RGB LED integrated packaging module

A technology of integrated packaging and chips, applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of complex structure and numerous connecting pins, reduce connecting pins, facilitate maintenance and replacement, improve practicability and applicability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

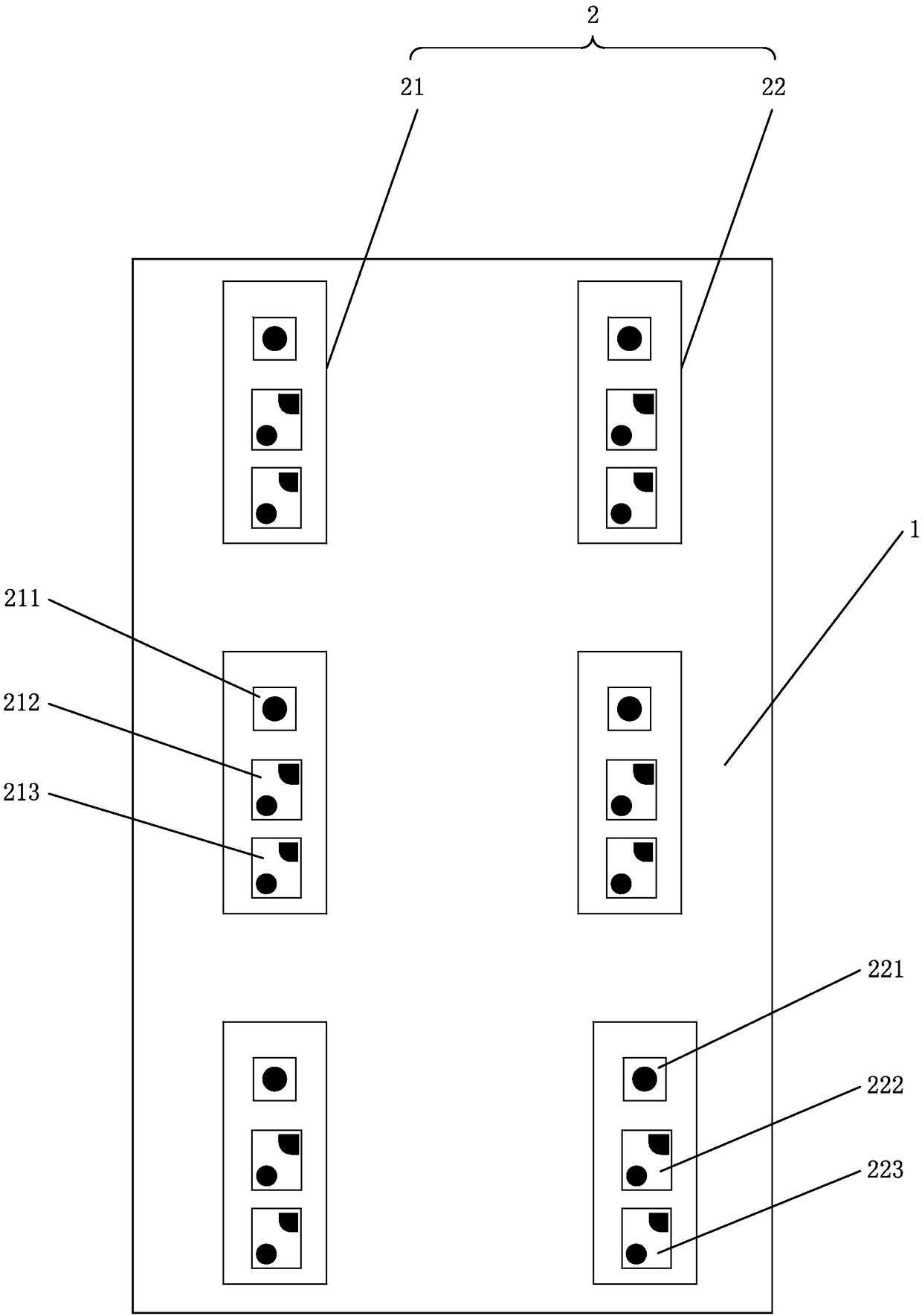

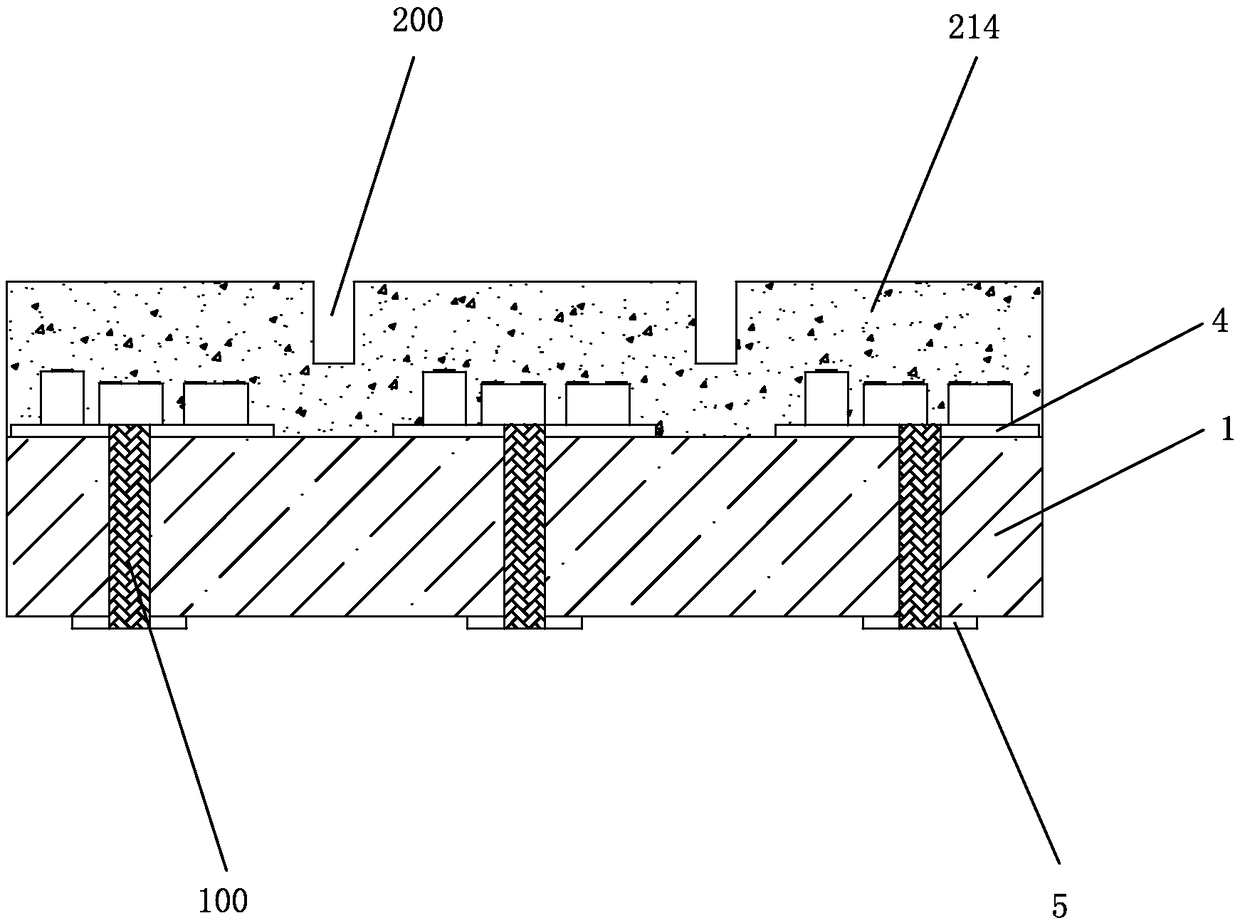

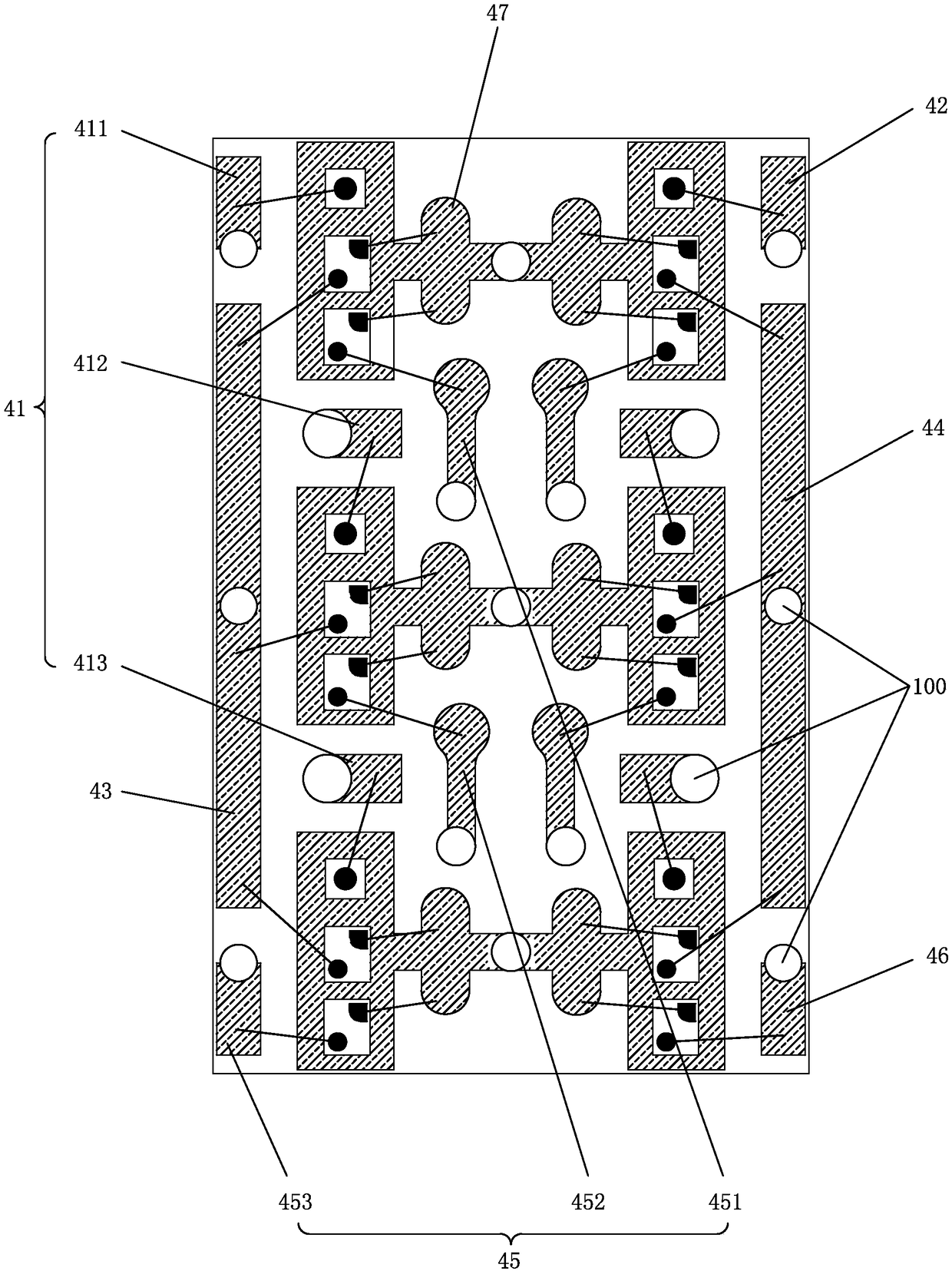

[0058] Such as Figure 1 to Figure 6 As shown, each of the light emitting groups 2 includes a first light emitting unit 21 and a second light emitting unit 22 , and the first light emitting unit 21 includes a first red chip 211 , a first green chip 212 and a first blue chip 213 . The second light emitting unit 22 includes a second red chip 221 , a second green chip 222 and a second blue chip 223 . The first electrode of the first red chip 211 in each of the light-emitting groups 2 is connected in parallel with the first electrode of the first green chip 212 and the first electrode of the first blue chip 213 to form a first Parallel branch, the first electrode of the second red chip 221 in