Brush frame assembly and assembling method thereof

A brush holder and assembly technology, which is applied in the field of auto parts, can solve the problems of low compressive strength and achieve the effects of high compressive strength, high structural strength and high assembly precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

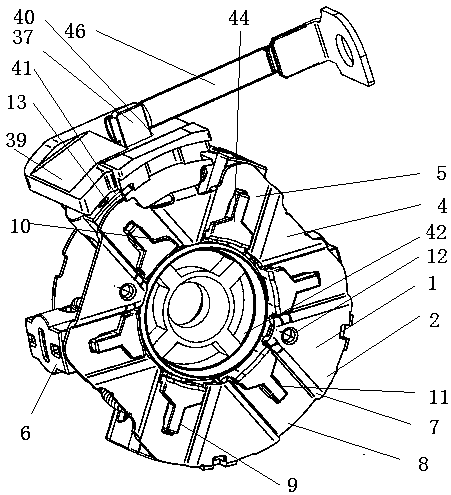

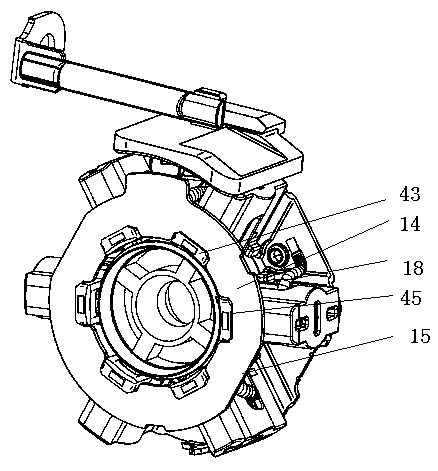

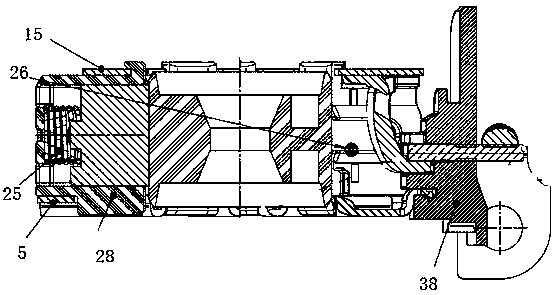

[0038] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 with Figure 7 As shown, a brush holder assembly provided by the present invention includes: a lower bottom plate assembly 1, which includes a bottom bottom plate 2 and three first brush holder assemblies 3; the three first brush holder assemblies are welded On the bottom plate; the lower bottom plate includes six concave plates 4 and six arched bosses 5, the six concave plates and the six convex plates are staggered and connected together, and the six bosses are all on the same concave plate Side; the first brush holder assembly is welded to the dome of the boss. The first brush holder assembly is covered with a brush box 6. The six concave plates are at the same level, and the tops of the six bosses are at the same level.

[0039] The convex plate is triangular; the convex platform includes arcuate side walls 7 on both sides and a top wall 8 located at the end of the arcuate side walls; the top w...

Embodiment 2

[0046] As attached Figure 8 As shown, the present invention also discloses a brush holder assembly assembly method, which includes the following steps:

[0047] 1) Weld the first brush holder assembly on the lower base plate to make the lower base plate assembly;

[0048] 2) Weld the second brush holder assembly on the upper base plate;

[0049] 3) Weld the lug assembly onto the welding line side of one of the second brush holder assemblies in the bottom plate to make the upper bottom plate assembly;

[0050] 4) Install the welded lower bottom plate assembly on the positioning tooling, where the positioning tooling includes a cylindrical base 47 with a mounting hole 50 in the middle, and a pair of limit posts 48 matching the positioning holes are installed on the upper end of the cylindrical base , The center of the mounting hole is equipped with a top column 49, the bottom end of the base is fixedly connected to the elevator 51, the base can move up and down relative to the top col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com