Acid-bitterness removal tank used in process of juice processing

A processing and deacidification technology, applied in food adsorption, food science and other directions, can solve the problems of the influence of the taste of the finished fruit juice, the insufficient contact between the adsorption resin and the fruit juice, and the sour and bitter taste of the finished fruit juice. Bitter effect, taste guarantee, effect of expanding contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

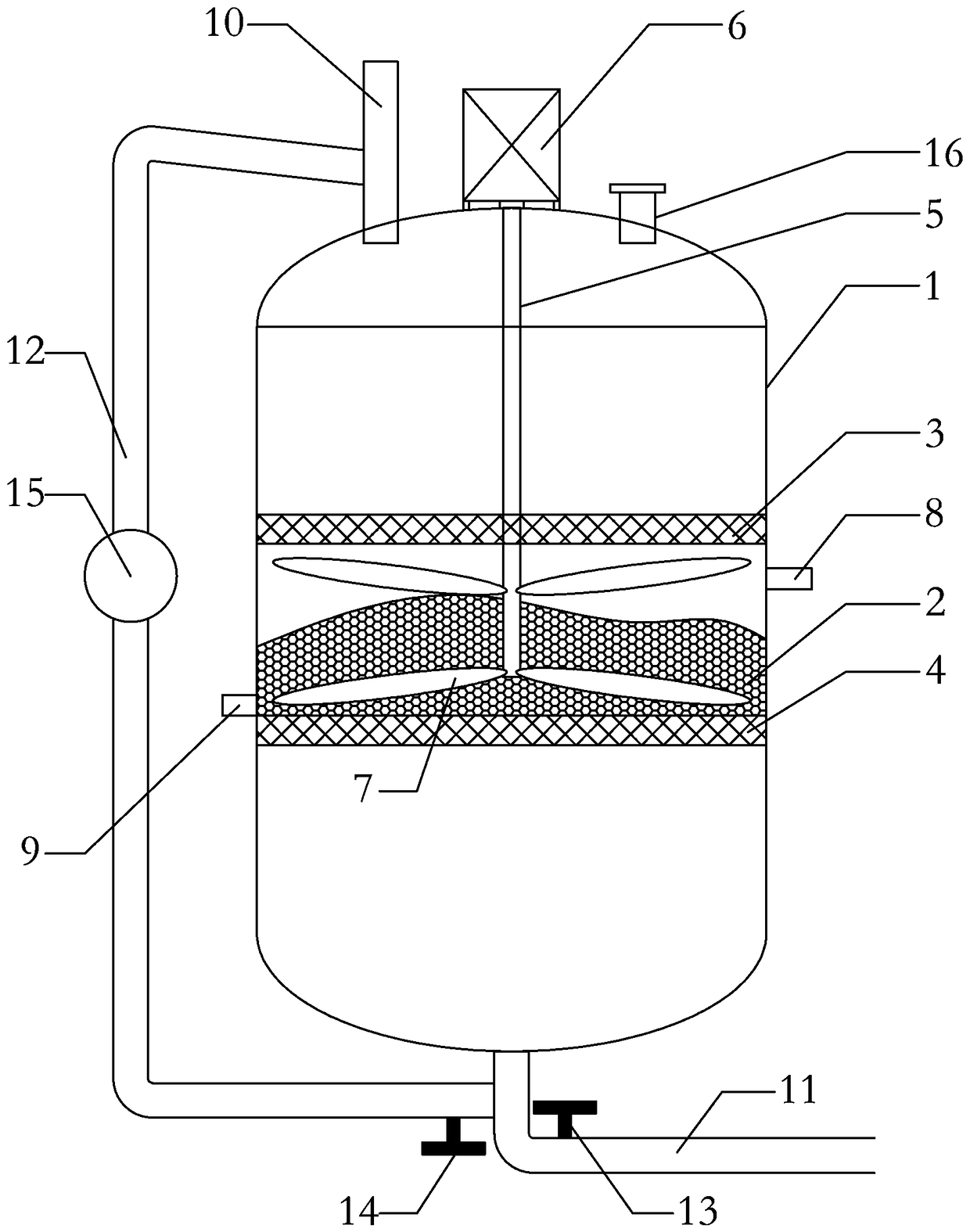

[0017] As shown in the figure, a deacidification and debittering tank used in fruit juice processing includes a tank body 1, a feed pipe 10 is provided on the top of the tank body 1, a discharge pipe 11 is provided at the bottom of the tank body 1, and a tank body 1 is provided with a The upper filter screen 3 and the lower filter screen 4 are filled with adsorption resin 2 between the upper filter screen 3 and the lower filter screen 4. The top of the tank body 1 is provided with a drive motor 6. The output shaft of the drive motor 6 is connected to the stirring shaft 5, and the stirring shaft The lower end of the 5 extends into the space between the upper filter screen 3 and the lower filter screen 4, and the stirring blade 7 is arranged on the stirring shaft 5 between the upper filter screen 3 and the lower filter screen 4.

[0018] In a preferred solution, the side wall of the tank body 1 is provided with a resin addition port 8 and a resin discharge port 9, the resin addit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com