each of the light-emitting groups 2 is connected in parallel with the first electrode of the second green chip 222 and the first electrode of the second blue chip 223 And a second parallel branch is formed, and the second parallel branch is connected in parallel with the first parallel branc...

Embodiment 2

[0069] Embodiment 2, its difference with embodiment 1 is:

[0070] Such as Figure 7 As shown, the front homopolar region 47 is a common anode region. The first R region 41 is arranged symmetrically with the first two R regions 42 , and it includes the second upper front R region 414 located on the rear side of the first light-emitting unit 21 on the uppermost side, and the first light-emitting region 414 located in the middle. The second middle front R region 415 on the rear side of the unit 21, and the second lower front R region 416 located on the rear side of the first light-emitting unit 21 in the lowermost layer. The previous B zone 45 is arranged symmetrically with the first two B zones 46, and it includes the second upper previous B zone 454 located on the lower right side of the second upper previous R zone 414, and the second upper previous B zone 454 located at the second The second middle front B region 455 on the lower right side of the middle front R region 415...

Embodiment 3

[0071] Embodiment 3, its difference with embodiment 1 is:

[0072] Such as Figure 8 with Figure 9 As shown, the number of the light-emitting groups 2 is 2 groups, which are arranged sequentially from top to bottom, and also include a third light-emitting unit 23 arranged between the first light-emitting unit 21 and the second light-emitting unit 22, The third light emitting unit 23 includes a third red chip 231 , a third green chip 232 and a third blue chip 233 .

[0073] The previous R zone 41 includes a total previous R zone 417 located on the left side of the first light emitting unit 21 on the upper side, a separate previous R zone 418 located on the right side of the first light emitting unit 21 on the upper side, and a separate previous R zone 418 located on the right side of the first light emitting unit 21 on the upper side. The lower part of the first light-emitting unit 21 on the right side is the next R region 419 .

[0074] The previous G zone 43 includes a to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com