Frozen confection manufacture

A technology for frozen desserts and non-sugar sweeteners, applied in frozen desserts, edible oil/fat, cocoa, etc., can solve problems such as high investment, and achieve the effect of low investment, simplicity and investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

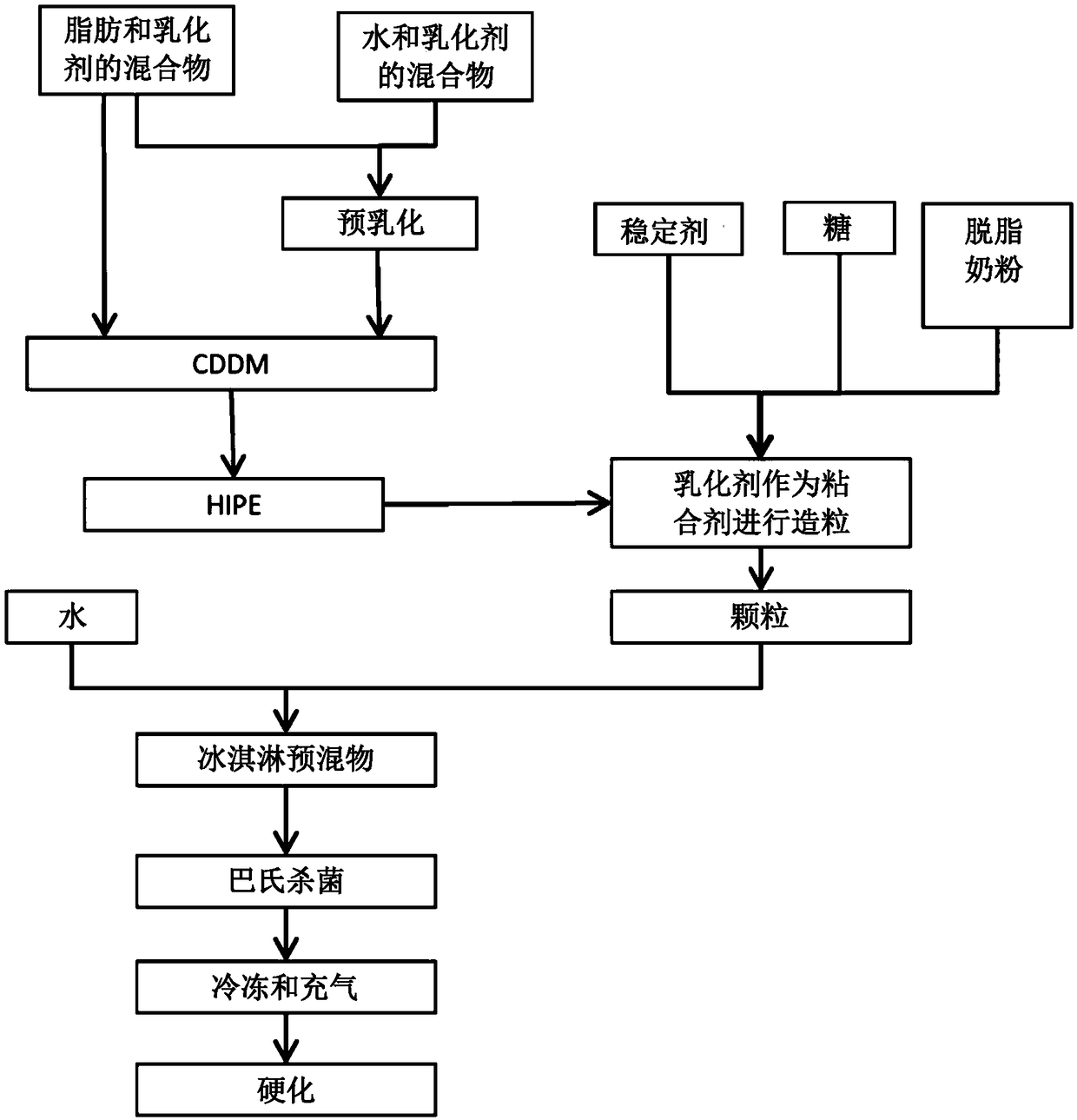

Method used

Image

Examples

Embodiment 1

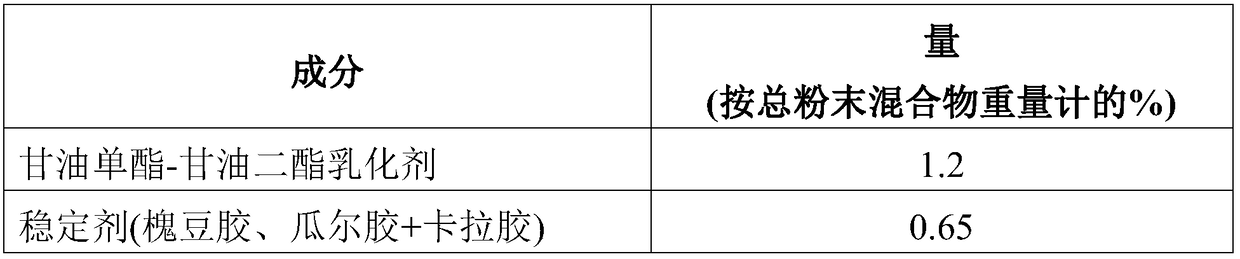

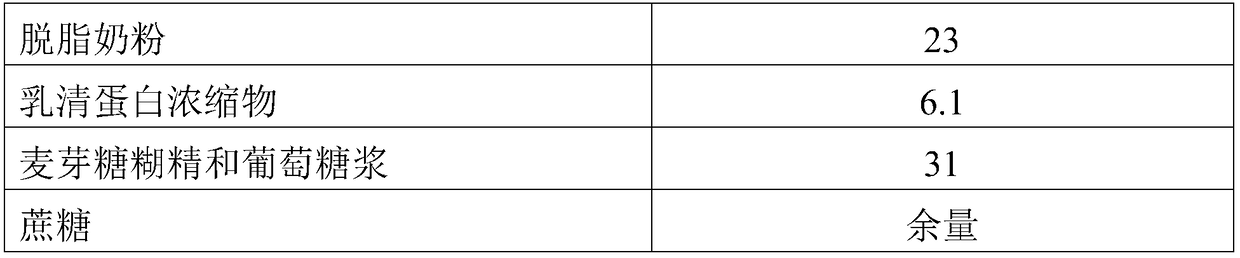

[0097] This example illustrates the formation of a concentrate in the form of granules, where a concentrated emulsion is used as a binder, with sufficient fat content to avoid any need for drying to produce stable granules.

[0098] A water phase, an oil phase, and an emulsion were prepared, and the oil phase and emulsion were combined to form the HIPE as described below. Table 2 shows the composition of HIPE.

[0099] Table 2

[0100] Element

% by weight of emulsion

76

Monoglycerides - Diglycerides

3

sodium caseinate

3

water

18

[0101] Aqueous phases, oily phases and emulsions were prepared according to the following methods:

[0102] 1.1 Place a 2L steel container on a hot plate and add 0.425kg of boiling water to it. Slowly add 75g sodium caseinate to boiling water while stirring with an IKA ULTRA-TURRAX T18 with S18N–19G dispensing element. Stirring was continued until the sodium caseinate was visua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com