A design method of a turbofan ramjet combined engine with an external culvert and a built-in rocket

A technology of turbofan engine and design method, which is applied in the direction of combined engine, ramjet engine, mechanical equipment, etc. It can solve the problem that it is difficult to meet the thrust demand of aircraft, the working Mach number of the ramjet engine cannot be lowered, and the working Mach number of the turbine engine cannot be increased, etc. problems, to achieve the effect of improving overall performance, moderate technical difficulty, and simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

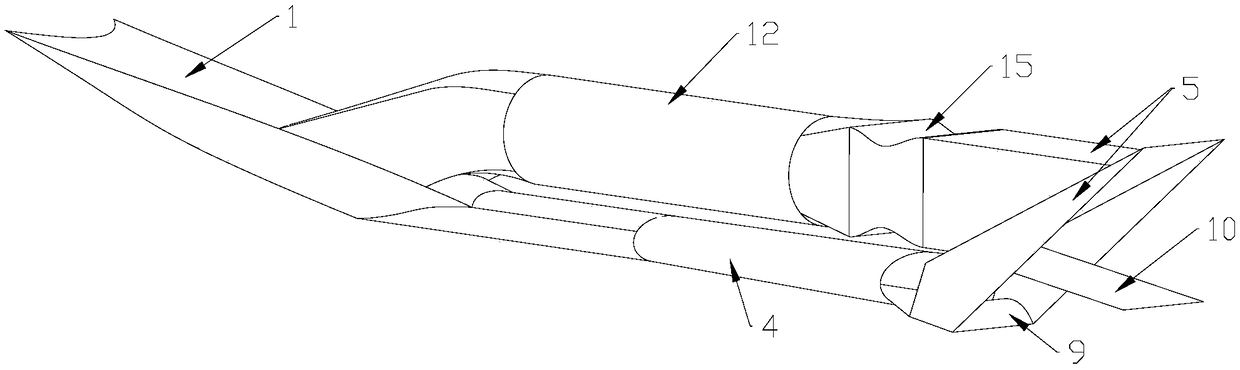

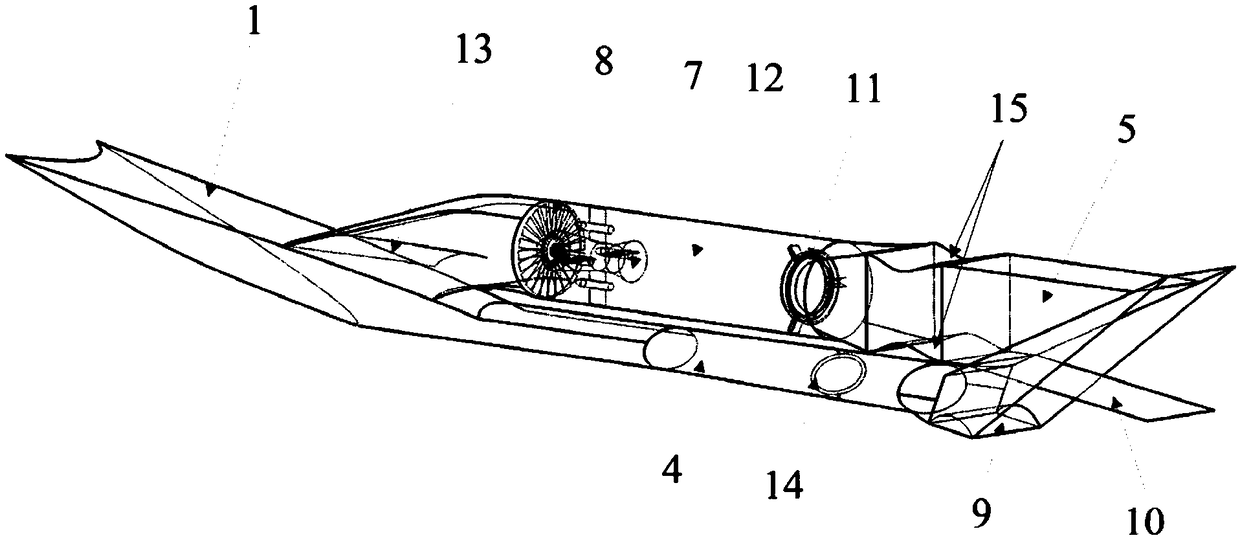

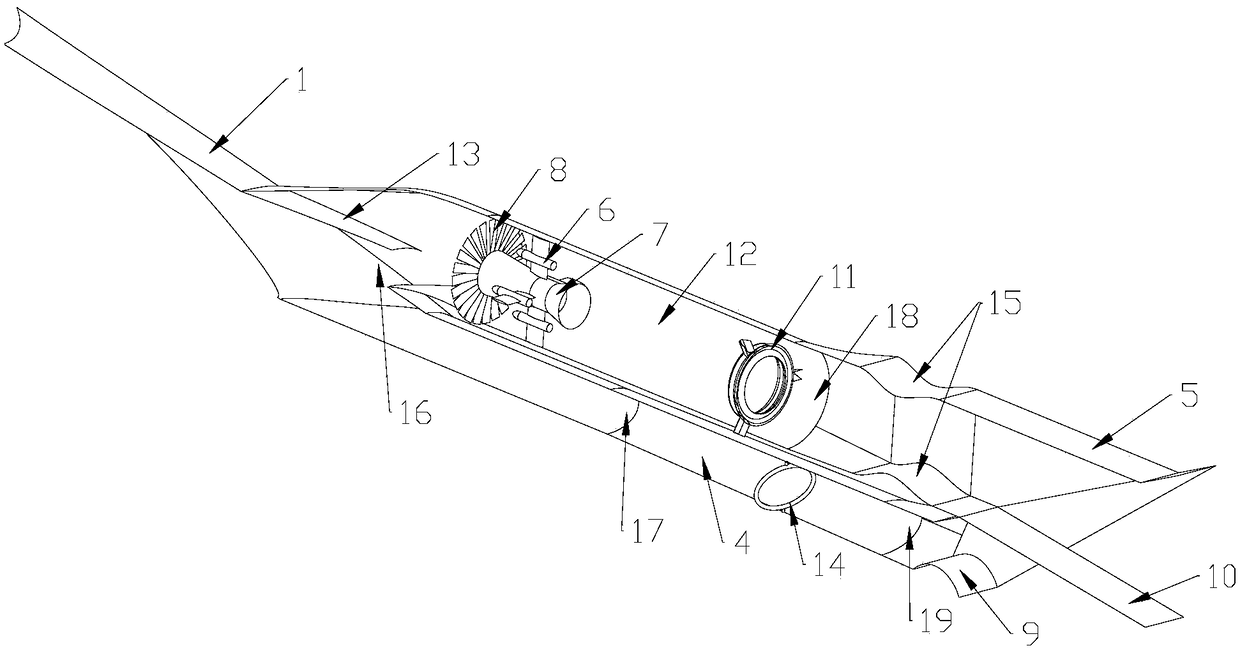

Image

Examples

Embodiment Construction

[0040] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0041] A design method for a turbofan ramjet engine with a built-in rocket, comprising the following steps:

[0042]1) Formulate the overall performance requirements of the engine according to the flight mission, design the basic flow field of the inlet based on the overall performance requirements, and then obtain the three-dimensional inward turning inlet by performing streamline tracing in the basic flow field;

[0043] 2) Obtain the inlet and outlet parameters of the scram chamber according to the overall performance of the engine, and design the scram chamber at the outlet of the three-dimensional internal turning inlet described in step 1);

[0044] 3) Based on step 2) SFC combustion chamber parameters and en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com