Tight arrangement wire spring socket and processing method

A wire spring jack and processing method technology, which is applied in the manufacturing of contacts, electrical components, coupling devices, etc., can solve the problems of low reliability, large size of the wire spring jack, and inability to better meet the transmission of micro-current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

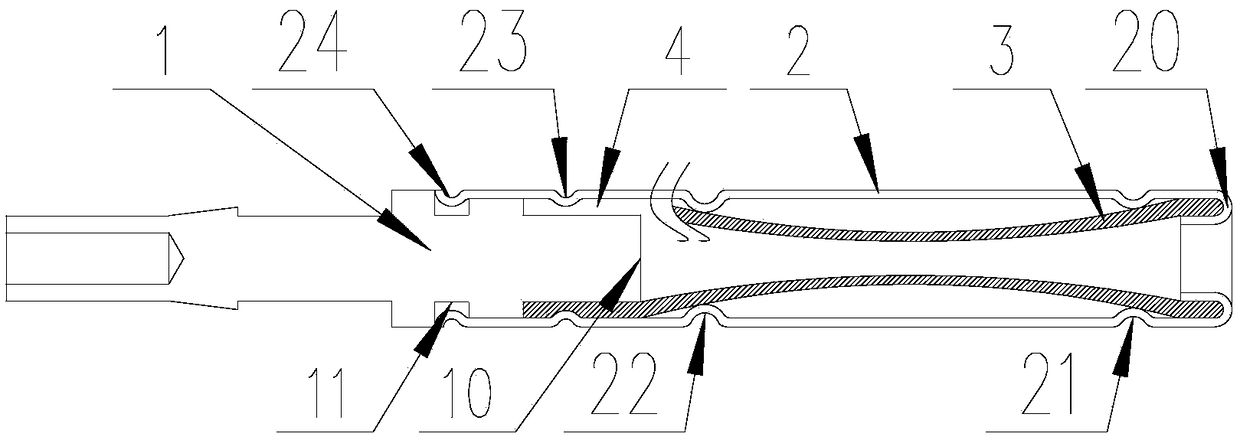

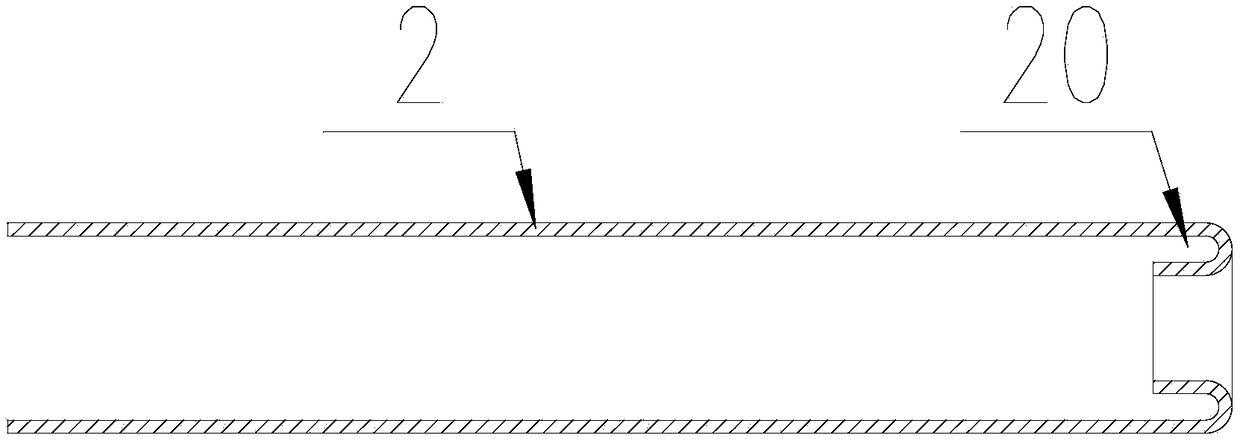

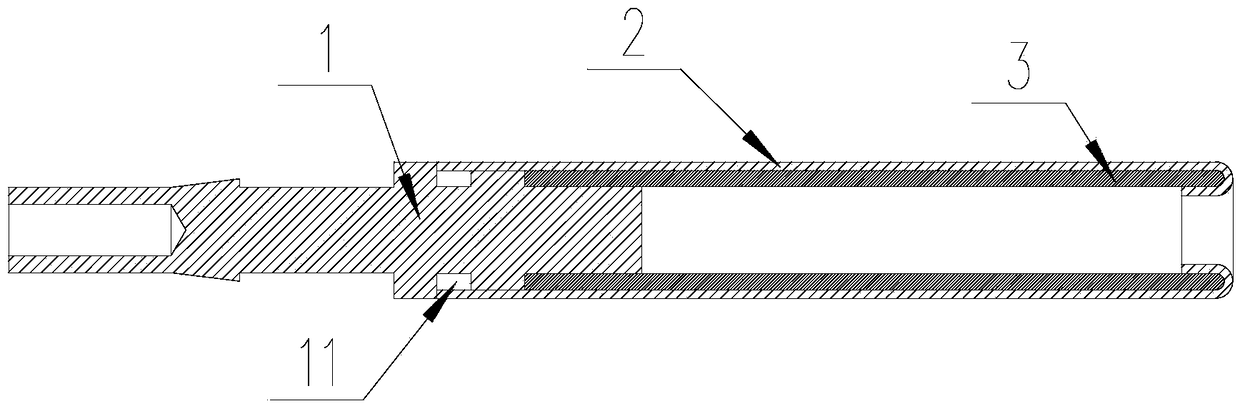

[0045] Such as Figure 1-Figure 3 As shown, a close-packed wire spring socket, a close-packed wire spring socket, includes a front cover 2, a rear cover 1 and a wire spring wire 3, and the front port of the front cover 2 is bent inward to form a U-shape slot 20, the front end of the back cover 1 is plugged into the rear end of the front cover 2, one end of the wire spring wire 3 is connected to the front end of the back cover 1, and the other end of the wire spring wire 3 is inserted into the In the U-shaped groove 20.

[0046]The front end of the front cover 2 is bent to form a U-shaped groove 20, and the wire spring wire 3 is directly inserted into the U-shaped groove 20 without bending at the front end of the front cover 2, which is different from the existing densely wound hyperboloid wire spring socket. The wire spring wire 3 of the prior art is bent at the mouth of the sleeve, and in the process of inserting and pulling out the pin, due to the up and down friction with ...

Embodiment 2

[0056] Such as Figure 1-Figure 3 As shown, a method for processing densely packed wire spring sockets includes the following steps:

[0057] Step 1: Processing front cover 2;

[0058] Step 2: Bending one end of the front cover 2 to form a U-shaped groove 20;

[0059] Step 3: Set 1 after processing;

[0060] Step 4: Insert the front end of the rear cover 1 into the front cover 2;

[0061] Step 5: Connect one end of the spring wire 3 with the back cover 1;

[0062] Step 6: Insert the other end of the spring wire 3 into the U-shaped groove 20;

[0063] Step 7: Crimp the front sleeve 2 and the rear sleeve 1.

[0064] Processing the rear sleeve 1 in the step 3 includes: processing an annular step 10 at the front end of the rear sleeve 1 and processing an annular groove 11 in the middle, inserting one end of the annular step 10 into the front sleeve 2, the annular groove The groove 11 is flush with the end of the front cover 2 , and one end of the centerline spring wire 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com