Directional low friction based large indoor self-balancing direct shear instrument and working method thereof

A self-balancing, low-friction technology, applied in the direction of using a stable shear force to test the strength of materials, instruments, scientific instruments, etc. Strength and other issues, to achieve the effect of accurate test results and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

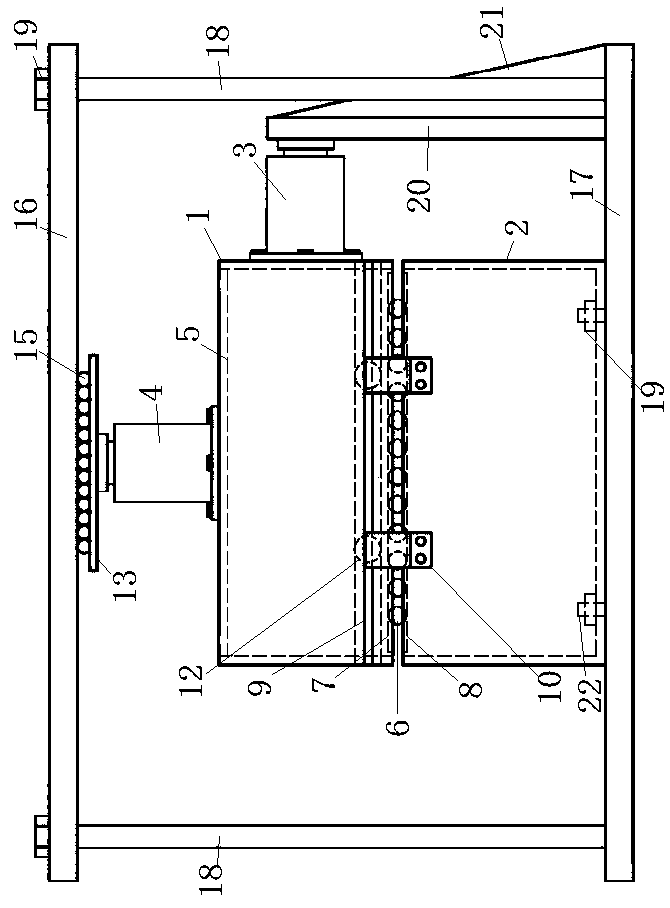

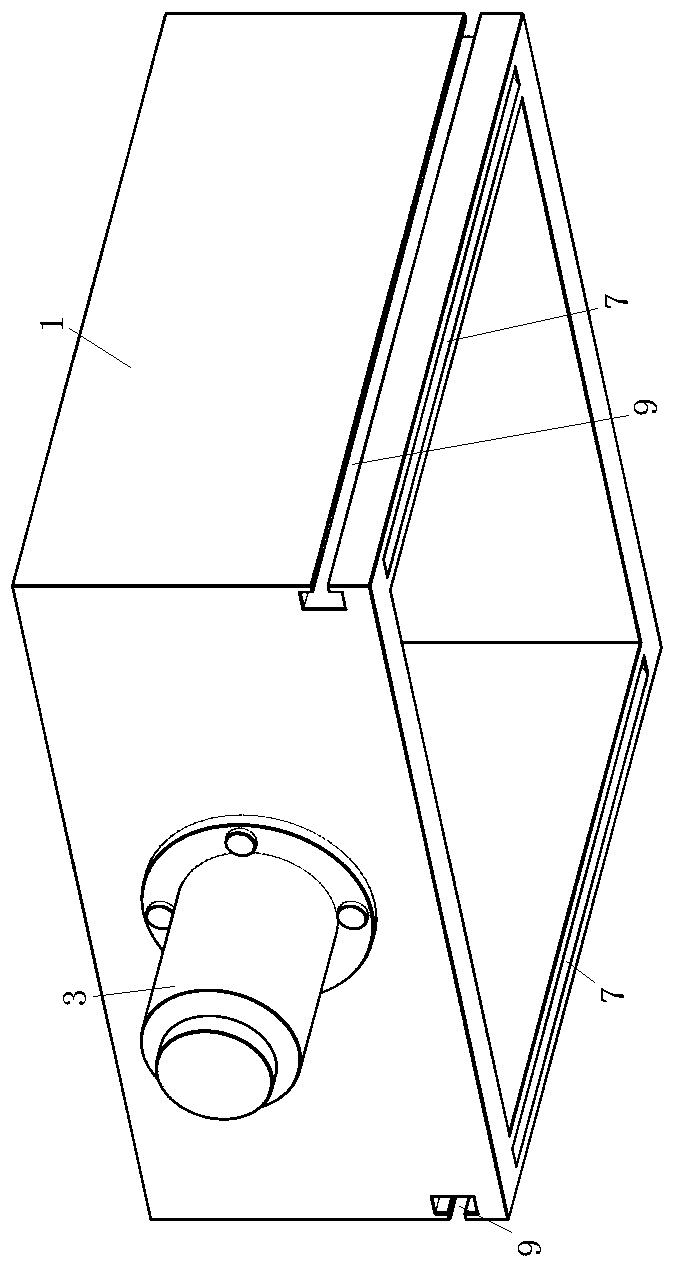

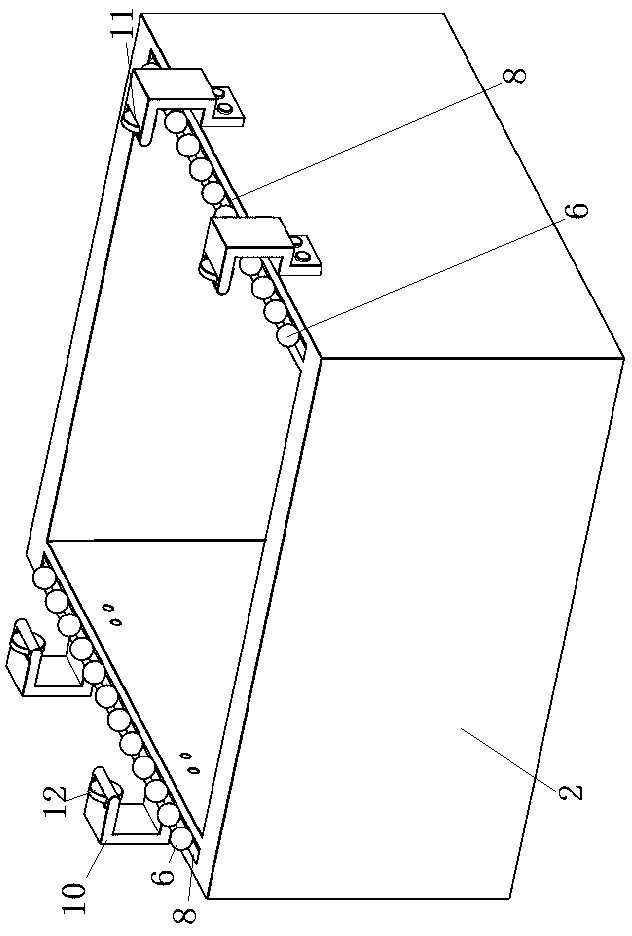

[0022] like Figure 1~5 As shown, a directional low-friction self-balancing large-scale indoor direct shearing instrument includes an upper shear box 1 and a lower shear box 2 for containing soil samples, the upper shear box has no bottom cover, and the lower The shearing box has no top cover, the bottom of the upper shearing box is supported on the top of the lower shearing box by the first rolling body and is driven by the horizontal loading jack 3 to move in translation along the shearing direction; the inner top of the upper shearing box is provided with a The vertical loading jack 4 drives the shear box cover plate 5 for lifting movement, and the top of the vertical loading jack moves in translation along the shearing direction on the frame plane above it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com