Picking machine and picking method for fruit of Paeonia suffruticosa

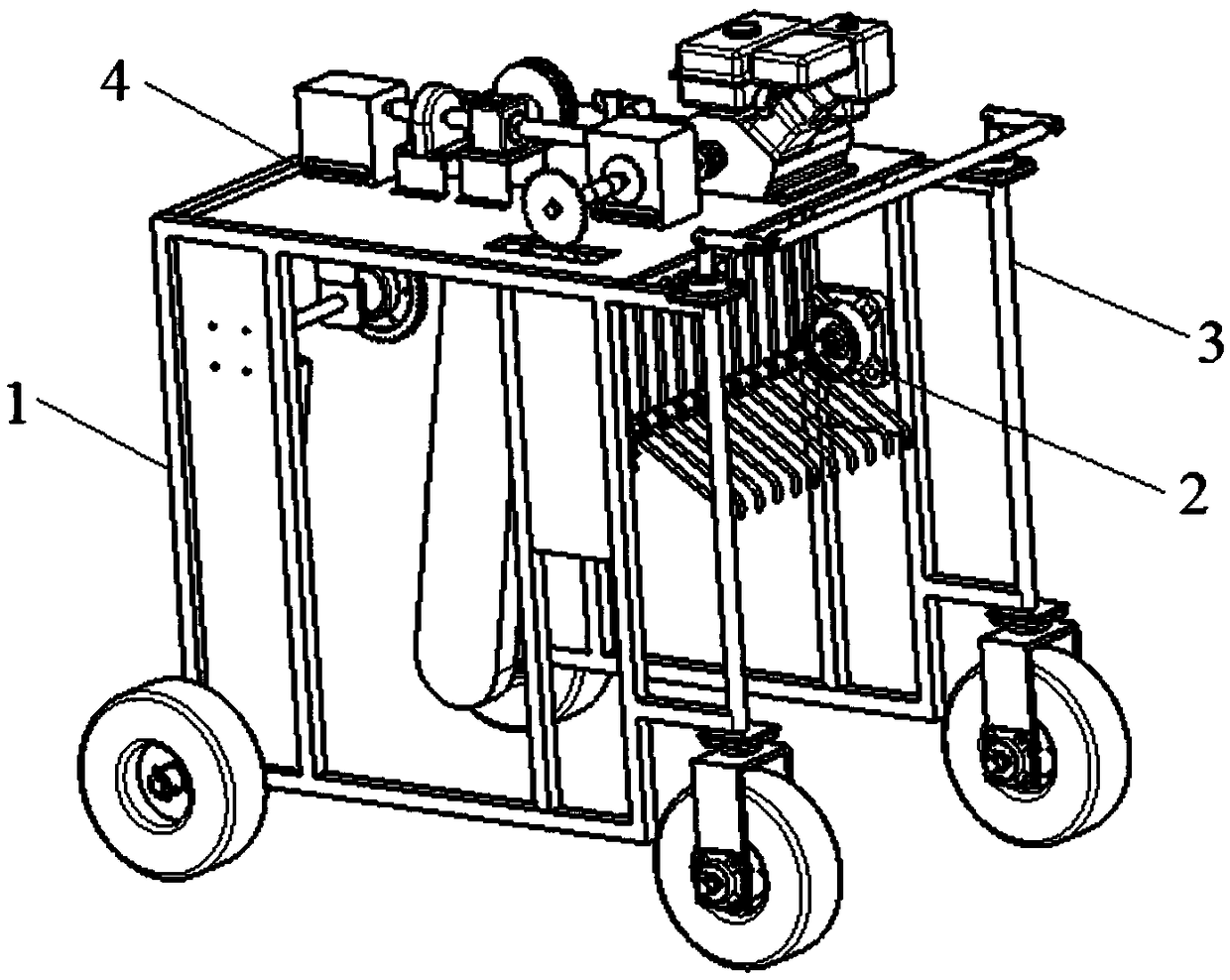

A technology for peonies and picking machines for oil, which is applied in the field of agricultural machinery, can solve the problems of picking platform noise, large vibration, affecting the normal operation of picking machines, and the picking devices cannot be used universally, so as to solve the differences in plant height and plant distance and be easy to promote , the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0142] Two acres of oil peony plants are picked and processed with the oil peony fruit picking machine provided by the invention, comprising the following steps:

