2D input-output constraint control method for intermittent process with reliance on time delay

A constraint control, input and output technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of deteriorating system control performance and affecting system stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

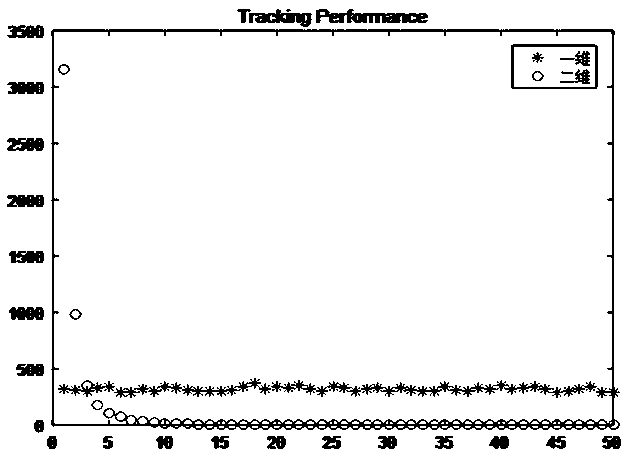

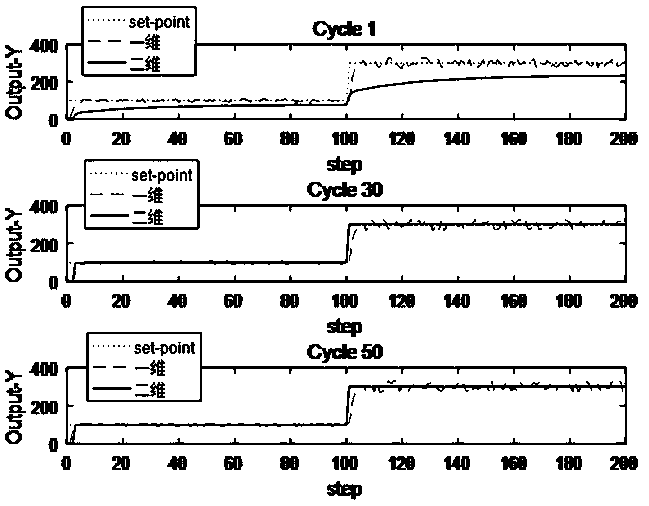

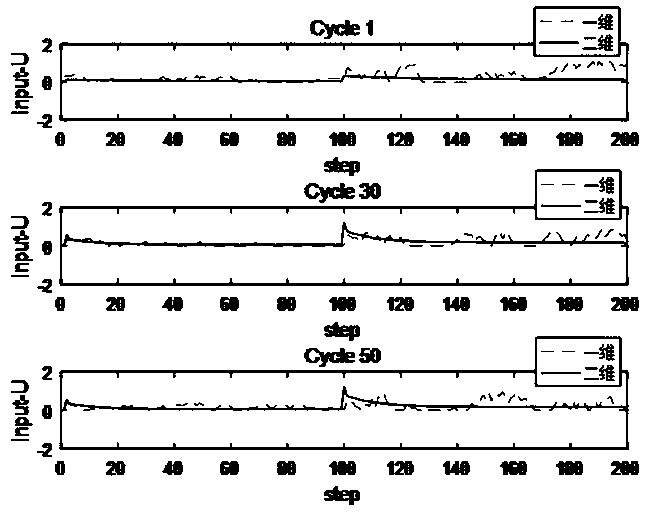

[0156] The invention takes the injection molding process as a representative to carry out the experiment of the batch process with uncertain disturbance and state time lag. The injection molding process is a typical batch process, which mainly includes three stages: injection stage, pressure holding stage and cooling stage. In the pressure holding stage, the key variable is the cavity pressure, which must be controlled according to the pre-set trajectory to ensure the quality of the product. Changes in working conditions such as molds, materials, and dynamic characteristics of hydraulic actuators will make the pressure-holding stage an intermittent process with uncertain disturbances. In the pressure-holding stage, traditional iterative learning controllers (hereinafter referred to as ILCs) such as P-type ILCs are not applicable. On the other hand, when using slow pressure valves, the control performance tends to be poor. Pure feedback control, such as proportional-integral-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com