Plasma enhancement type microchip exploding foil initiator and preparation method

A plasma and enhanced technology, applied in blasting barrels, offensive equipment, weapon accessories, etc., can solve the problems of low precision, high manufacturing cost, and reduce the ignition energy of McEFI, and achieve high integration, reduce manufacturing cost, and enhance capabilities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

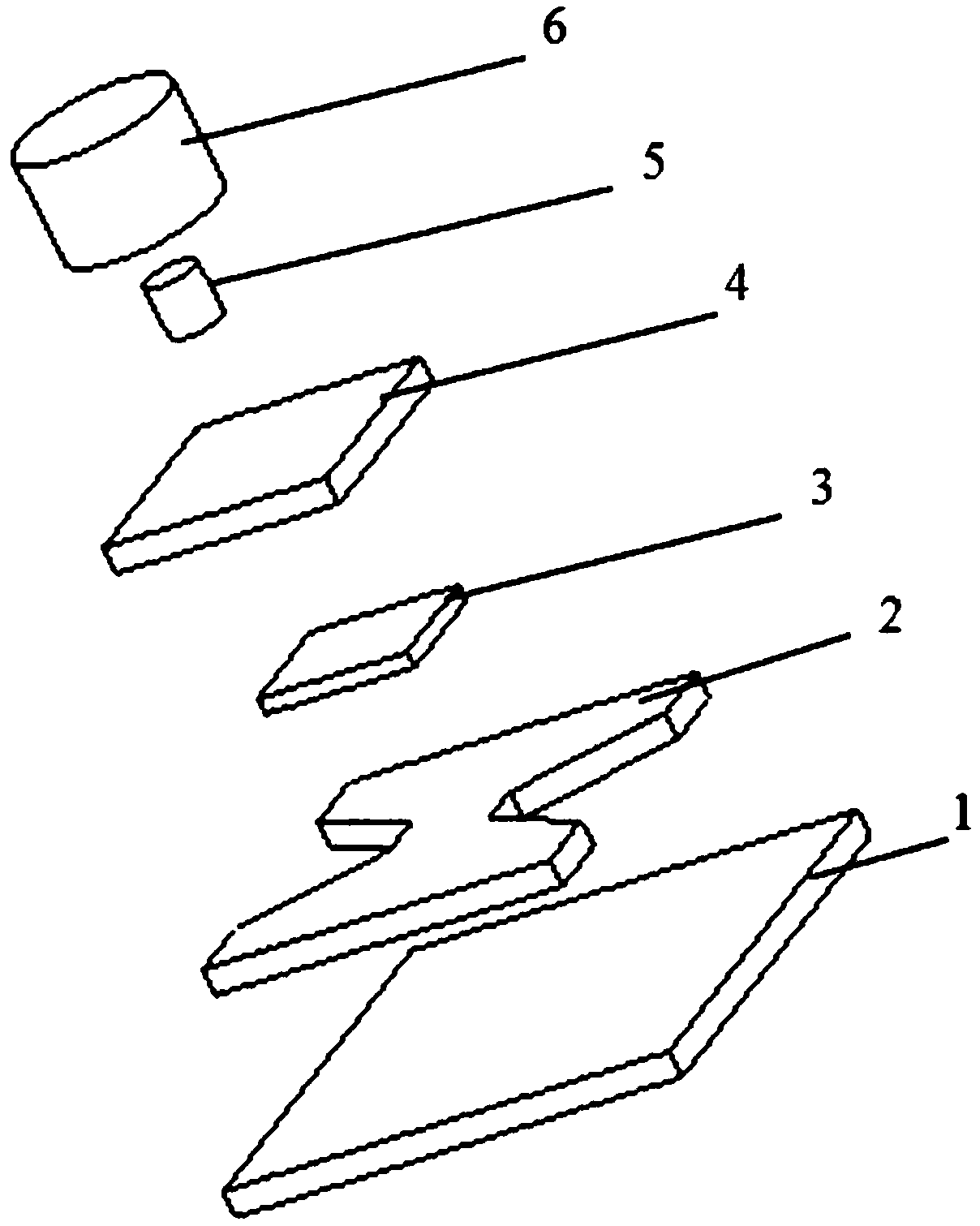

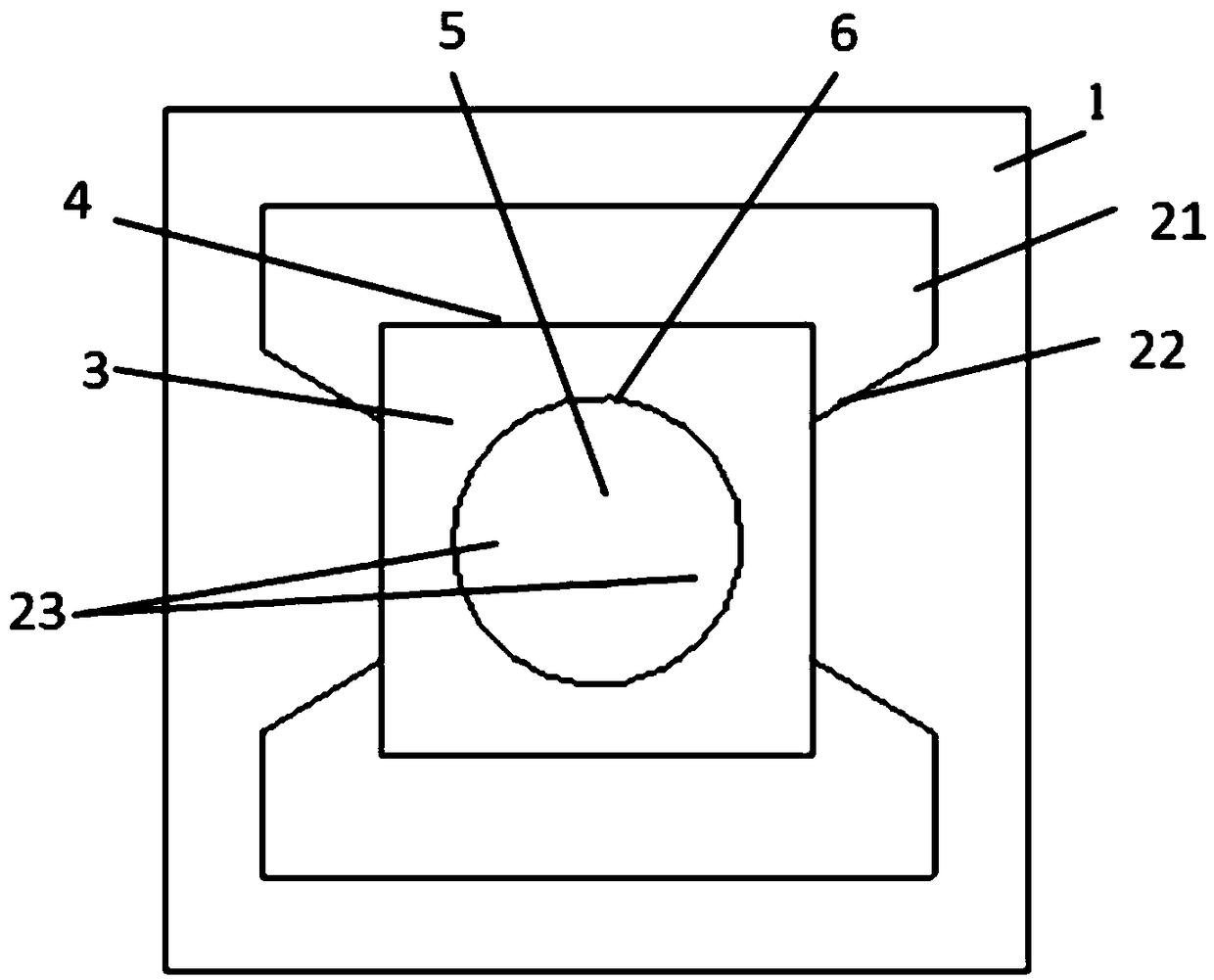

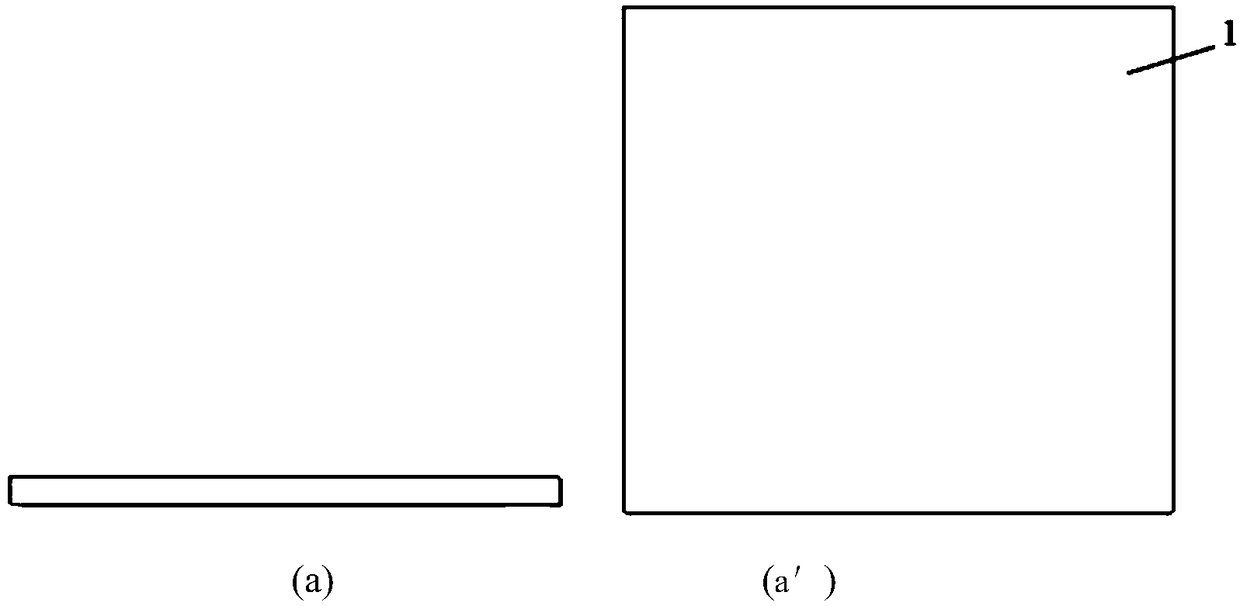

[0050] In this implementation case, an ignition circuit is designed on the basis of preparing McEFI, combined with image 3 and Figure 4 , including the following steps (Note: image 3 The left and right figures in the figure are the front view and top view of the preparation process respectively):

[0051] first step, see image 3 (a) and (a'), for 50.8mm (length) × 50.8mm (width) × 0.635mm (height) Al 2 o 3 The surface of the ceramic substrate 1 is cleaned.

[0052] The second step, see image 3 (b) and (b′), using magnetron sputtering and wet etching process on Al 2 o 3 A Cu metal layer is deposited on the surface of the ceramic substrate 1 to form pads 21 , transition regions 22 and metal bridge foils 23 . Relevant dimensions are: the width of pad 21 is 5mm-10mm; the distance from metal bridge foil 23 to pad 21 is 5mm-6mm; the size of bridge foil is 0.4mm (length)×0.4mm (width)×3.6μm (height); The disc 21 is connected to the middle of the metal layer by a transit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com