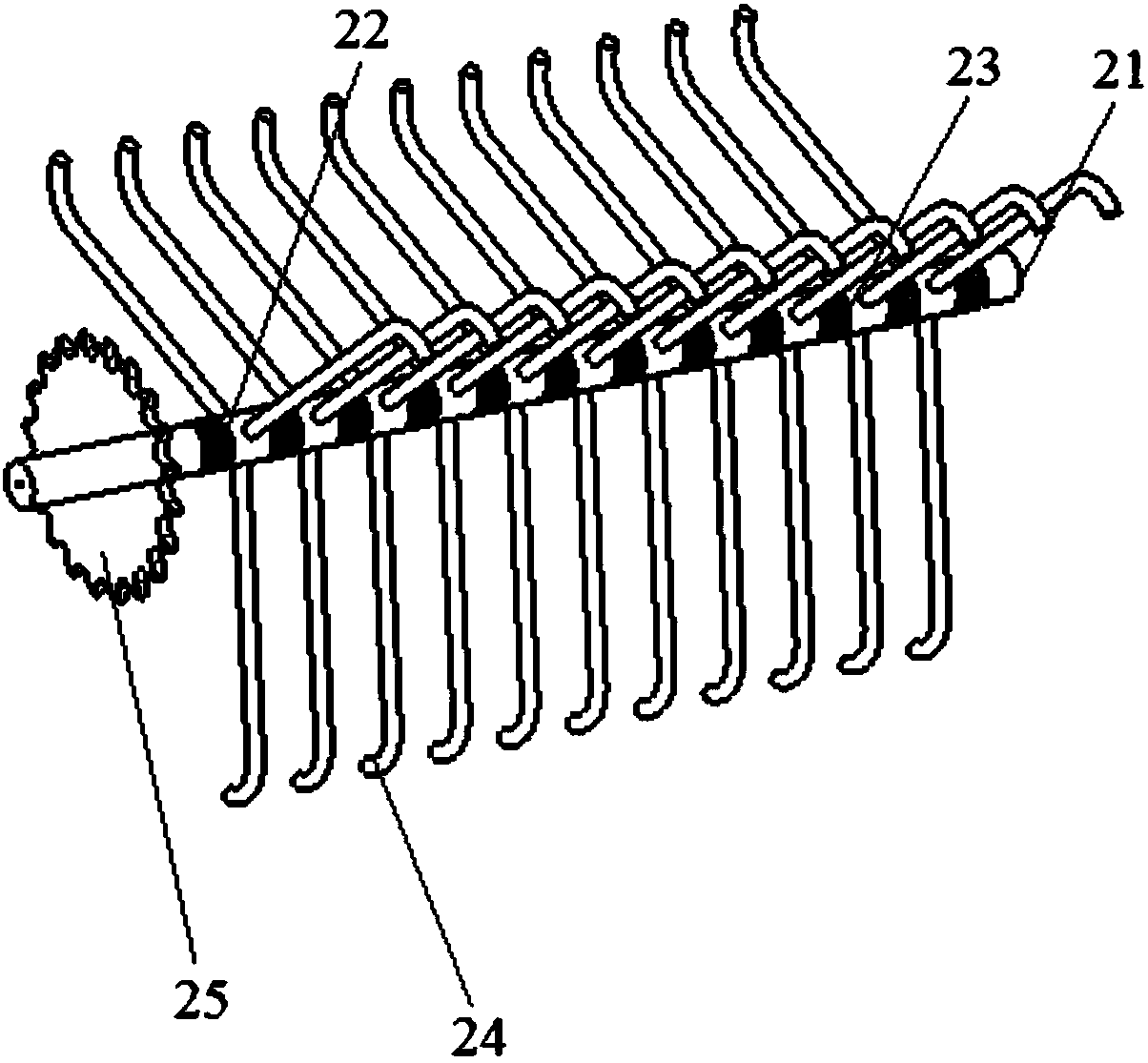

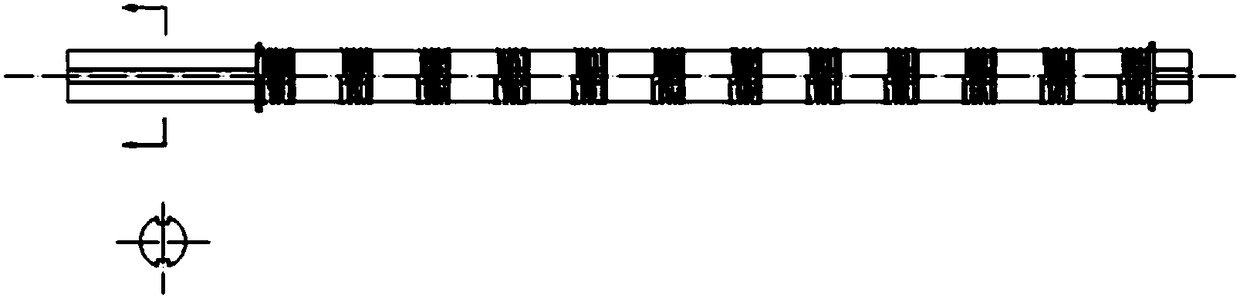

[0143] 1) According to the size of the peony plants to be picked for oil described in Table 1, the number of sleeves of the peony fruit picking machine for oil is set to 11, and the distance between each pair of comb teeth in the axial direction is designed to be 60 mm. The material used for the comb teeth is No. 45 steel;

[0144] Table 1 Partial size of peony plant for oil

[0145] serial number

1

2

3

4

5

6

7

8

9

10

average

Fruit diameter (mm)

65

88

72

92

66

83

79

75

80

75

77.5

Number of branches (branches)

8

4

5

7

6

5

7

4

6

5

5.7

Angle between branch and stem (°)

76

84

64

97

103

95

81

92

88

83

86.3

[0146] 2) Adjust the steering device 3 so that ...

experiment example 1

[0154] The picking process in embodiment 1 and comparative example 1 is carried out 3 parallel experiments, and the results are shown in the table below:

[0155] Table 2 Results of picking and processing peony plants for oil

[0156]

[0157] in,

[0158]

[0159]

[0160] As can be seen from Table 2, compared with Comparative Example 1, the picking amount of peony fruit for oil in Example 1 has increased by 15.93% on average, the picking rate has increased by 15.87% on average, the fruiting rate in the next year has increased by 9.10% on average, and the plant damage rate has increased by an average of 15.87%. A reduction of 47.62%.

[0161] In summary, using the picking machine provided by the invention to pick peony fruits for oil can increase the picking rate up to 74.9%, the damage rate down to 5.6% at the lowest, and the fruiting rate in the next year up to 90.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com