Tunnel surrounding rock temperature field test device for high-speed railway in severe cold area and burying method thereof

A technology for high-speed railways and testing devices, applied in the direction of measuring devices, thermometers, thermometers, etc., can solve problems such as damage to the tunnel structure, frost heaving, and affecting the accuracy of temperature testing, so as to ensure accurate temperature measurement, simple construction steps, and reduce The effect of small heat transfer effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

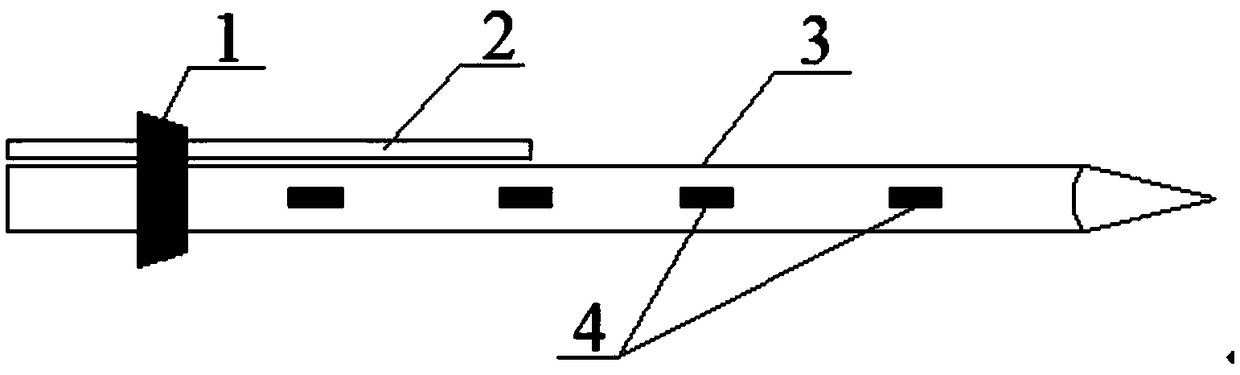

[0019] A kind of testing device for temperature field of surrounding rock of high-speed railway tunnel in severe cold area in the present invention, such as figure 1 As shown, it consists of a PPR pipe 3 and an exhaust pipe 2 arranged side by side. One end of the PPR pipe 3 is the grouting end, and the other end is the grouting end. The length of the exhaust pipe 2 is less than the length of the PPR pipe 3, the end of the exhaust pipe 2 near the grouting end is the air outlet end, and the end near the grouting end is the air inlet end;

[0020] The PPR pipe 3 and the exhaust pipe 2 are used to be placed in the temperature-measuring borehole on the inner wall of the tunnel, and the slurry outlet is located at the bottom of the borehole, and the grouting end and the outlet end of the exhaust pipe 2 are located outside the borehole; One or more temperature sensors 4 are arranged on the outer wall of the 3 along its length direction. When the PPR pipe 3 is placed in the borehole, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com