Sand drying device with anti-return sand kiln head

A kiln head and anti-return technology, applied in the direction of heating devices, drying, dryers, etc., can solve the problems of simple working principle, clogging of dryers, and reduced output, so as to achieve slow convection speed, high work efficiency, Effect of preventing sand return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

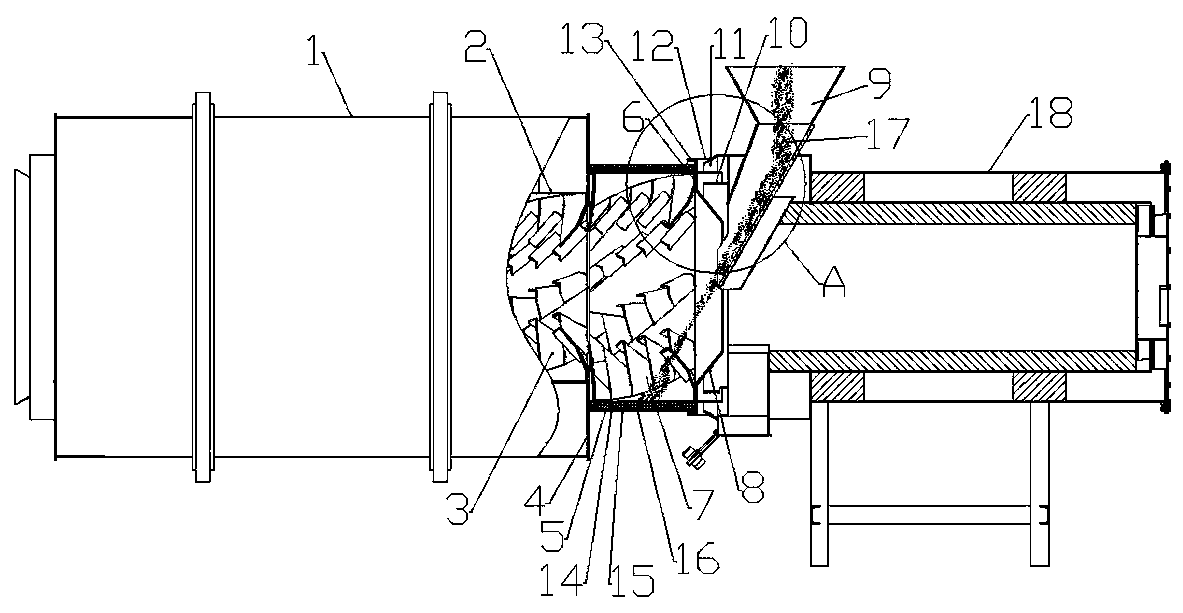

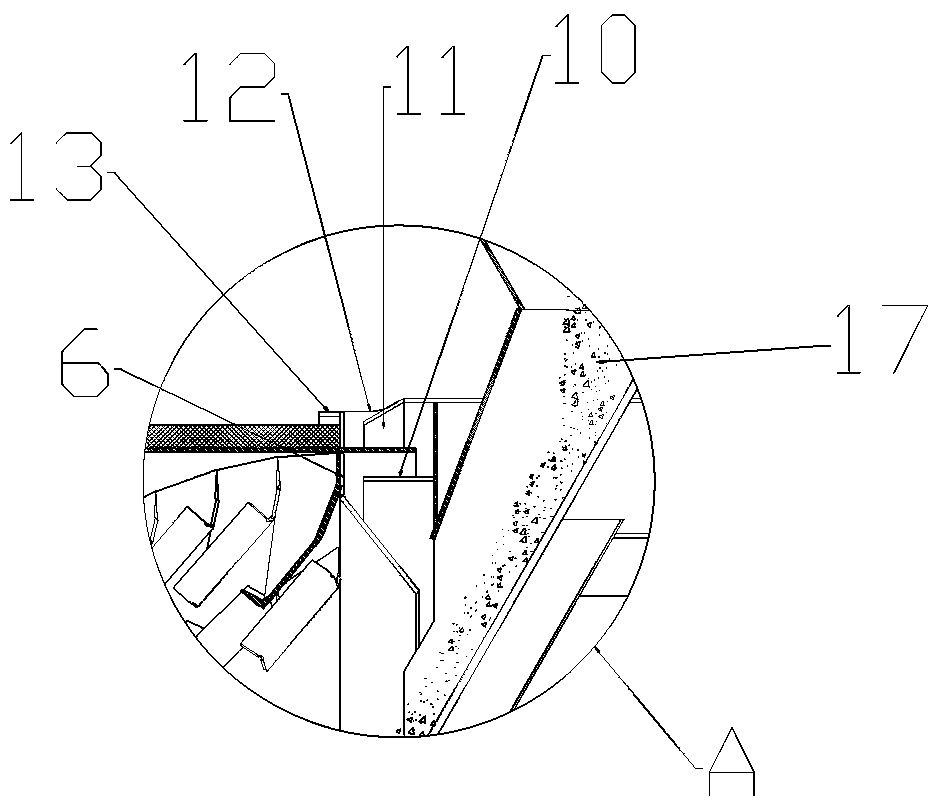

[0020] Embodiment 1: A sand drying device with an anti-sand return kiln head, including a sand drying machine assembly, a kiln head, and a combustion furnace 18. The sand drying machine assembly is connected to the kiln head, and the kiln head is connected to the combustion furnace. The combustion furnace Transfer temperature to the kiln head for sand drying.

[0021] The sand drying machine components include the sand drying machine shell 1, the sand drying machine inner cylinder 2 is installed in the sand drying machine shell, and the inner wall of the sand drying machine inner cylinder is installed with a spiral arrangement of multi-fold curved sand plates Ⅰ 3, the sand drying machine shell There is an inlet sealing plate 4 connected between the port and the port of the inner cylinder of the sand dryer; the kiln head includes a kiln head cylinder 5 that is connected to the inlet sealing plate at one end, and the kiln head cylinder 5 is welded to the inlet sealing plate, ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com