 18, an inner magnetic core 21, an excitation coil 19 arranged on the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com